Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 71

Thread: wadkins's bench top planer

-

11th March 2012, 09:15 PM #31

-

11th March 2012 09:15 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

12th March 2012, 01:21 AM #32

Matty is the man

Matty is the man

thanks everyone one for the comments they sure make a man feel good about saving these machines. And Bob I am in the west end of Ottawa and its nice to see another frost bitten Canadian on the site.

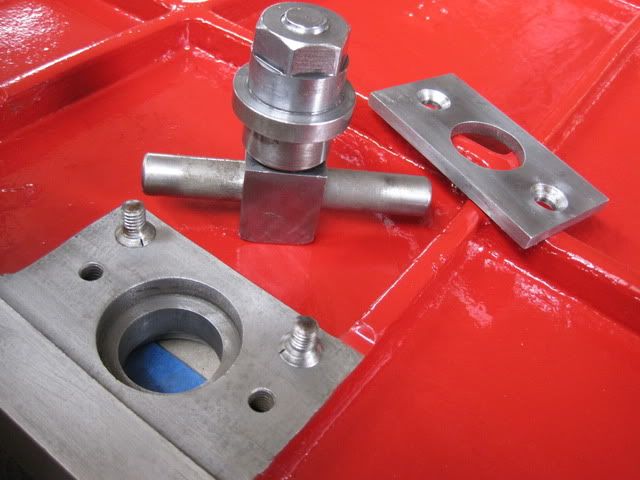

I got the head cleaned up and ready to store until i am ready to work the other parts.I wanted to clean the rust and look at the bearing any way. here are some pics of the workings of the wadkin plate/clam head

here you can see that the cutter block is tapered on the sides the jointer knifes plates/clam go.

the wadkin head has keyed jacking/ knife adjustment screws and you don't need the plates to to hold the knifes from slipping like the Oliver head. the stud hole is through the head and the stud bottom on a small rim on the top edge.

a set of Wadkin spent knifes(no life left) with the key slot at the back on the blade. only half of the knifes are useful in this design. the blade are about 1 1/2" wide when new. You are still able to get theses from wadkin.

i have found regular knifes placed in front of the key screw. this is very dangerous with this type head.

you have a 12" section for moulding knifes in the jointer head and it does not upset the straight knifes.

the hard wood side of the head is thinner than the softwood side of the head by about 5/8" this is what skews the knife.

as you all know it's all about the business end on the planer that makes them good machines and the head need new bolts and studs. you are never going to find new old stock bolts made by wadkin on a head that is 70 years old. Don't even think about it .

That is unless your Matty. Look what he found me boys. The impossible

Thanks Matty my fellow Wadkin machine Lover.With the help from my friends the Wadkin temple is getting closer to being a realty.

jack

English machinesAll tools can be used as hammers

-

12th March 2012, 04:50 AM #33

-

2nd April 2012, 12:21 AM #34

Not much to report on the rebuild,but i did find a Brooks feed motor for $30.

i started working the bed and what to most people looks bad just needs a shave. For old rusted tables I like to give them a shave.I buy my straight raisers in boxes of 100. took about an hour.

i pulled the bed rollers and checked the bearing. they were gone and because they are not to easily serviced I replaced them with rubber sealed SKF. $100.

the serrated infeed and smooth outfeed and bed rollers went to a metal lathe to bring them back in spec. I know the guy so $30 but a proshop should only charge an hours labor.

the blocks that hold the cutter head and rollers/ pressure bars are all cleaned up and the plain bearings for the rollers were in great shape. Steel in cast "ARN" with oil channels cut in the bearing like in Babbitt. there is a hole left from the hold downs spring rod that leaves a hole for the bearings oil and the ways are cut from there. should I add a piece of felt?

bearing were gone on the motor and new sealed SKF $30 bearing were instaled. it look like a rewind had be done. If you have never experienced how smooth a 3 phase motors run watch the video.

you tube

[ame=http://www.youtube.com/watch?v=UwIqo8GIemY&list=UUI6jpIs2zjN9DmVvK2ZAWXA&index=1&feature=plcp]English motor rebuild OWWM - YouTube[/ame]

jack

English machinesAll tools can be used as hammers

-

5th April 2012, 12:39 AM #35

-

5th April 2012, 11:24 AM #36

Paul

I went through about 30 razor. Pitting is the result of standing water or out door storage and the scraping with not do any thing for that. But thick condensation rust from storage in an unheated building will scrap up with not pitting.

I get the good quality razor at the pro paint shop that are thicker than most too. A box off 100 is about $15. I also keep the one i dull from cutting painter tape on areas i have masked off and use them for scraping. A tip is to keep flipping them over and over until they no longer cut.

jack

English machinesAll tools can be used as hammers

-

23rd April 2012, 11:33 PM #37

boy handle are the pits. 1 as is,2 sponged,3 jackified.

off with the tables

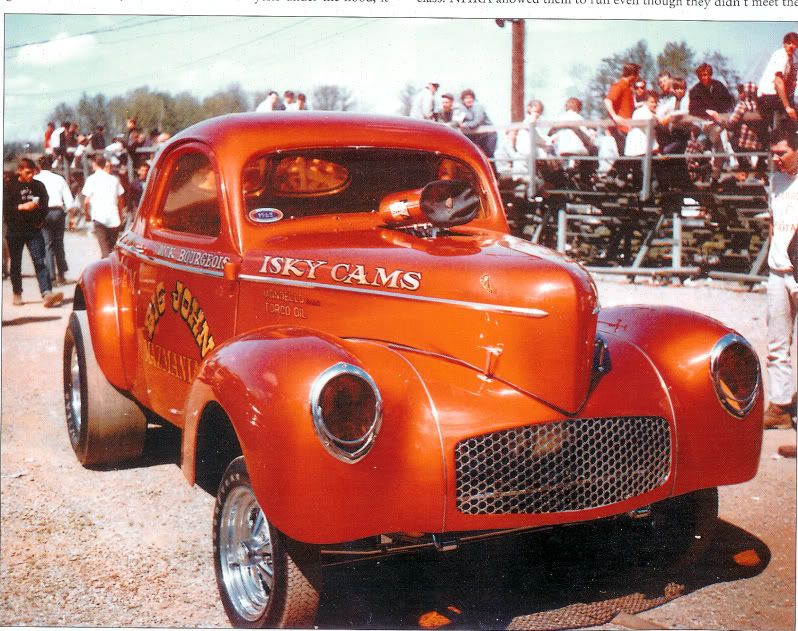

This Wadkin RM came with the special order pattern makers in feed table. What's a Pattern makers table?

When making wood pattern for the foundry sand cast forms, the patterns had to have draft. What's draft?

Draft is a small taper in the pattern forms so that it would release from the sand. So for a joiner to be a Pattern makers the front table has to tip side to side. The table will no longer be coplaner and the wood will be removed more on one side than the other.

The under side of the table has a large pivot and a thread crank. The edge on the table is milled so that when it is lowered it will go back to co planer when the two machined surfaces meet.

This thread crank sets in the table

The first time I have ever seen this in a Wadkin piece. There is nickel weld in some of the cast to fill in a void in the sand cast. A war machine from 1941 and to wasteful to replace the casting is my guess.

Next is the rise and fall ways. you can see the planed surfaces that mate the tables.

Pined to the table

When theses two surfaces meet the table is co-planer.

A gauge to read draft. So fine is the machining in this table that even the gauge is flush with the front edge so as not to upset rabbiting.

Don't let the short table foul you this is a finely tuned machine. All the ways have been scraped in.

The other half of the rise and fall and the plate for moving the table in and away from the cutter block for molding.

there are no gib plates to adjust for ware and fit to the side walls, just a hand scraped in fit. By the looks of the ways this 70 year old machine appears not to need them.could just be the size on the ways.

The out feed table should be a breeze.

jack

English machinesAll tools can be used as hammers

-

19th July 2012, 05:48 PM #38

Novice

Novice

- Join Date

- Feb 2011

- Location

- queensland

- Posts

- 13

Unbelievable

Unbelievable

G'day Jack,

Mate you're an inspirational genius, I've just got hold of an old Nuttal Lathe (about 50 year old) that's been converted for wood and I am blown away by your perfectionist restorations.

You've inspiried be to really clean it up

Have you got round to finishing the planer off? Be great to see it

All the best

Damien

Brisbane, Australia.

-

20th July 2012, 01:19 AM #39

Damien

thankyou for your comments. Its means i am on the right track.

Your lathe looks like a big bit of kit What can you tell me about the maker?

What can you tell me about the maker?

I like my Wadkin all spit shined and I do have a bit more done on the RM. Stay tuned as posts will be coming soon.All tools can be used as hammers

-

23rd July 2012, 12:36 PM #40

not much to report but I did get the rise and fall works out of the RM and I did not brake anything.

the bed roller adjustments where rusted solid and were a lot of work to get apart and clean then shine.

the bed roller adjustments where rusted solid and were a lot of work to get apart and clean then shine.

the out feed table is ready/done. One thing with the large machine is you have to let the paint cure before you handle the parts(2 weeks). I will be working on the main frame next.

For body work I start with cast grinding after a pressure wash. I like to clean the shapes up a little and get the line to flow better. some may not agree with this so look away.

jack

English machinesAll tools can be used as hammers

-

23rd July 2012, 11:07 PM #41

Novice

Novice

- Join Date

- Apr 2007

- Location

- South Hobart

- Age

- 69

- Posts

- 23

Hi guys,

I like the efforts with the Wadkin. What a stunning machine! I attach a couple of images of machines in my workshop, including a Wadkin 24" thicknesser, Wolfenden 12" planer, Barker 36" Bandsaw, Macson table saw with bottle jack rise and fall addition, and an old German bandsaw... cheers, George

-

24th July 2012, 12:59 AM #42

George

Love the rise and fall handles for the jack in rip saw. those Macon? sure look like the wadkin SO(is the rise and fall table broken). Your thicknesser is a far better machine with the 4 knife head and serrated feed rollers no to mention the 15 hp motor. The Wadkin RK is there best panel planer IMO. thanks for sharing.

jack

English machinesAll tools can be used as hammers

-

25th July 2012, 11:02 AM #43

Novice

Novice

- Join Date

- Feb 2011

- Location

- queensland

- Posts

- 13

G'day Jack

G'day Jack

About the Nuttal Lathe, apparently Nuttal machinery were made in England and my Lathe was the type used to make bombs. From what the previos owner could tell me, the factory was bombed by the Germans, so they shifted the factoy out to Adelaide in Australia. I has been modified for wood and has been stepped up off the bed for greater clearance. The previos owner was Veet, a really nice bloke who turns big drums. oshoveetwood.com spent the day with me showing me how to use it.

After seeing you beautiful work Jack, you've inspiried me to go to town on the lathe and spruce it up a bit.

I have had a look on the net for information on the Nuttal, but can't find much at all

-

25th July 2012, 11:43 AM #44

-

25th July 2012, 03:31 PM #45

The metalwork guys were keeping this to themselves:

https://www.woodworkforums.com/f65/in...-lathe-150000/

and there's: Australian made machine tools - Page 4

(that thread starts here: http://www.practicalmachinist.com/vb...e-tools-76577/)

Cheers,

Paul

Similar Threads

-

Convert electric planer to statİonary table planer

By nezih ahmet in forum HAND TOOLS - POWEREDReplies: 7Last Post: 6th June 2011, 12:36 AM -

Planer blades for Wolf Planer

By viiking in forum HAND TOOLS - POWEREDReplies: 1Last Post: 16th January 2009, 10:17 AM -

Gilbro Planer/Saw bench

By woodsprite in forum TABLE SAWS & COMBINATIONSReplies: 2Last Post: 27th September 2006, 01:38 AM

Likes:

Likes:

Reply With Quote

Reply With Quote