Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 71

Thread: wadkins's bench top planer

-

3rd December 2011, 12:36 PM #16

Dave took these for me . In video 2 you see what the PO did for motors and inside the oil bath gear box. I just love the way the chain is oiled.

[ame=http://www.youtube.com/watch?v=_erQsboKZ9o]MVI_0043.AVI - YouTube[/ame]

[ame=http://www.youtube.com/watch?v=HXzx_O8xKDk&feature=related]MVI_0044.AVI - YouTube[/ame]

jack

English machinesAll tools can be used as hammers

-

3rd December 2011 12:36 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

3rd December 2011, 03:47 PM #17

Mmmmmmmmm nice.

This should work out much better than your last effort, eh?

Paul

[ame=http://www.youtube.com/watch?v=i56qUuAMvCk]home made thicknesse planer - YouTube[/ame]

-

4th December 2011, 12:13 AM #18

A 3 speed planer EH. poor intake when the chips fly

jack

English machinesAll tools can be used as hammers

-

4th December 2011, 06:32 PM #19

-

5th December 2011, 08:01 AM #20

here are some more pic that I think you will find intersting

A grown man can not pick this motor up and I don't care how big you are. that's a tall boy can of beer for scale. I found this Wadkin motor with wadkin pulley's the right size for the head on the machines. this never happens. and the good part is it was free, so I have the head motor. I also got the electrics out of Daves Wadkin RM he is changing to single phase, so I have a starter for a 15hp motor, the PO's rig was a joke.

the head is missing a bolt for the clam and some of the bolts don't look wadkin

this a wadkin bolt it has a round head

these are not but there is the same one on the there side for balance

just so you can get a sence of the size of the jointer i put a tall beer on the table

My friend Arthur or Matty may be the only one that will appreciate these next pics

the rack pinon handle is diffident from my older 16" RD its ARN with more webs. it could be use as a dating tool. so this machines is i would think after world war 2 when Britain had many aluminum foundry for the war effort.

the wadkin head tool and the canting table

jointer(planner) tables crank

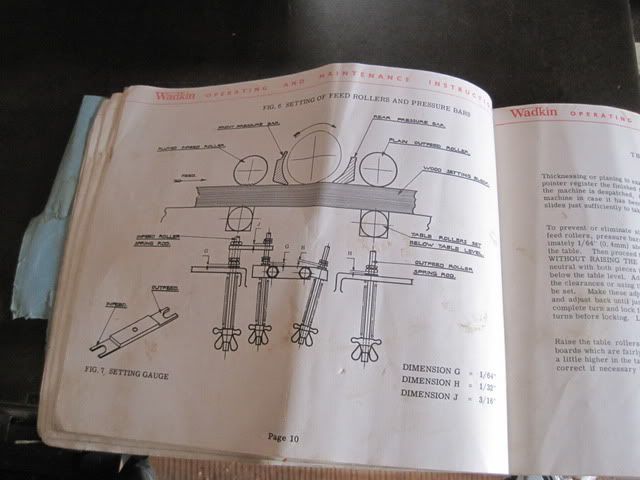

dirty papers(manual)

notice the 25 hrzs

jack

English machinesAll tools can be used as hammers

-

6th December 2011, 07:45 AM #21

" that's a tall boy can of beer for scale."

Damn ... wait 'til Lie-Nielsen catch on to this precision-beer-can-measuring-tool thing

... they'll be all brass/nickel and shiny

... and cost $79.95

-

28th December 2011, 05:21 AM #22

plate type cutterblock

plate type cutterblock

Merry Xmas boys hope ya got what you want from Santa.

with my time off until after new years i thought i would pull the head out of the Wadkin RM and work the cutter block.

There was a stud and plate bolt missing in the head and i did not like the looks of the others. The thing that got me the most was I needed a 48"cheater pipe to brake the nut free of the head,so they were way to tight.

there is an old saying about moulding knife bolts::::

if you turn nut over and it wont thread on the threads are stretched. Most are that way and so here is were i need help.

the forged steel plate type cutterblock is really a great head with its skewed knifes and is also able to take moulding knifes. I did get the tool(spanner) for the head bolts that has short handle ,so i would think 60 to 100lbs is all that is need on the nuts.

any care to comment?

question

is there a source for the studs and nuts, and what is the grade of metal/thread etc?

the ones in there now appear to be mild steel.

They BSW 5/8" by 11

The plates are tapered and so the studs lengths are long on one side and get shorter as you go across.

I hope this to be a discussion on the old plate type cutterblock and do not want it to turn into the safety of these old heads. I restore old wadkin kit and use it .

some pics

here is the block with the missing bolt as i got the machine

these nut does not look wadkin

this is a Wadkin nut with the rounded top.

the spanner

wadkin RM 26" over under

head removal

nice bearing on this one

2 RM 12 self aliening double rowed brass cage on the drive side with a 2308 SKF to the out board

hand scraped bearing retainer cap.

the head capless

jack

English machinesAll tools can be used as hammers

-

28th December 2011, 06:39 AM #23

Don't know if these are any help ...

Page 29 of this one:

http://paladinlightconstructiongroup...iles/om670.pdf

or...

http://www.imperialsupplies.com/pdf/...rqueCharts.pdf

Bolt torque specs for socket head cap screws for machine repair assembly bolt torq CNC

Bolt Torque Chart | Portland Bolt

Steel Bolt Torque Specifications Table - Engineer's Handbook

Charts

BOLTS AND TORQUE SPECS

Bolt and Screw Torque Specs - The Thelen Channel

or google "torque bolt spec chart" or similar

Paul

-

8th March 2012, 12:06 PM #24

there are two guards on a modern jointer. There is the stander pork chop/bridge and what I will call the back guard that covers the head when the fence is move over the table. Most old jointer don,t have the main and very little have a back guard.The wakin RM never had the back guard and so I made one.

A safety guard has to do 3 things to be of any use.

1 The most important is protect the operator from the cutter head.

2 be easy to adjust and not be in the way of the machines function as it was designed to preform.

3 be easy to remove for assess to the cutter head.

it can than look good if you want .

I have 26" of head to cover at any given time and I wanted to be able to adjust while the machine was running. Most back guards are attached to the fence and so I designed mine to do the same. I simply welded a simple rod and bracket that screwed in taped holes to the fence base for my guard to attach.

Because the table slide in and out to open the cutter block for moulding my guard needed this adjustment as-well.

I made it from aluminum and copper to keep it light but strong.

adjustment for sliding in and out

fully extended to 26"

fence tip 45 drgs

making progress on the motor too. but there are to many pic so see next post.

jack

English machinesAll tools can be used as hammers

-

8th March 2012, 12:08 PM #25

The motor I got for the Wadkin RM is Not a Wadkin Motor. I needed a footed motor to drive the head and This 3 phase 5 HP baby should do a fine job of it. It is most likely off an old band saw based on the bearings . It's got open deep grooved ball bearing set in the bells. One great features to these type motors is the grease bled at the bottom so you can't over grease and the old grease stays out of the motor winding. This motor should last forever for what I am using it for. They say it is wise to change the bearing when you got things apart ,but I have had good luck determining if bearing are good or not by running and looking in side. So far I have only been off once. I must have saved $2000 so far in the rebuild once I started checking the bearing in stead of just changing them because they were old. Most if not all the bearing I am talking about were open . I have never found good old sealed bearing.

the motor after a test run on power.

theses bearing looked a sound great and pressure on the shaft had no play. I cleaned the old grease out that was in general good looking . It was not hard or soapafied.

The fan end bell of the motor had a neat mesh grill to keep shaving out of the motor. It was neat but not up to what I wanted and thought it looked not all that great. It got filed away under G. I made my own at the drill press with some scrap sheet stock.more on that later.

So really all and all the rebuilding of this Motor was just maintenance and was ready to go to work.

For purely atheistic reasons I paint things at this point and like to add what i call an artistic licence. My restoration are what I think they should be and so I indulge myself. I find Machinery in it original state boring and drab and like to hot rod some things.If you like original look away

The motor finished

jack

English machinesAll tools can be used as hammers

-

8th March 2012, 06:53 PM #26

When you put that much detail into just the motor - you just know the end result is going to look awesome

Is that an enamel paint?

Thanks,

Paul McGee

-

9th March 2012, 12:22 AM #27

This one i am going to town on

This one i am going to town on

Paul

The paint is an alkyd enamel. I have been working with sheen's lately and on the motor there is semigloss for the dark grey ,the black bells are satin the bearing rings are flat with the red in high gloss. I find this adds to the dimension of the paint job.

I would like to note that I have machines that do the work of planning and jointing and so do not need to get this one up and running to earn its keep. This has giving me the time to have some fun. This one is going to be big and beautiful I hope.

jack

English machinesAll tools can be used as hammers

-

11th March 2012, 04:32 AM #28

Member

Member

- Join Date

- Feb 2011

- Location

- Ottawa, Canada

- Posts

- 55

I managed to miss this until now. That has to be one of the bigger jointers that I have ever seen. Refurbing it looks like loads of fun.

-

11th March 2012, 03:47 PM #29

That sure is a bigun'. Can't wait to see picks of it finished. Loved the work you did on the big chain mortiser.

-

11th March 2012, 06:29 PM #30

Hi Jack,

What they said. Love your work. Keep 'em coming.

Cheers

Pops

Similar Threads

-

Convert electric planer to statİonary table planer

By nezih ahmet in forum HAND TOOLS - POWEREDReplies: 7Last Post: 6th June 2011, 12:36 AM -

Planer blades for Wolf Planer

By viiking in forum HAND TOOLS - POWEREDReplies: 1Last Post: 16th January 2009, 10:17 AM -

Gilbro Planer/Saw bench

By woodsprite in forum TABLE SAWS & COMBINATIONSReplies: 2Last Post: 27th September 2006, 01:38 AM

Likes:

Likes:

Reply With Quote

Reply With Quote