Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 33

Thread: Wadkin Xmas

-

28th December 2012, 06:51 PM #16

Ha, stepped out for a moment and missed all the fun !

Tony, I was just going to check with my friend on Monday and get a price, but I tell you what, your self and Cam are on to something for sure !!

Hard to beat that..

Ill keep you posted any way, just for piece of mind....

Melbourne Matty.

-

28th December 2012 06:51 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

28th December 2012, 09:29 PM #17

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Matty,

I would definitely be interested in what your mate would have to say (just in case), it would be good to know what the modern equivalent would be rated to the 10000 rpm. It's easy to search for a good price, but without the knowledge or a model number, it's a lot harder.

cheers,

camo

-

29th December 2012, 10:22 PM #18

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- geelong

- Posts

- 125

Here are a few snaps of the spindle and componentry.

I have reassembled it so i dont lose or forget anything;it only weighs 28 kg!

The three speeds on the name plate have me stumped;it is a single speed 2880rpm motor with 6 and 4.5 inch pulleys driving a 3 inch spindle pulley.

No evidence of any alterations to anything.

Matty;advice from your colleague would be valuable particularly re the high speed version of 6311.

Camo;have you original spanners with your EQ? I am making do with a 26in shifter from the tractor toolkit and needing the full 26. By the way the nuts are all right hand thread except the one on the base of the spindle.(anti clockwise spindle rotn)

Cheers

Tony

-

30th December 2012, 12:57 AM #19

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Tony,

Came with 3 spanners, 2 opened ended, the closed ended spanner was clearly from another piece of equipment at Lucus heights, anyone missing a spanner for their Robinson (no size stamped on it)? I am not sure if the others are original Wadkin issue, the two open ended spanners have “Lion Brand” stamped on them, and the closed end has “Thomas Robinson & Son Ltd Rochdale England”.

(no size stamped on it)? I am not sure if the others are original Wadkin issue, the two open ended spanners have “Lion Brand” stamped on them, and the closed end has “Thomas Robinson & Son Ltd Rochdale England”.

Matty now is your time to truly shine, I expect a scanned catalogue showing the original “contents of carton” for the Wadkin EQ, with detailed sketches of the spanners supplied .

.

I put the pepsi can in for scale, the big one is 1¾ BSW, 1 7/8 BSF for the spindle, the other open ended spanner is 1¼ BSW, 1 3/8 BSF for the spindle nut for cutters, and the closed ended spanner has no size on it.

spanners1.jpgspanners4.jpgspanners2.jpgspanners3.jpgspanners5.jpg

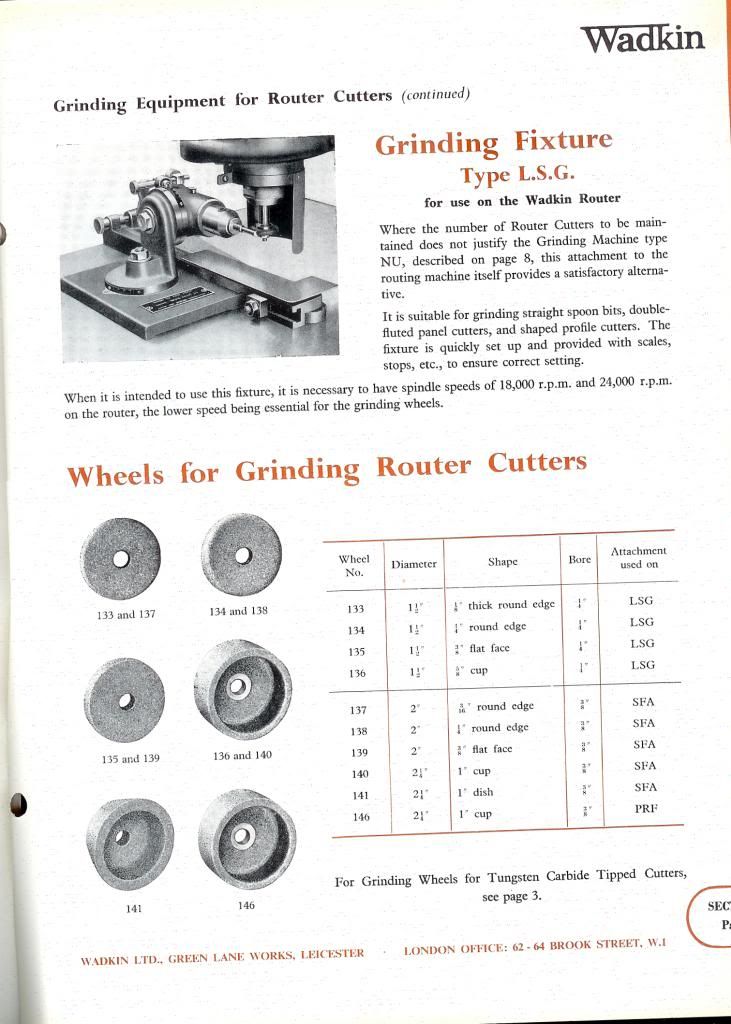

I managed to get lots of goodies with my EQ, I have been meaning to pull my finger out and list it with photos of everything. I am going to need some help confirming what does and doesn't go with the EQ, for example after some head scratching and google searching I determined this had nothing to do with the EQ

LS500 jig.jpg

A sharpening jig (optional extra) for the Wadkin LS router. I must admit the sign makes more sense now (I kept thinking, but the EQ only goes up to 10000 rpm, what the hell does the sign mean ). Now all I need to find is a Wadkin LS to go with my sharpening jig

). Now all I need to find is a Wadkin LS to go with my sharpening jig .

.

Cheers,

Camo

-

30th December 2012, 09:41 AM #20

Your a hard man Camo...lol

The back of the catalog brochure that I have scanned and posted previously is a good place to start....

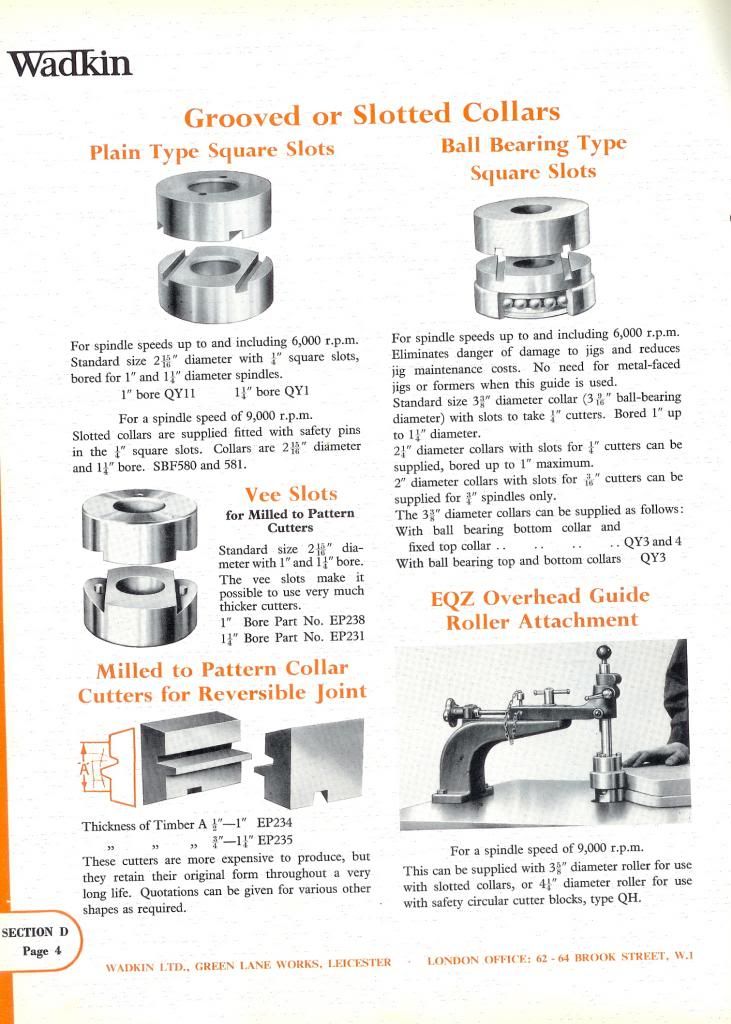

1/ 5hp motor complete with suitable control gear.

*Which I'm sure you have...

2/ 1 1/4 (31-75 mm) diameter loose top pieces.

*Top of the page, pictured below.

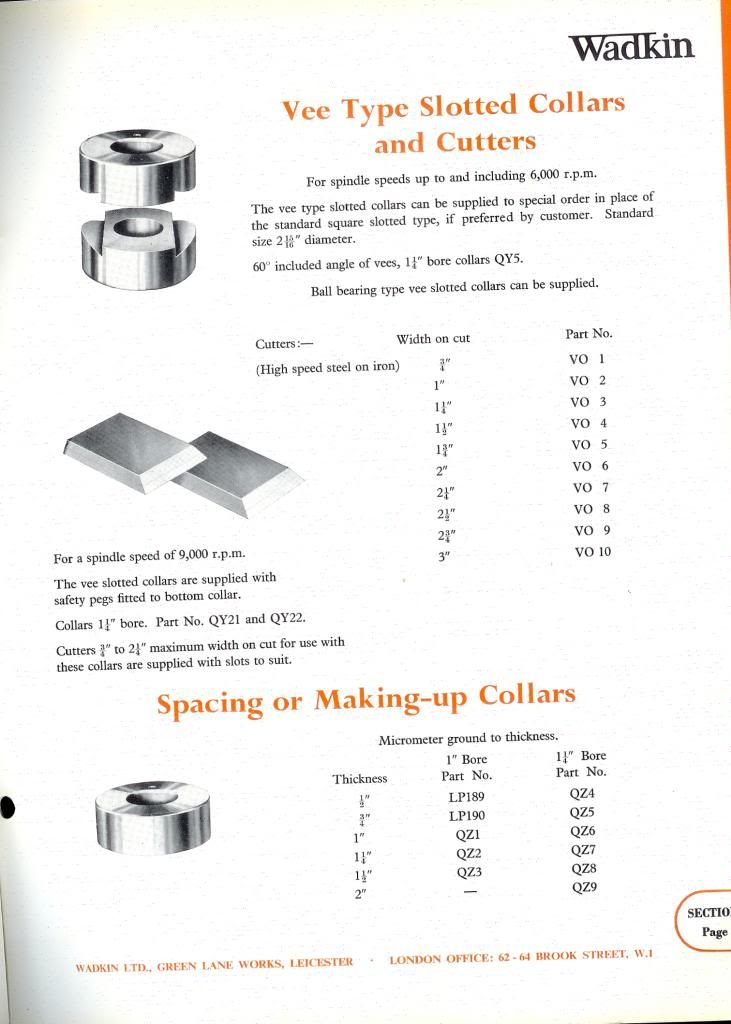

3/ Grooved cutter collars. Spacing collars.

* Pictured below.

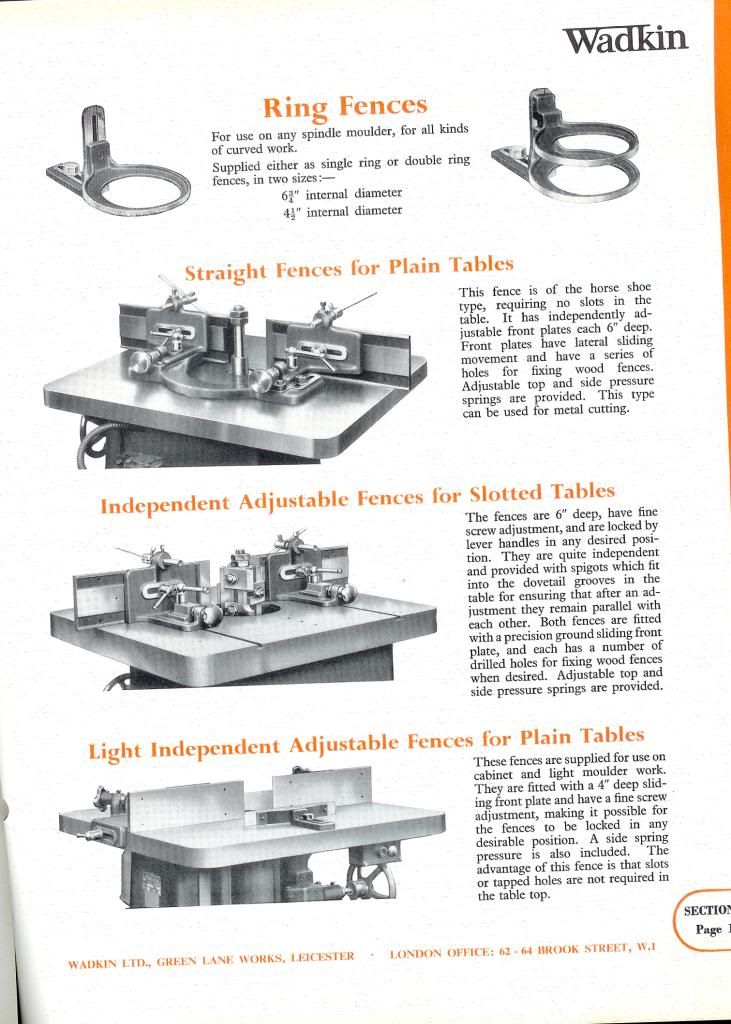

4/ Independent adjustable fences.

*Middle of the page pictured below.

5/ Top and side pressure springs.

* Also pictured above.

6/ Set of Spanners.

* Here's where I let you down a bit Cam, "no pic", but I do know there should be at least 4 off.

One large one for the hold down nut.

two for the fences, and one for maintenance.

Jack may be able to shed more light on the situation too....

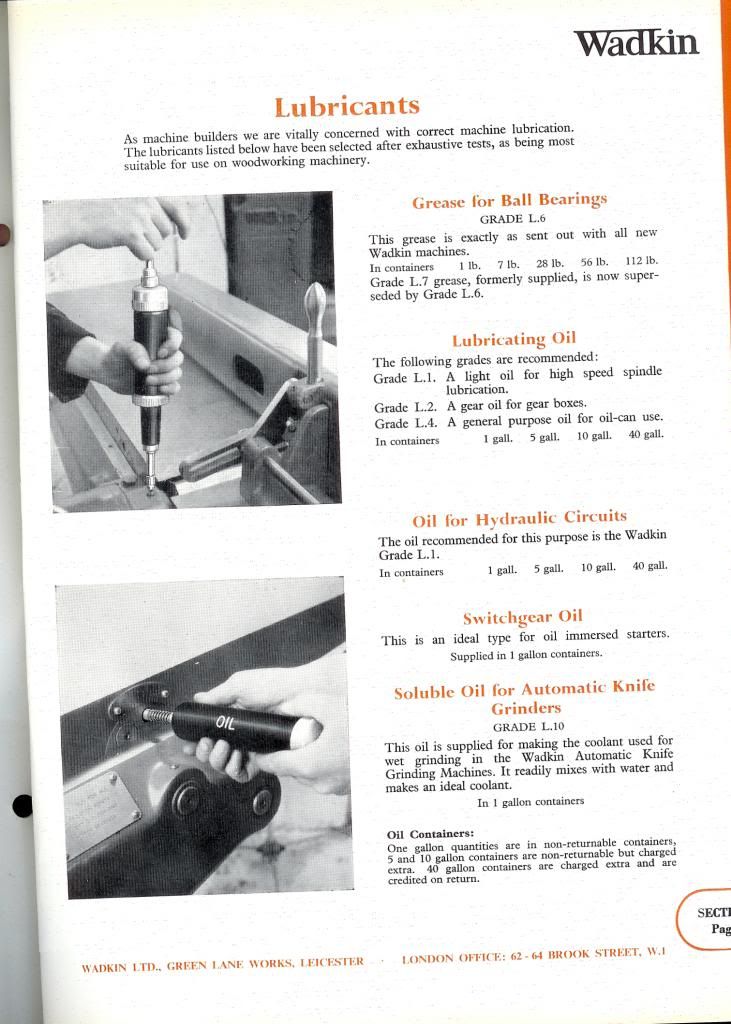

7/ Lubrication pump and tin of ball-bearing lubricant.

* As pictured below.

8/ Instruction Booklet.

* Now Camo, you do have the instruction Booklet don't you ??

And one last treat for you....

yea, I know, now I'm just showing of...lol.

Melbourne Matty.Last edited by L.S.Barker1970; 30th December 2012 at 09:43 AM. Reason: typo

-

30th December 2012, 10:54 AM #21

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Matty,

, I am now convinced you are either a time lord or warlock (I hope when you go back to get these books you are not altering the fabric of time).

, I am now convinced you are either a time lord or warlock (I hope when you go back to get these books you are not altering the fabric of time).

Cheers,

Camo

-

30th December 2012, 11:16 AM #22

-

30th December 2012, 07:31 PM #23

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- geelong

- Posts

- 125

The motor in this EQ is not by the familiar BTH (British Thomson Houston) but by LDC (Lancashire Dynamo and Crypto). Fantastic name. Were they electrical engineers and codebreakers?

Switchgear by Brookhirst Igranic;1959-1970 amalgamation of Brookhirst;the familiar;and Igranic an old English electrical firm.

Cheers

Tony

-

31st December 2012, 11:55 AM #24

Hi Tony,

I was watching that Wadkin you have, as well.

Nice machine ,and I am looking forward to seeing it's restoration.

I have a thorough understanding of what you will be doing to clean this beauty up because I bought a Wadkin 10AGS table saw of the same ebay vendor in September 2011 . It had been kept in a shipping container which had a leak, probably the same container as your machine. and any part not painted was rusty, just surface rust, with the cast top ,which was the most rusted,looking like yours.

We pulled it to pieces and put it back together and it came up sparkling .

Thanks to Matty [ LS Barker 1970] for helping me out with some nice pictures from his Wadkin brochure section of his collection, as well

I have a bit of time ATM so will try to get some pictures up in a thread of the Table saw.

Rob.

-

4th January 2013, 09:08 AM #25

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- geelong

- Posts

- 125

EQ Top Bearing

EQ Top Bearing

Received my reply from Daltons for the top bearing which is in stock

165 English Pounds

65 English Pounds DHL Delivery = 3 days

It is an angular contact 7311 bearing with Bakelite cage.

I have found a very capable local bearing chap and we are exploring alternatives.

The bottom bearing is not angular just a standard deep groove ;for those interested.

Cheers

Tony

-

4th January 2013, 10:16 AM #26

Tony, just read your post and thought better chase that up and rang my friend at CBC, he's off till the 14th....

Melbourne Matty.

-

9th January 2013, 01:10 PM #27

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- geelong

- Posts

- 125

EQ tabletop restoration

EQ tabletop restoration

The well rusted cast iron table responded to some TLC

1 Scraping of heavy deposits

2 Belt sanding of heavy deposits with worn out 40 grit belt

3 Hand sand with medium glass paper of dark spots

4 Random orbit sand with medium disk of whole top.

5 Hand sand with fine paper of dark spots

6 Random orbit whole top with fine disk

7 Hand sand (in block)240 paper in direction of table slots only

8 Wipe off and apply Topsaver; a useful product from Carrolls Woodcraft supplies.

The solitary removable ring responded to WD40 soak and gentle use of hide faced hammer.

Last remaining major dilemma is removal of outer race of angular contact bearing; there is no access for hammer or drift so will have to use a thermal technique= heat and ice

Will report back

Cheers

Tony

-

9th January 2013, 03:29 PM #28

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Great work Tony

,

,

If it is any consolation it still took me several goes to get the removable ring out (it had absolutely no rust and plenty of oil, but they are tight buggers, and I kept lifting it slightly unevenly and having to tap it back down ).

).

Love the first photo (I wonder where they store the fences and spare cutter blocks .

.

Cheers,

Camo

-

14th January 2013, 10:09 AM #29

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- geelong

- Posts

- 125

Bearing Replacement

Bearing Replacement

Purchased a new top bearing locally $371 ;bird in the hand.(The Wadkin price is very good actually ;this worked out about the same with the bearing in my hand. My supplier explained that this bearing is usually sold as a matched pair.)

Got good advice on how to remove outer race from housing=run a heavy bead of weld right round the ball track in the outer race.

I was a little dubious but broke out the Lincoln and gave it a try.(Removed felt ring with sharp knife to avoid burning it)

On cooling the bearing race fell out of the retainer;about 2mm shrinkage diametrically. Stunning!

New bearing will be installed soon,will report back.

Cheers

Tony

-

18th January 2013, 10:56 PM #30

Holy Moly that is nice work

That saw is nicer than a PK as i thought it might be. The under carage is like a Robinson ET.

Hats of SIR.

jack

English machinesAll tools can be used as hammers

Similar Threads

-

Wadkin Morticer

By S Hayward in forum HAND TOOLS - POWEREDReplies: 2Last Post: 10th July 2020, 05:43 PM -

Wadkin RAS

By pmcgee in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 1Last Post: 5th October 2012, 09:52 PM -

wadkin thicknesser

By Chipbreaker in forum GENERAL & SMALL MACHINERYReplies: 1Last Post: 27th August 2011, 10:01 AM -

Wadkin RU 15 footings

By HSS in forum WOODTURNING - GENERALReplies: 27Last Post: 15th March 2011, 04:11 AM

Likes:

Likes:

Reply With Quote

Reply With Quote