Needs Pictures: 0

Needs Pictures: 0

Results 1,651 to 1,665 of 3347

-

1st May 2010, 12:32 AM #1651

Four more snaps...

1. Sanded board. Sanding block on RH edge of photo: the rounded edges helped quite a bit

2. Borer holes..., or where the alex slipped more than once... The two holes towards the centre of the photo are filled with sanding dust, and are a lot deeper than they appear here - well past the centre of the board

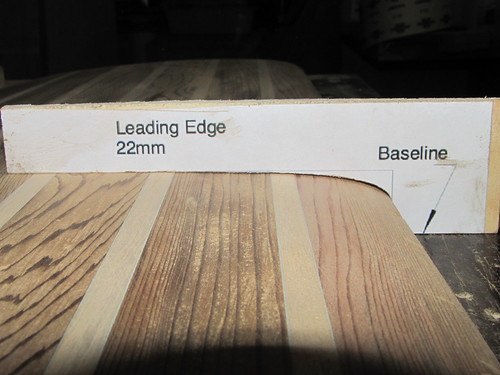

3. "Top" view of gap between template and board: probably causef the router swinging out of alignment vertically while in transit around the steep part of the LE; and the fact that the workbench's top wasn't flat. Not terribly surprising, given the heavy objects sitting on it (a mill, a computer monitor, plus a couple of other power-tools)

4. View of template/board gap as seen from around the front. And as you can see, there are still router-bit channels that haven't been fully planed out: so there really is something amiss here

Follow this link past the lovely flowers, the sweetly-smelling clover, the fwuffy bunny wabbits and the savage guard dog to see these and all sorts of other goodies in my Flickr account

I'm not particularly sure that the big router is going to be much of an improvement; it is certainly going to be a lot more difficult to wield. And this time it will go right though the board and probably the bench too, if I slip, although one reason for the larger router being used is that it will be less likely to fall off the rather-too-wide guides (for the smaller router). If I find it too heavy. I'll bulk out the inner faces of the guides by super-gluing some thick balsa scrap onto them.

-

1st May 2010 12:32 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

1st May 2010, 10:17 AM #1652

You'll lose those holes easily enough Alex. Consider filling them with black so your foil has beauty spots

The other thing to remember is that you're building a foil for a small boat, not an aeroplane wing - it's neither structural nor is the shape ultra critical (though the closer to the template the better - you won't notice it on the water, maybe Mik would).

It's looking good mate.

Richard

-

1st May 2010, 10:19 AM #1653

-

1st May 2010, 12:56 PM #1654

-

1st May 2010, 04:00 PM #1655

Hmm... Not going to use the big router on the folis - I can't control it sufficiently for such a (relatively) delicate operation. And this time, I'm going to bit the bullet and screw the (half) blank down onto the bench, once I've had a cup of tea and recovered from getting the router bit set (the width of the bit that I decided to use - 0.25 " - painted me into a corner with respect to the length of said bit, and as a result ran out of router adjustment before I got the bit end anywhere near the surface of the board (this time and last time). Which meant a frustrating amount of fiddling to get the bit set at the right height/depth/whatever. Probably better than tinkering with the guide and guide's slot heights at this stage, though ;).

-

1st May 2010, 04:10 PM #1656

Meanwhile, Charlie Bruin, after being inspired by your foil, spent a weekend talking his Grandad into parting with that old plane in the back of the cupboard, spent another afternoon breaking the blade free of the rust so he can sharpen it, glued together a heap of staves using very slow set epoxy, shaped his foil and now has six coats of varnish on it

Richard

just funning, I know that the journey is nine tenths of the experience for you

-

1st May 2010, 05:51 PM #1657

Hi Richard,

Ah well, them's the breaks - lucky I'm not in a race...

I've routered the channels in the other side of the blank, and started planing the thing down. Decided that the plane were getting blunt, so whipped out the blades to sharpen them. BUT...a bit earlier today when I was fossicking for 6 mm balsa scrap to bulk up the router guide sides, I found all four coarse oil stones (one a 3-sided Arkansas) plus a small diamond plate in a box of stuff from the former study. So of course I've been hard at it flattening the backs of the Nos. 4 & 7 plane blades - and heavy going it is, too. The No. 7 blade has several fairly deep scores on the blade back (not put there by me ;) right on and extending back from the cutting edge for about 8 mm, and they have proved very hard to shift. I've got as far as I intend to for the moment, or I'll be at it another week. Or a day, anyway. And I've limited the flatness to as close to the blade-edges as I think safe, i.e., I'm not flattening the entire backs (that way lies madness, twitch twitch).

So Charles will be sailing long before I've even got my paint on (let alone sail stitched) - as I say, good thing I'm not in it to set any building speed records. Although I'm not eager to beat BitingMidge's Eureka record either - sorry, Peter :).

Better get back to it. Well, in a bit, anyway ;). Maye I'll be lazy and choose some speedboat photos to put up...

-

1st May 2010, 06:04 PM #1658

Time spent fettling sharp edged tools is never wasted, they make the whole experience sooooo much more enjoyable, not to mention possible (guess how I know this

)

)

As for me, I've just finished the weekly hunt and once I've salted the dinosaur steaks, I have to do the washing (three loads), change the cat's tray, do the birds and ignore the lawn. Seeing it's 4:30 now, I'm guessing I won't do anything on the boat, let alone do the bike (she needs a good clean, new cassette, new chain, new tyre, new tubes, seat waxed, etc).

Richard

-

1st May 2010, 11:12 PM #1659

Hi Richard,

Sounds as though you bike is being rebuilt .Not putting in a new frame, handlebars and wheels at the same time, are you?

.Not putting in a new frame, handlebars and wheels at the same time, are you?

Regarding the plane-fettling, it's got to the frustrating stage again - the coarse oil stones aren't removing as much metal as I suspect the water 300-grit stone range would - and it is that grade w/s that I don't have. Even after half and hour rubbing away at the back of the plane blade, there were still obvious deep scores (from the initial milling of the blade, plus other odd-looking scores). I decided that I was still on a hiding to nuffin' with the blade backs, so moved on up the w/s series (although it is annoying to get to the 6000 or 800 grit and see dark lines in the mirror surface. Oh well).

Got the second LE done this evening, using No. 7 and block plane, plus sanding block. The curve is a lot better than the one on the other side this time. Today's plane's cutting has improved a bit over yesterday's, although not as markedly as the sudden leap in improvement in the No. 4, post new sharpening technique (well, a sharpening technique . The No. 7 is more responsive to small turns of the wheel, so I guess that's an improvement in itself.

. The No. 7 is more responsive to small turns of the wheel, so I guess that's an improvement in itself.

I have, however, one final trick up my sleeve before reaching for the glass cloth and resin: the board with is 282 mm, not 2280, and I may be able to claw back some meat in the LE by carefully removing 2 mm from said LE using the Triton. I'll need to set the fence up carefully with a straight(!) extension, as the harwood TE is now considerably shorter than the LE, and the TE also now sports two "dangerous" curves, one at either end .

.

Tomorrow is finishing off the sharpening of the No. 4 blade after its partially successful back-flattening this arvo, then getting stuck into TE No. 2...

Hope you got to the bike.

Cheers,

Alex.

-

2nd May 2010, 12:30 AM #1660

-

2nd May 2010, 12:52 AM #1661

Didn't get to the bike. She got a new crankset a week ago, this weekend it's a new chain and cassette ... after removing all the filth that regular commuting layers onto a bike. The tyres are getting new tubes because these modern tubes pack up after 12 months (or is it just one summer's heat) and I've just had a flat that wasn't from a foreign object - hole inside of the tube, against the rim tape (not near a nipple hole), in a tube that hasn't been disturbed in 3,000 km so it weren't no foreign object that did it ... besides, I went through all this last summer as well so it's new tubes front and rear and a new one in the tool bag. Cheap insurance.

As for rebuilding the bike, well ... I bought her as a new frame, old stock but never built up. Then I built the bike. Built the wheels myself (and they're still true) - Ultegra hubs to Velocity Deep V rims - dem's bullet proof mate. Did everything but fit the headstem bearings - the shop that sold me the bearings needed the frame to make sure we got the right bits and seeing they had the tool to hand, fitted them for nix while I paid for the bits. The saddle is a Brooks leather B17, my standard saddle on all my bikes now. The bars are oddly shaped things I imported from America (the Nitto Noodle). The gearing is a mix of mtb and road bits to get the gearing range I need - Ultegra and DeoreLX shifters, cranks and cassette - top gear is 52 front to 11 rear while my granny is a 26 front to a 32 rear (I can climb the sides of buildings with that gearing, and I need it on my commute home). Rack fitted coz I don't like back packs. Although the shifters/brakes are modern Ultegra, the brakes themselves are grey Shimano600 jobbies from the 90's that work just as well as the new stuff (a little heavier) but the grey looks waaaayyyy nicer than the modern silver.

The frame, although new, was old stock from a shop, so had a few chips in the paint sooooo, the day I got it, I carried it into my local chemist. The lady behind the counter gave me 'a look' when she saw the frame, a look that then changed to horror when I asked for nail polish, a look that then morphed to delight when I told her I wanted the polish to paint the chips in the frame. She then spent a happy ten minutes carefully matching nail polish colours to my bike

She's a unique bike - you can't buy anything like her in the shops. After her third neck and much other fiddling, she now fits me nicely (though the frame is a cm oversized). I can and have ridden her all day ... and now she's a commuting hack ... while my other bikes hang on the wall gathering dust.

Attachment 136038

The only change from this photo is she now has the HollowtechII cranks (coz the old octalink were rubbish and kept working loose).

Richard

I reckon I might have out-Alex'd Alex with this post

-

2nd May 2010, 01:49 AM #1662

Daddles

Are you one of those crazies that rides up Flaggy Hill ??!!!

If so, I am in awe !!

How about Oakridge Rd to Chandlers Hill ?

And you won't have out-Alex'd Alex unless your "cassette" is by Eurovox.

I, on the other hand, have a bicycle. Can't remember the brand, but it has pedals & spokes & stuff.

And a front disc brake that even works in the rain! How good is that !!

Alex

Your leading edge isn't an error...

An error is what I've done with mine - started with 28mm staves & finished with 19mm blanks...

Watch out when screwing them down for shaping. I worked out the twist in

my finished board was due to being screwed to an not absolutely square &

flat work-top. The template follows the work-top, not the board...

AJ

-

2nd May 2010, 10:09 AM #1663

Fond-ish memories of my old 3-speed Raleigh - from when they were still "made in England". Weighed a ton but got me to school and uni and back without much bother year after year. Mind you, uni was a flat ride, and the school run was a gentle gradient.

Rode Dad's old Sunbeam complete with chain-cover/oil bath up to the Waite occasionally during a later period when doing the Ag degree there - and found a weak spot in one of my knees. I avoid riding (including motorbikes) in Sydney like the plague: we live in a very hilly area (like Daddles'), the traffic here is best avoided - and I'm extremely lazy ;).

As to out-doing me - go ahead :). It makes me feel more justified in rabbiting on the way that I do ;).

And I'll use the plane on the LE... I can even do it with the foil screwed down: just a matter of running the plane along the bench on its side, with much greater chance of the new edge being square (not that that is absolutely critical).

Ouch - how did that the disappearing staves happen? Possibly I don't want to know, on second thoughts!

Thanks for the heads-up on the templates and the bench surface. Fortunately the benchtop has been de-hollowed to a reasonable degree, and the templates can be used with reasonable confidence.

Cheers,

Alex.

-

2nd May 2010, 11:40 AM #1664

Yup

Though I usually go up the Expressway Hill.

As for Oakridge - NUP! as in NOPE! as in 'I may be stupid but I'm not crazy' ... but I have done Education Rd a few times so Oakridge may not be such an issue

Funny, I wanted this skiff on the water for last summer so I could build up my core strength rowing every other weekend. Wonder what happened to that plan

As for screwing things down flat and flat work surfaces. Those PDR foils are pretty big critters and it'd be real easy to twist and warp them. Is it here I should point out that Redback's rudder and daggerboard were both made out of one plank of pinus crapiata and neither have warped or twisted despite the lack of care they receive?

Ouch about the disappearing blanks AJ. That's one of the pitfalls of using recycled timber - you get so little out of really big bits after you've fed them through the thicknesser a few (dozen) times.

Richard

-

2nd May 2010, 03:56 PM #1665

The newly-sharpened No. 7 plane has been snorting through the TE quite nicely. As a result of my unfamiliarity with planes for thirty years or so, I'm still "re-learning" to wield the things - especially the big one, as I never got around to using that size. Most tricky is trying to remember to keep my right index finger away from the blade tilt lever, as it is quite sensitive (which probably means that I've got the blade cam set too loose...).

Before doing anything further on the board, I ran a pencil under the depth gauge set at 11 mm around the perimeter or the sides and newly-cut front of the board (the LE stioll retained a highly visible marking-gauge line).

Installed some wedges (left-over scarphing off-cuts from the paulownia mast) under the TE at roughly 250 mm intervals to support it under the quite heavy weight of the big plane. All the more necessary since the TE is getting thinner all the time. The wedges were kept in position by banging some nails into the bench along two edges of each wedge, against the planing direction - belted down way out of range of low-flying plane blades ;). This made things a bit easier, as the rear edge was starting to bounce about alarmingly when when starting the section. The wedges nicely chocked everything solidly in place. Oh, and I'd switched the board around 180 degrees in order to get at that edge easily... Some snaps tomorrow.

Similar Threads

-

New Queensland PDRacer Build

By duncang in forum Michael Storer Wooden Boat PlansReplies: 71Last Post: 26th April 2012, 08:30 AM -

Oz PDR build in Adelaide - sexy black PDRacer

By m2c1Iw in forum Michael Storer Wooden Boat PlansReplies: 39Last Post: 27th April 2009, 06:30 PM -

OZ PDRacer - Dylan's build in the Philippines

By Boatmik in forum Michael Storer Wooden Boat PlansReplies: 16Last Post: 23rd February 2009, 05:50 PM -

Brisbane Timber and Working with Wood. Boatmik/PDRacer

By Boatmik in forum Michael Storer Wooden Boat PlansReplies: 1Last Post: 11th April 2007, 08:06 PM -

Flawed wood on the TS --DUCK!

By Robert WA in forum WOODWORK - GENERALReplies: 7Last Post: 19th February 2004, 11:42 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote