Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 71 of 71

Thread: wadkins's bench top planer

-

8th September 2012, 12:05 PM #61

New Member

New Member

- Join Date

- Jul 2012

- Location

- Barrie, ON, Canada

- Posts

- 7

Damn Jack... This must be the 12th time I've looked at those latest pics, and I just noticed that you have that pallet jack maxed out....

Now, I've never had something as heavy as a RM on one of those, but I'd be damned if I'd tempt the fates with the possibility of that tipping over.

You're a braver man than I....

Oh... and count me in for a calendar

-

8th September 2012 12:05 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th September 2012, 01:12 PM #62

J

I used the pump cart to alien the ways instead of the chain fall. Much more fine is the control of the pump cart than the chain fall. Once it was aliened i used the chain fall and lowered the jack. I was not rolling it around so it way stable. Had to do it alone and did not have any help at the time.

did some work on the tags. repainted the relief . I spray with rattle can(because the paint is so thin) and sand with 600 paper and a hard block. paste wax after that.

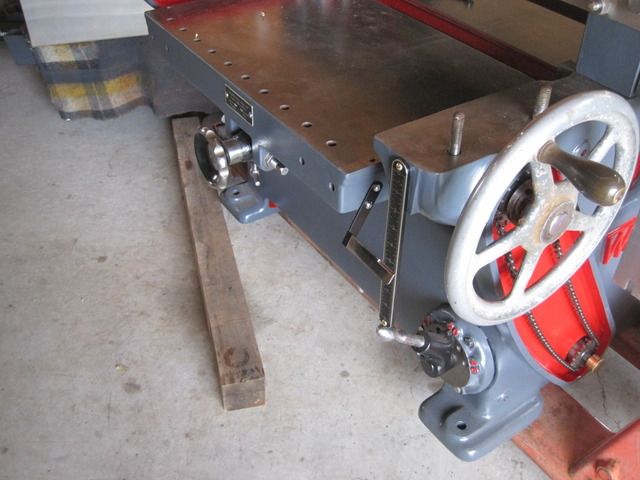

Next up is the Head casting. The RM is a platform type machine-all the parts/tables reference of the main frame . In order to get the tables on the head casting and rollers have to be on/in .

steel bar 1/2" thick tie the top heads cast together and act as limiters and a place to clamp pressure plate for the moulding function.

pressure bars

the roller and bars have rods that pass through the casting for the the spring tension. and all have jam bolts and nut to adjust the height in relation the the cuter block.

next postAll tools can be used as hammers

-

8th September 2012, 01:15 PM #63

the bearing are plain with oilier on top.

spring load adjustment. Need to find or make a few wing nuts

its getting harder to move it again.

jack

English machinesAll tools can be used as hammers

-

8th September 2012, 03:47 PM #64

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Inspiration or Frustration

Inspiration or Frustration

Hey Jack,

Every time I look at your restorations it is inspiring and frustrating at the same time. Your attention to detail is extraordinary. I know I could never do a restoration to that standard (that's the frustration), but when I tell myself, no one will ever see that part its hidden (I can go back to one of your posts and be inspired to take the time to try and do it right).

Your restoration is looking awesome, keep the pictures comming and plenty of tips on how you do it (that's the best part for me).

Cheers,

Camoz

-

14th September 2012, 11:39 AM #65

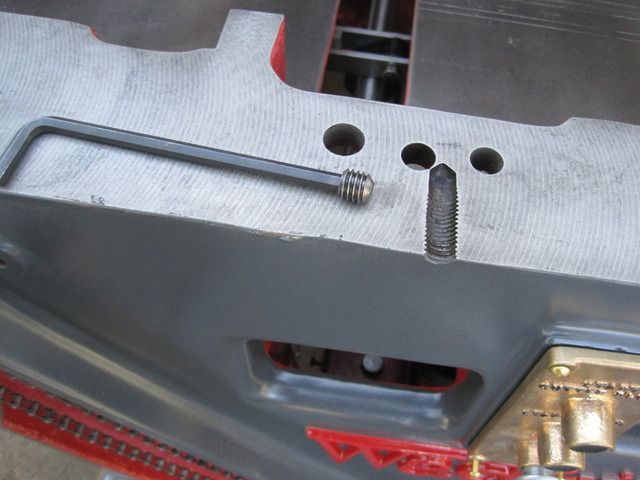

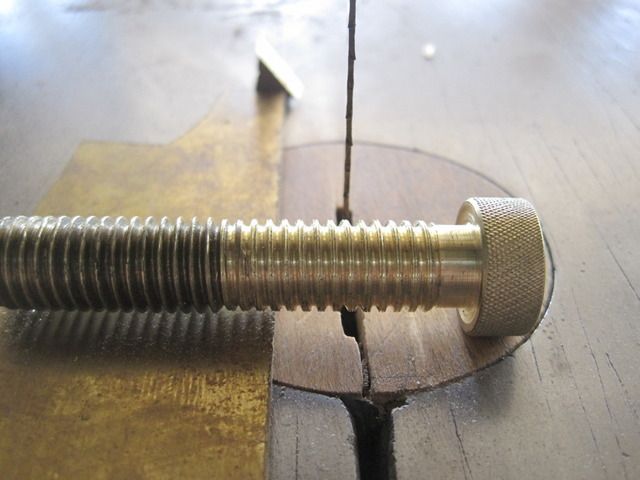

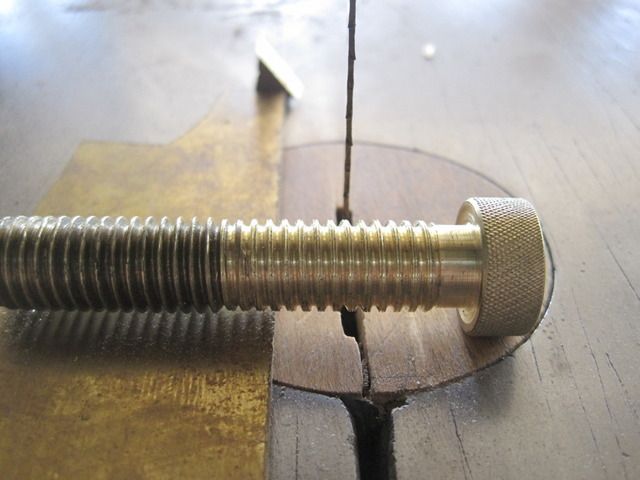

you can see on the face of the main casting that there a 4 small bosses that are taped for 1/2" bolts(one at each corner) . These where used to hold the frame while milling. I just don't like a machine that has taped holes that are not filled in but i did not want to change or grind them off or fill them in with filler and paint.

Now i could have just got some nice bolts and be done with it, but then someone may say what are those for? I would like my answer to be Looks and I made them.

photo essay

Brass bolt to work

jack

English machinesAll tools can be used as hammers

-

14th September 2012, 11:40 AM #66

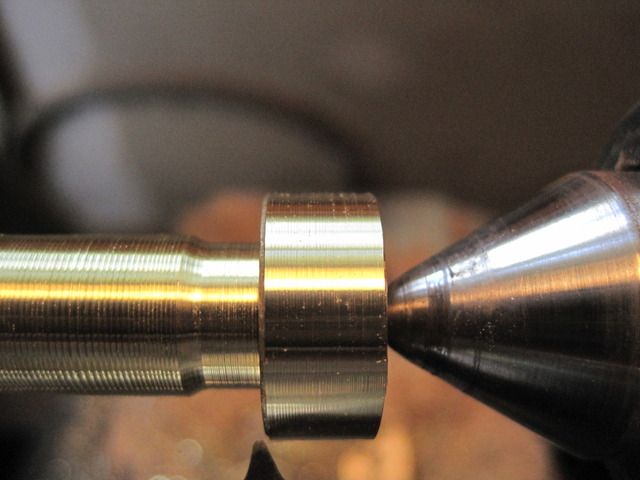

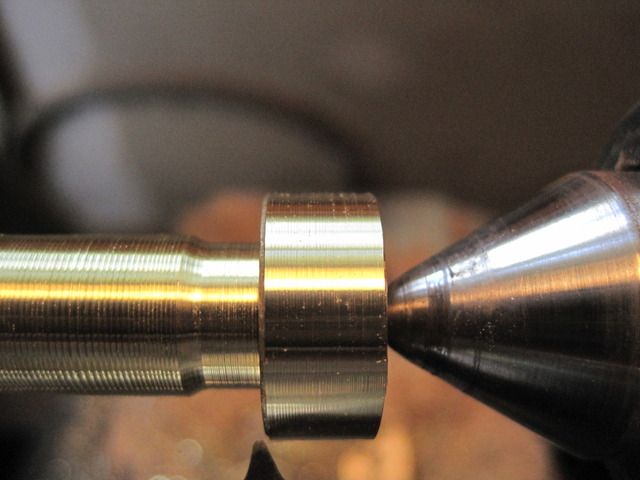

There is an oil hole on the main casting that you can drop oil on the chain for the hand crank. the cap was broken and i did not want dust to get in side so i had to make a cap.

the broken cap looks like it was a flip up affair and not what i would call up to a "jackified" Wadkin

Well that little tin POS was not going to do so out came the brass. I had some old cabinet hardware with ball plungers and decided to use a detent for the oilier cap. I took the ball and spring out and cut the part away to turn it round on the lathe for a press fit in brass plate.

all i did was make a bolt mandrel to turn it to a drill bit size and with a small shoulder I pressed it in my bench vice.

After the detent was made I drilled some 1/4" brass plate and pressed it in.

The finished jackified cap.

jack

English machinesAll tools can be used as hammers

-

17th September 2012, 12:35 PM #67

you can see on the face of the main casting that there a 4 small bosses that are taped for 1/2" bolts(one at each corner) . These where used to hold the frame while milling. I just don't like a machine that has taped holes that are not filled in but i did not want to change or grind them off or fill them in with filler and paint.

Now i could have just got some nice bolts and be done with it, but then someone may say what are those for? I would like my answer to be Looks and I made them.

photo essay

Brass bolt to work

jack

English machinesAll tools can be used as hammers

-

17th September 2012, 12:37 PM #68

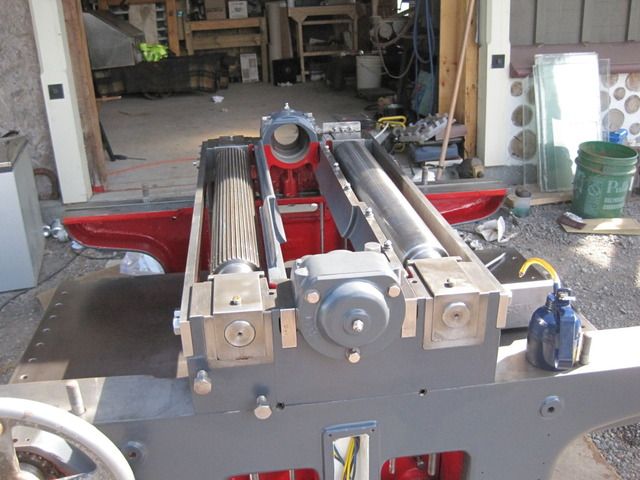

The bed roller had open bearings in the blocks that sit on top the plunger of the bed roller adjustment. and it did not look like they ever had any service. The grease was as hard a stone so i replace them with rubber seals. there was play in a few so i spent the $100 to replace them. its very import to the cut that the bed rollers have no play and that the roller are round(i had the roller turned and the pitting remove in an early post so it was time to put them in. I pressed them in the block and used a socket to drive the inner race on the roller.

these are the bed roller height adjusters that sit in the the quick change roller cams for the planer bed. this is a great feature to have in a planer as you can set them high for ruff stock or drop them down for a fine finish all with just a turn on one knob. not many planers with this in 1941.

jack

English machinesAll tools can be used as hammers

-

17th September 2012, 12:40 PM #69

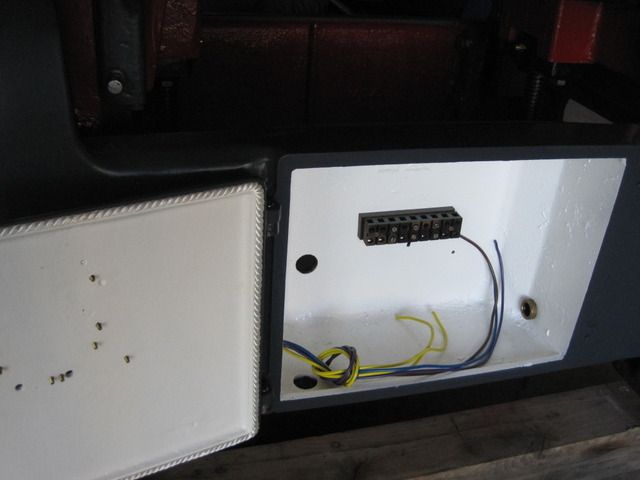

Just some pics and i will post details later.

got the wadkin Tag on ebay UK for $5

there are lots of tags on this baby and i still have 4 more to do. Of all the tags i have seen i think the wadkin are very nice looking

new rope seal on the motor control box.

look this one was made in the Earth factory

time to work the gear box side

found this pic today of what the RM looked like when Dave found it last Oct. The guy was asking $1000.

I am so glade the next ones are in better shape but the RM does not show up very offten.

so far

jack

English machinesAll tools can be used as hammers

-

17th September 2012, 09:23 PM #70

Jack, what can I say, the masterpiece that is Wadkin is coming together, who would not want such a beautiful pice of equipment like that in their shop ?

Once again Jack you set the bench mark for these restorations, and make a well deserved legendary status for you self and your skills, leaving us all amazed and opened eyed.

Thank you for taking us on your Wadkin rebuild journey.

I don't think it can get any better than this, can it ? !!

Melbourne Matty.

-

17th September 2012, 10:53 PM #71

Matty

This one is killing me. I keep telling myself that its to large to Jackifie. Yet i move forward and more gets done. I am about 1/2 finished in that last pic but the main is done. I am at the point where i think i will do/make it . I got the gear box hanging from the chain hoist over a tub so i can clean the sludge out with varsol. everything is just so big that doing a small thing like turning something over is a big deal.

One has to believe in the machine and of course them self to take on a project like this. Its comments like yours that give me the energy to keep going/moving on. I have worked this one on the side while working a big job in the shop and i will be happy when it is finished. I keep tell myself its a dream. The dream of the Wadkin Temple. Will i every be done? I hope not.

jack

English machinesAll tools can be used as hammers

Similar Threads

-

Convert electric planer to statİonary table planer

By nezih ahmet in forum HAND TOOLS - POWEREDReplies: 7Last Post: 6th June 2011, 12:36 AM -

Planer blades for Wolf Planer

By viiking in forum HAND TOOLS - POWEREDReplies: 1Last Post: 16th January 2009, 10:17 AM -

Gilbro Planer/Saw bench

By woodsprite in forum TABLE SAWS & COMBINATIONSReplies: 2Last Post: 27th September 2006, 01:38 AM

Likes:

Likes:

Reply With Quote

Reply With Quote