Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 24

Thread: Help me choose a new spindle

-

10th December 2012, 02:39 PM #1

Help me choose a new spindle

Help me choose a new spindle

I am going to buy a new spindle and matching VFD. I am tossing up between the 3KW and the 2.2KW sets.

I was under the impression that the largest motor that could be run on our 220v single phase systems was 2.2KW (3HP). However, there are many Chinese 3KW offerings on eBay now that purport to be able to run 220 volts at less than 10 amps.

I really do want to stay with air cooling as it is one more thing that shouldn't go wrong and I really don't like the idea of water circulating over my table. The 2.2KW motors do not seem to be made in air cooling style.

There are also two new types of motors out now. Both of which are square in shape.

The first and slightlycheaper one is this one.

And another that costs slightly more is here

Does anyone have any advice they can give me and has anyone here actually bought and used one of these motors?

ThanksBob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

10th December 2012 02:39 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

10th December 2012, 04:01 PM #2

I might be wrong but I suspect the 10A rating in the motor data for the 3KW motor from link 1 is the actual phase current, not the total current draw for the system.

Assuming 100% efficiency in the VFD, this would be in the order of 17.4 total at the single phase input to the VFD. Allowing for efficiencies etc maybe about 20A total.

The formula is It = square root(3) x Ip where It = total Current, Ip = phase Current

Hope this helps

-

10th December 2012, 04:21 PM #3

Bob Willson

Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

12th December 2012, 10:56 AM #4

I sent a message to the seller of this.

Asking:

Will this VFD and spindle work OK with a standard 240 volt single phase 10 amp power supply?

The seller replied:

Dear friend Thanks for your enquiry, yes,of course,the VFD and spindle motor suitable for 220V to 240V singel phase 10amp power. Best regards jean

So I sent an offer of $380. Still waiting to get a reply.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

12th December 2012, 11:28 AM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2008

- Location

- Australia

- Posts

- 988

-

12th December 2012, 02:47 PM #6

They are motors, so they draw enough power to overcome their mechanical and electrical losses under no load, and then draw additional power as you apply load to them, with an allowance for the mechanical and electrical inefficiencies.

A 3KW spindle might need 500W say to run no load at max speed.

Load the motor to extract 1KW of output from it, and the power consumption will increase maybe 1200W (1000W for the work done and 200W for increased mechanical and electrical losses) for a total 1.7KW. Increase the load applied to 2KW and consuption will increase again to around 2.9KW.

Ch4iS's post seems pretty well to support the need for 15 A for a 1.5 KW spindle, but at least the start up surge is not an issue as the motors generally start off load and ramp up to speed over a couple of seconds, so here isn't a huge surge when they start.

The commercial CNC I used to operate had an 8KW air cooled spindle. It ran at about 4KW output running a 50mm diamond skimming bit. Most of the other tools it used ran to about 1.5KW to 2KW including a 3/8th compression bit cutting 16mm through cuts in melamine chipboard and MDF at 30m/minute feed rates, so you will get a fair bit of work done with a 1.5KW spindle.

-

12th December 2012, 05:41 PM #7

Thanks for that extra information and explanation malb.

I just got back an answer and it is: This price is very low. Anyway,I accept your offer. Hope you may recommend more business to us. pls check out ASAP

I will buy the pair of them, If it turns out that they draw humungous amounts of power and will not work on 240V single phase at 10 amps, Then I will sell them with an explanation and buy a smaller one again.

I really do hope that they work OK as I feel that I need the extra power to make a decent cut in aluminium. At present, the most I can cut is 6mm dia by a 0.25mm cut. Admittedly I can cut that at up to 2400mm a minute, but it still means 25 trips around the job to get through the full 6mm + 0.1 to make sure that everything is cut right through properly.

I will keep the forum apprised of the outcomes.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

12th December 2012, 09:23 PM #8

We ran a few sheets of 1.6mm ali sheet and a fair few 5mm ali composite splashback sheets. We normally cut these with 3/8in compression bit discards (chipped and blunt) at about 50% feed (15m/min) for full depth cuts without loading the spindle as much as the 16 melamine does so guessing 1-1.5KW spindle input.

I don't know what size spindle you had, but I figure that a 1.5 KW should give you a reasonable cut. If you can't get the feeds up, I suspect that the steppers might be a bit feeble. The machine I was running had 3/4HP servo motors, no hassles with feed power.

-

19th December 2012, 04:25 PM #9

I got the two items today. So his delivery is speedy. The items were well wrapped did not sustain any damage.

Here are photos of the compliance plates on the items and also extracts from the manual. Sorry for the really crap shaky photos, but I couldn't be bothered to do any more.

Manual extract.jpgVFD compliance plate.jpgShake motor plate.JPGManual front page.jpg

The new motor is considerably heavier than the old one.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

22nd December 2012, 09:49 AM #10

Dear solar.jean,

Hello Jean I have received the VFD and spindle in good order and condition. Thank you.

I have some questions relating to the VFD PD setups. I have set the following:

pd001 = 0

pd002 = 1

pd003 = 300

pd004 = 300

pd005 = 300

pd006 = 2.5

pd008 = 220

pd009 = 15

pd010 = 8

pd011 = 120

pd027 = 3

pd028 = 3

pd070 = 2

pd072 = 300

pd141 = 220

pd142 = 10

pd143 = 4 ???? or 2 ????

pd144 = 3000 ???? (required for other Huanyang VFDs) Are these parameters correct for this setup?

Bob Willson

His (or her) reply was:

Dear friend Regarding the wire connection, please connect "R" and "T" to the shingle phase power supply (actraully, connect "R" and "S" or "S" and "T" both are ok.) If you use it as three phase input, then connect three phase power supply to "R, S T". "U, V, W " connect to the spindle motor "1, 2, 3".

If you use this VFD for the spindle motor with 0-300HZ, Please set the parameters of the VFD as our following suggestion step by step, and don't change the sequence:

Step 1: Set PD005 =300

Step 2: Set PD004 =300

Step 3: Set PD003 =300

Step 4: Set PD072 =300 As the orginal factory value setting is 50, so please change the the above parameters according to your motor.

If there have any other questions please feel free to contact with us. pls do it as the above instruction. you'd better get a skilled worker to help you install it,pls don't do it only by youself.there will be better.

Best regards jean Have a good day!

With best regards!

Your sincerely solar.jean

This doesn't actually answer all the questions I asked but it is a good start.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

24th December 2012, 06:21 PM #11

Hi

Can anybody advise what sort of cable I should be using for this 3KW 240v motor.

I have previously bought some cshielded cable that was 3 wires (including earth), but I seem to need a 3+ Earth for this motor.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

27th December 2012, 04:08 PM #12

I need serious help.

I am waaaaay deep in the stuff that comes out of a pig's rear end.

I have also bought a spindle, 2.2kw but water cooled.

I have got the same controller/inverter as Bob

https://www.woodworkforums.com/attach...front-page.jpg

but I didn't get a manual with it and when they finally emailed me one it was for the wrong model. 136 pages of gobbledigook.

I presumed I bought a spindle and a speed control, plugged it in and away you go.

Rude awakening

I haven't got the faintest idea what I am supposed to do with it to make it work.

All I want ti to do is control the speed of the spindle,nothing fancy like oscillation, frequency and all the other stuff the manual mentions.

I have no idea what a VFD is.

It can do PID control but I do not know how to set it up.

Is there some kindhearted genius here who can help me, PLEASE?Every day is better than yesterday

Cheers

SAISAY

-

27th December 2012, 07:18 PM #13

Hi saisay

First thing you need to do is read ALL of THIS

Then, if you need to, come back and ask more questions.Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

-

28th December 2012, 08:45 AM #14

I spent all day yesterday reading it and printing out a LOT of pages, my head was buzzing at the end

Most of the jargon went straight over my head.

Plain electrics I understand but not electronics.

1) does the inverter need to be wired up to the mains? Meaning getting a sparky in?

2) can the spindle be connected up to the control box so it starts when the program starts?

3) I have a speed control knob on the inverter, can I set the speed with that? My control box does not have a speed control facility, only start/stop and emergency stop.

I bought it because I do not like the limitations of 1/2"-1/4" bits in the router, this one has an ER20 collet and a 13 +3 piece set of chucks.

I need to cut some aluminium and the router just cannot handle it to my satisfaction.Every day is better than yesterday

Cheers

SAISAY

-

28th December 2012, 09:31 AM #15

The inverter does need to be plugged into the mains but a sparky is not necessary. This is a simple plug in device that the law allows you to put a plug on. If you are worried then by all means get a sparkybut it will mean extra expense and if, as you say, you understand electricity, then this should present no problems.

Wire and test the vfd side of things and also program it before attaching a spindle.

Yes it can, but again, this requires an extra layer of complexity. It isn't really that hard to do. I had mine set that way but changed it to a manual switch so that I would have greater control.

Yes, you can use the speed control knob on the inverter. On mine, I made a cable about 3 metres long so that the control panel could be used remotely from the VFD. This is very easy to do using IDC plugs. (Insulation Displacement Connectors)

Actually, I made up a separate speed control and on/off switch and mounted them conveniently. I only use the VFD control panel for the speed readout.

Me too. Bob Willson

Bob Willson

The term 'grammar nazi' was invented to make people, who don't know their grammar, feel OK about being uneducated.

Similar Threads

-

Wax or Oil -- help me choose

By ian in forum FINISHINGReplies: 8Last Post: 31st July 2011, 09:57 PM -

Hi - but how did you choose?

By craig_k in forum G'day mate - THE WELCOME WAGON -Introduce yourselfReplies: 2Last Post: 2nd November 2010, 05:21 PM -

Which Vac To Choose

By justinmcf in forum FESTOOL FORUMReplies: 8Last Post: 24th March 2010, 09:54 PM -

Which one should I choose?

By Roll Tide in forum BANDSAWSReplies: 7Last Post: 13th August 2007, 11:12 AM -

How do I choose the right tablesaw?

By Glenn_M in forum TABLE SAWS & COMBINATIONSReplies: 10Last Post: 23rd February 2007, 09:17 PM

Reply With Quote

Reply With Quote

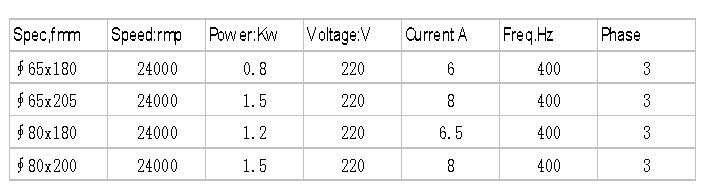

is the information for some other air spindles, so does this mean that the 1.5 KW would draw about 15 amps then?

is the information for some other air spindles, so does this mean that the 1.5 KW would draw about 15 amps then?