Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 46 to 60 of 71

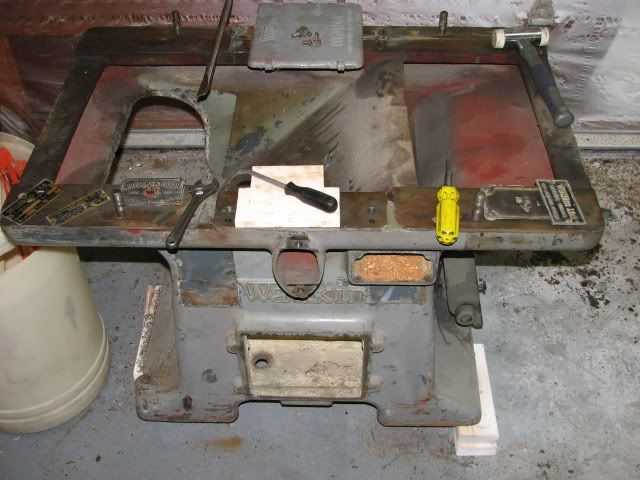

Thread: wadkins's bench top planer

-

26th July 2012, 10:42 AM #46

-

26th July 2012 10:42 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

26th July 2012, 11:33 AM #47

Novice

Novice

- Join Date

- Feb 2011

- Location

- queensland

- Posts

- 13

Thanks very much guys, will have a look at these sites and see what I can dig up

-

8th August 2012, 06:34 AM #48

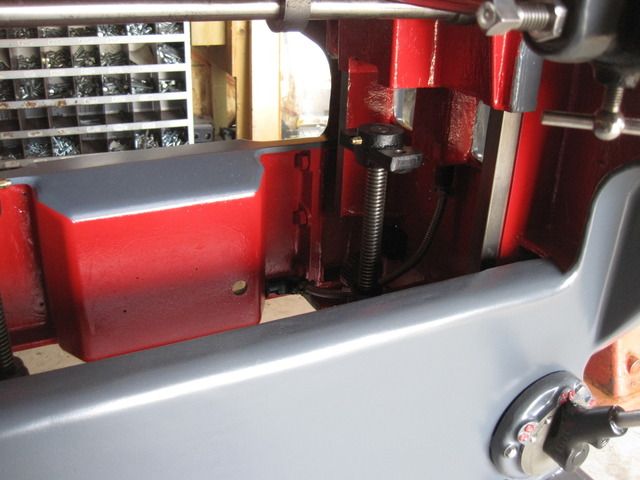

From what I can tell Wadkin cleaned the castings from the yard and sprayed red oxide primer over the entire cast. They then did the milling(this is clear as no one would have taped off the milled surfaces and then painted. This would have been very easy to do at the beginning and would have protected the casting from the wet London England weather.. Now some parts got red gloss paint on top of that particularly the oil bath gears and oil tanks. It is funny that even the bronzes gears got red paint. White us always used in the interior of electrical built in switch gear as you noted to see better. I have really only seen this on the larger tools that where to heavy to work and would have need chain lifts during the batch run building type model. It looks like the machines were finished after that were put together with lead fillers sprayed wadkin dark gray and in some cases hand painted.

Here is a Wadkin 16" RD with the interior and electric box in originality condition.

The base for the RM at a guess striped down comes in at 800 lbs. This is about as light as it will get and so time to flip it over to paint the bottom. What I found is that large machine rust from the bottom up because that's where the moisture is and the bottom has not been protected with paint. This machine will have wood pads added to the bottom so a pallet truck can move it around so the paint will stay and not be scraped off the feet and start the rust going again.

After I pressure washed and degreasing the machine I found that much of the original wadkin filler was blasting off. I did not what to take any chances that the new paint would not have a good base. It turns out the rust had gotten under the filler in spots and have undermined its adhesion. Wadkin OEM finish is a smooth look and all sand casting marks were gone over with lead filler. It is always best to preserve this as bondo is just not the same. I endded up using bondo(the gold stuff) to make up the missing spots about 80% of the base. so with a combination of angle grinder and filler the base was prepped. the Wadkin cast name in front was in very bad shape with missing parts to the letters so with a few hours and a dremel I reworked the to be red wadkin name. Parts that were missing have/had be built up with epoxy JB filler.A lot of work.

3 more coats and on to the red paint inside this time with a brush.

jack

English machinesAll tools can be used as hammers

-

9th August 2012, 07:20 PM #49

Keep up the amazing work mate. Love the tips as you go.

-

19th August 2012, 12:55 PM #50

seeing the light

seeing the light

The Wadkin letters that are not painted with the cast laying down are hard. All my wadkin's have sprayed high gloss red letters . I could just hand painted the red ,but it just no the same finish. so I cheated again with taping them off. The trick is to use lots of little pieces of tape to get the lines. I will not use anything but blue tape. you can learn the hard way to if you wish.

The DTM(direct to metal )paint that i use for the Wadkin gray has to cure for over a week before you can do this.

OK the main is ready to put the Rise and fall back in. The next time you are going to see how this thing is built. you are going to brown your trousers.

just a few hits with an artist brush and Wadkin would be proud.

jack

English machinesAll tools can be used as hammers

-

19th August 2012, 03:42 PM #51

Wow !

Wow !

I have already wet my self I'm that excited and your telling me there's more ??

Your in a league of your own jack, I mean who around the world is doing this standard of restoration work on old machine's ?

Not many !!

Lovin every post Jack, Thanks for showing, and keep it coming !!

Melbourne Matty.

-

20th August 2012, 07:23 AM #52

thanks Matty you comments are always the best. I do love doing it.

started to rain here so i had to pack things up . I did get the feed control set into the machine.

I do like the the hand painted cut in number better than the taped off ones. you can't have been drinking the night before though.

jack

English machinesAll tools can be used as hammers

-

20th August 2012, 12:51 PM #53

The rain stopped and I was able it get the thread lift for the table in on one side.

the Rm has many plain beaings steel on steel or in cast that are greased with grease cups, these have held up great-infact beter than the ball bearing in there . They are all slow moving parts thought.

here is one side of the table lift.

inside the frame large cast brackets(2.5" thick) set to post out from the frame so that the threads of the table rise and fall can be completely encased from dust under the table. there is a lot of work in pattern making and engineering to do this.

and most planers have there thread lift at the sides.

its starts with the steel sleeve bearing set into the casting bore, you can see the channel cut into interior so grease spreads over the shaft.

this threaded taper pin locks it in and lines up the grease holes in the casting.

next are the thrust bearing that take the load of the Table. there are no way to get at these open bearings other than taking the tables out. the old grease was hardened wax and so i decided to use a synthetic grease EP grade 1.5 for them this time.

see next postAll tools can be used as hammers

-

20th August 2012, 12:52 PM #54

a brass grease cap threads into the casting to grease the bearing. I love theses things you fill the cap with grease and give it a turn every 6 months

the thrust bearing is taper pined to the thread lift.

jack

English machinesAll tools can be used as hammers

-

20th August 2012, 09:07 PM #55

Two questions Jack.

1. How does the feed-speed adjustment work?

2. When will we see the massive new classic book "Forsberg on Wadkin" ?

Amazing again.

Paul.

-

20th August 2012, 10:00 PM #56

Paul

On the end of that thread is a large bronzes gear and a shaft runs across the two to a chain drive up front with hand crank. it will all come clear. much easy to show than describe.

I will be doing it next. I have to do a fair bit before i can put the table back in. I am glade I got the main frame done. this is the first i have been able to put some of it back together sense I got the machine last November. it will take a year to finish this beast, and that is with all the help from my friends at home and down under.

Would you buy a copy of the book? Matty would need one for his archive

Thanks Paul your posts are fun to read and i love em.

jack

English machinesAll tools can be used as hammers

-

20th August 2012, 10:11 PM #57

-

20th August 2012, 10:19 PM #58

All tools can be used as hammers

All tools can be used as hammers

-

21st August 2012, 04:03 PM #59

-

8th September 2012, 11:47 AM #60

why wadkin

why wadkin

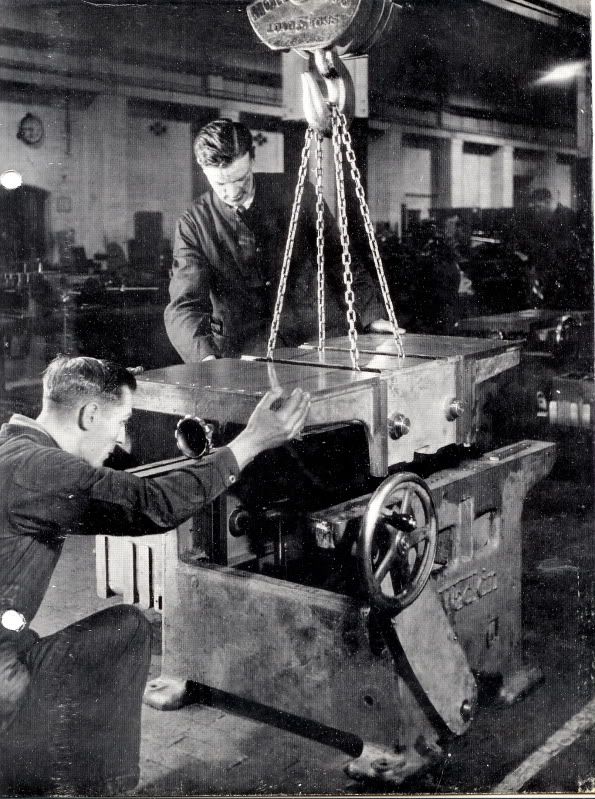

Why Wadkin?

This image has always been a Favorite in the wadkin catalogs for me. Too see the men putting the RM together back in the early 50s is a real treat. A time when men made machines. I believe that the machines made by theses craftsman's were to replace hand tool work and this generation is the closest to come to woodworking hand tool replacement there is in terms of woodwork hand tool quality. Today its all about technical gizmos that change how you build. 32mm modern cabinets construction and the machines made for them are so far removed from woodworking

that the machines are useless for any other type of work. there is clearly a movement to Hand tool Quality in the last 10 to 15 years with all the new hand tool makers. paying $600 for good hand plane is by no means the upper crust in the price range . Any here who collect old hand tools for there better stander have seen the price skyrocket.Yet many of these same people do not see POWER MACHINERY in the same terms. I on there other hand do. where else can you get a pattern shop machine for the price of a battery for your cordless drill.

I had pics of the rise and fall and lost them on my camera. but I did get it together very good. What I did learn is that I should have marked the gears/tooth so that they could have had the threads timed.

the threads are uncased in the table and this keeps the saw dust out of the rise and fall threads. To improve the oiling I add oil socked paper towels at the top of the in closed in boxes.

i finished the letters.

jack

English machinesAll tools can be used as hammers

Similar Threads

-

Convert electric planer to statİonary table planer

By nezih ahmet in forum HAND TOOLS - POWEREDReplies: 7Last Post: 6th June 2011, 12:36 AM -

Planer blades for Wolf Planer

By viiking in forum HAND TOOLS - POWEREDReplies: 1Last Post: 16th January 2009, 10:17 AM -

Gilbro Planer/Saw bench

By woodsprite in forum TABLE SAWS & COMBINATIONSReplies: 2Last Post: 27th September 2006, 01:38 AM

Likes:

Likes:

Reply With Quote

Reply With Quote