Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 17

-

25th March 2016, 01:57 PM #1

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

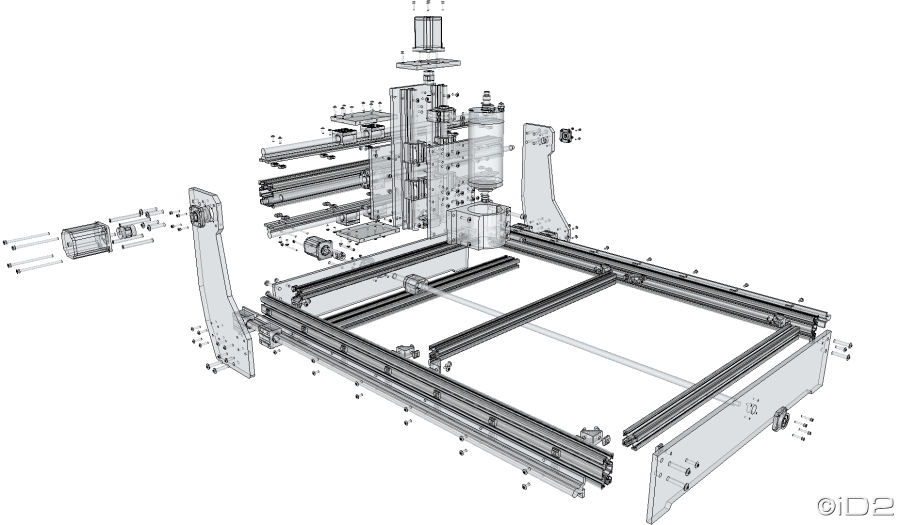

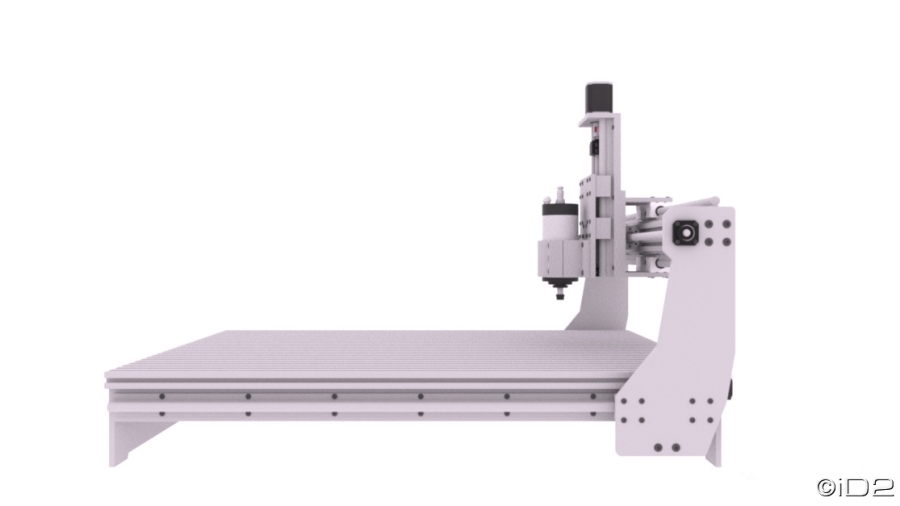

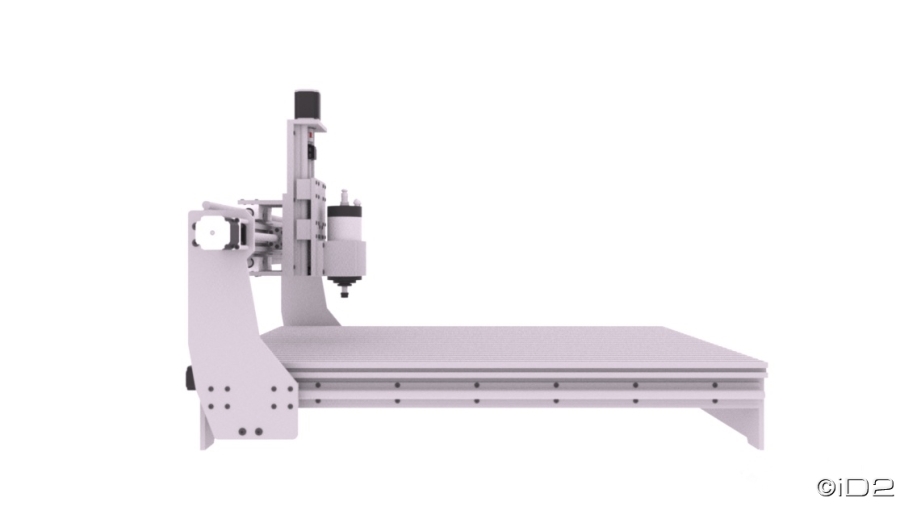

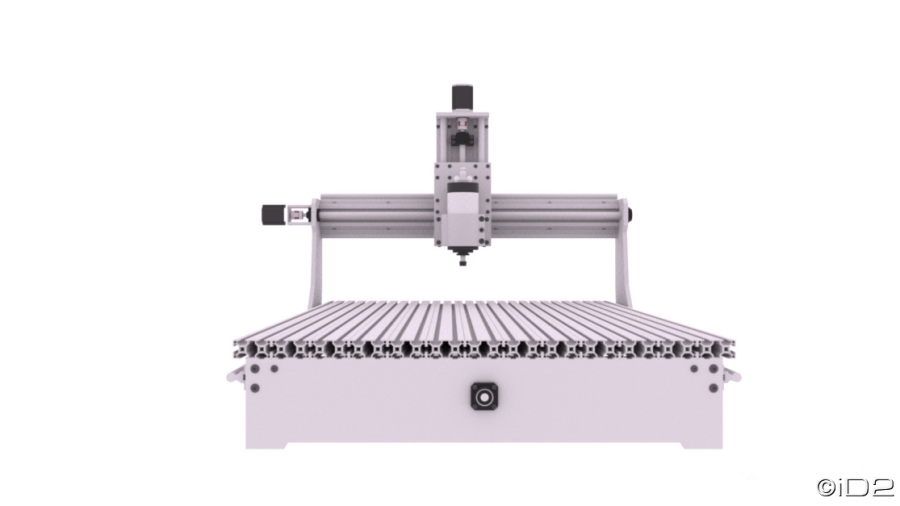

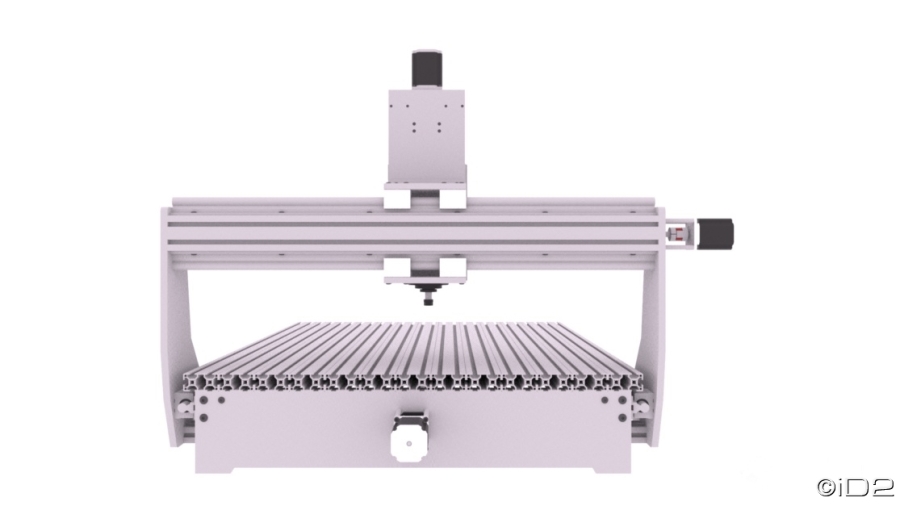

[iD2CNC-SS v.1.0] Aluminum CNC design and build

[iD2CNC-SS v.1.0] Aluminum CNC design and build

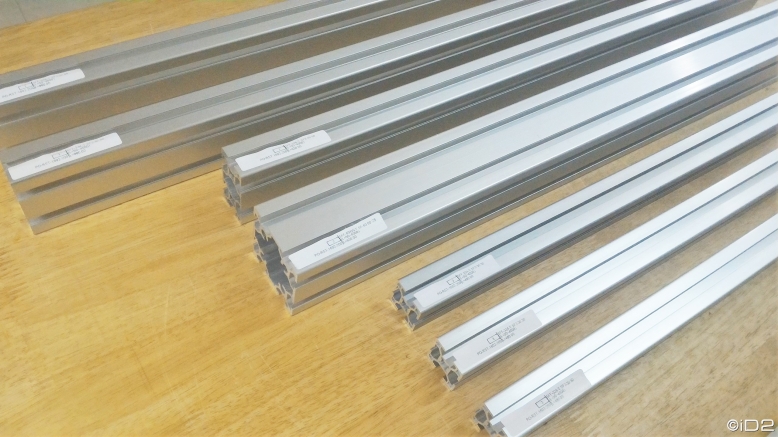

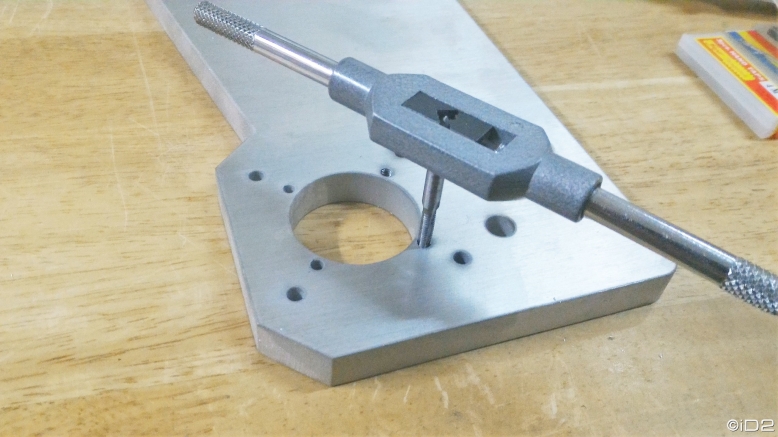

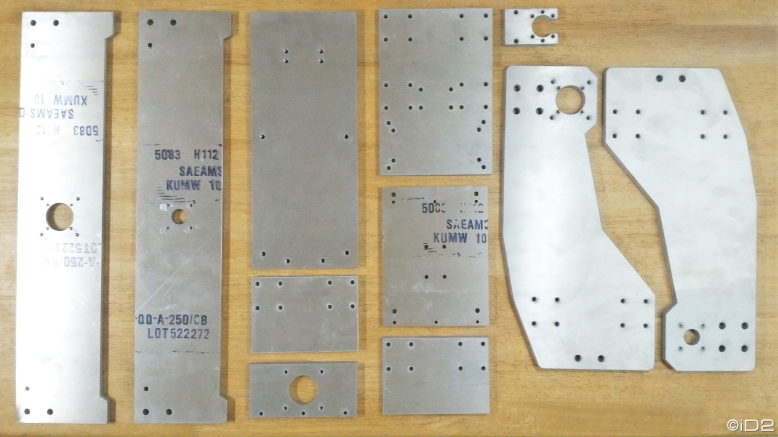

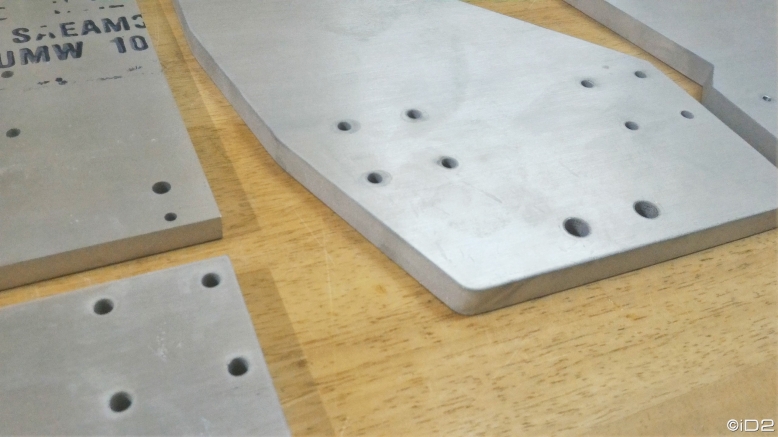

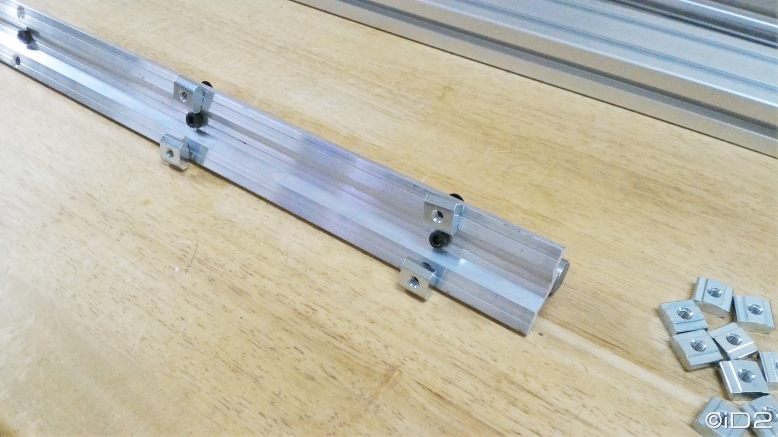

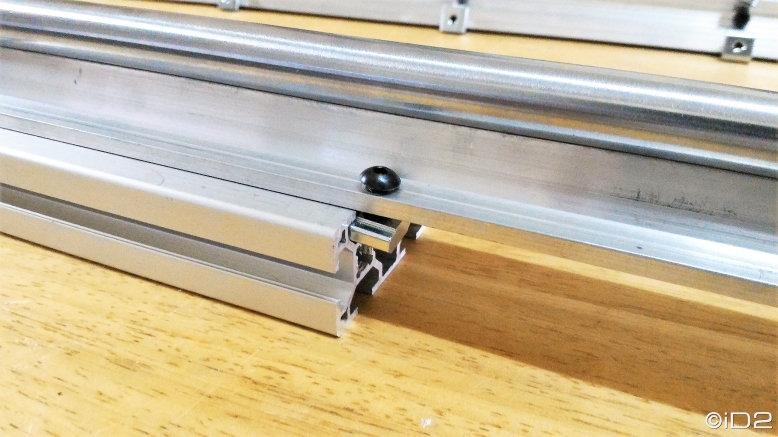

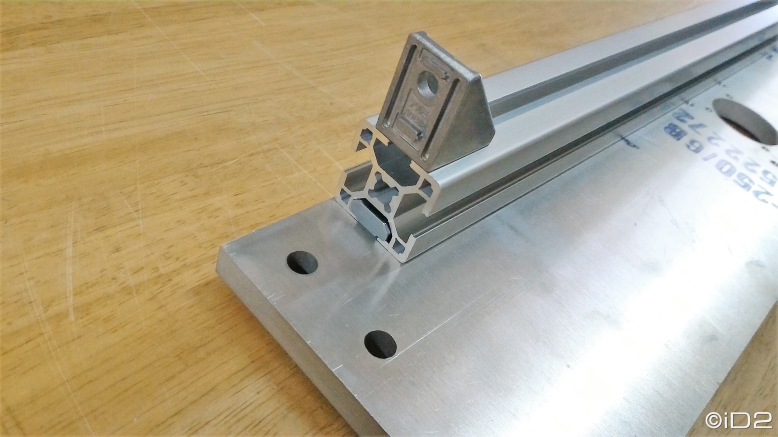

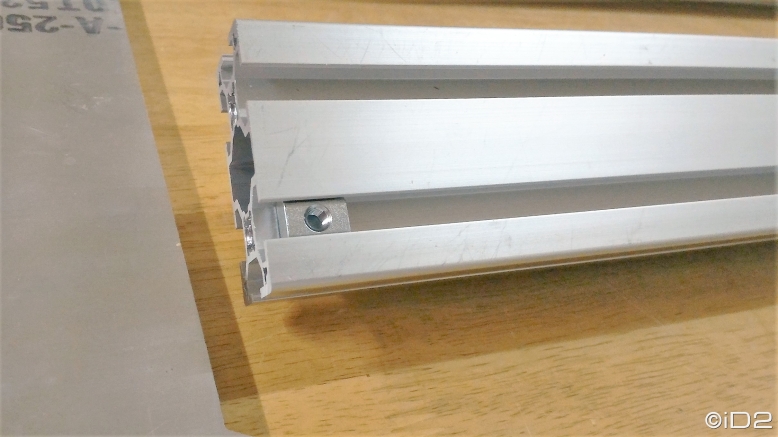

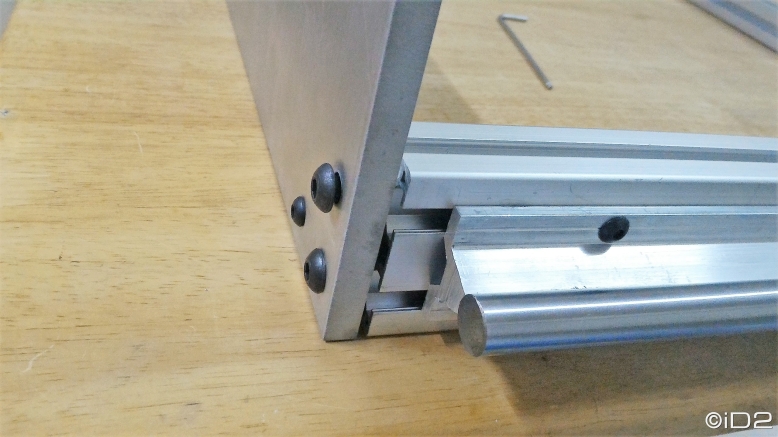

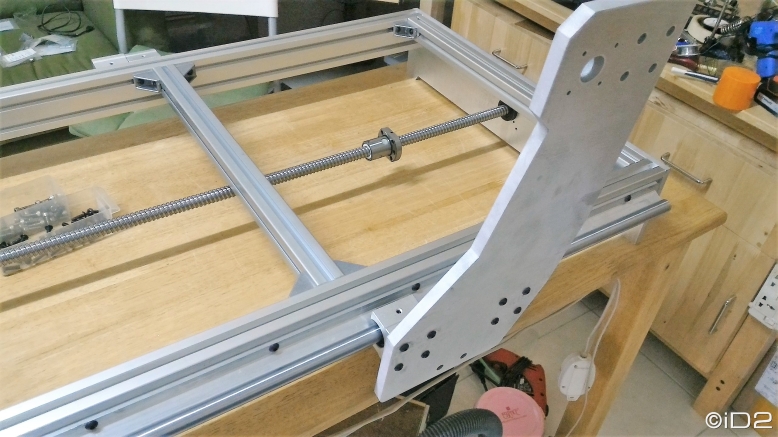

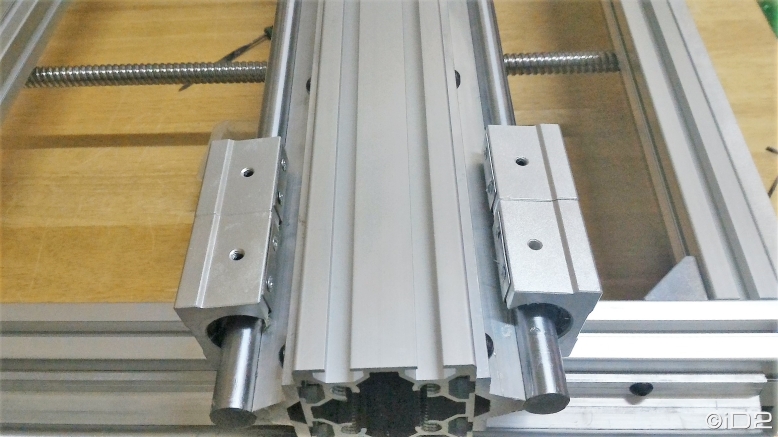

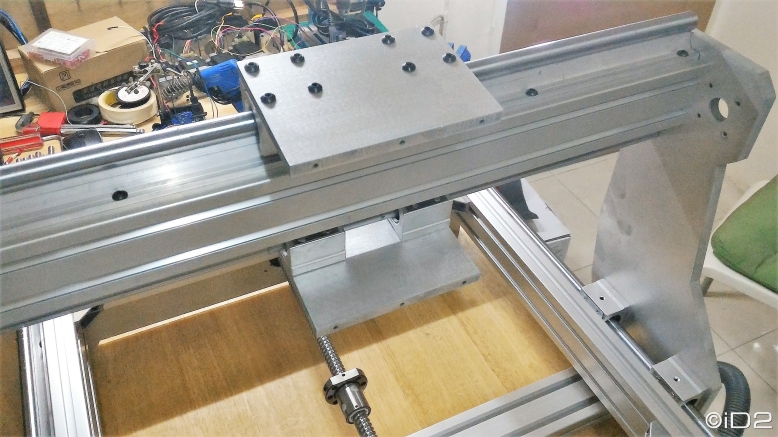

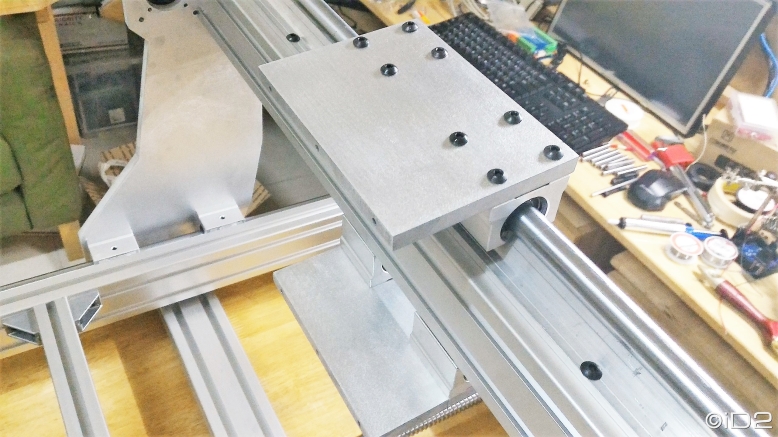

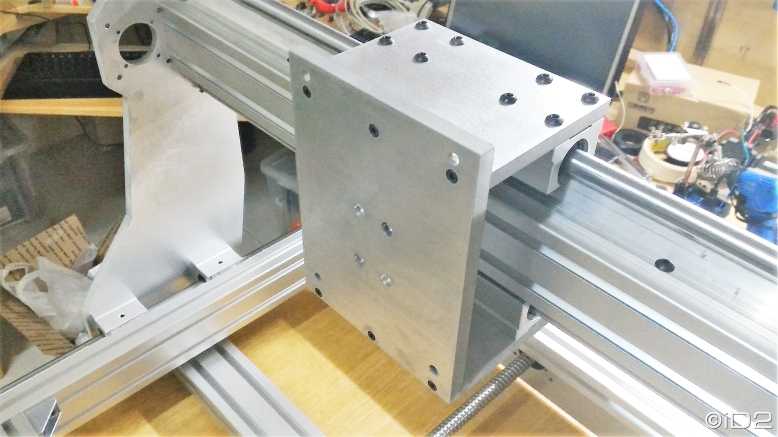

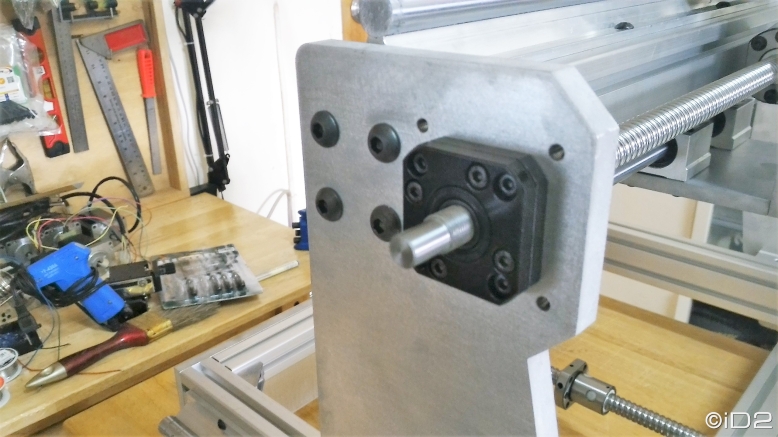

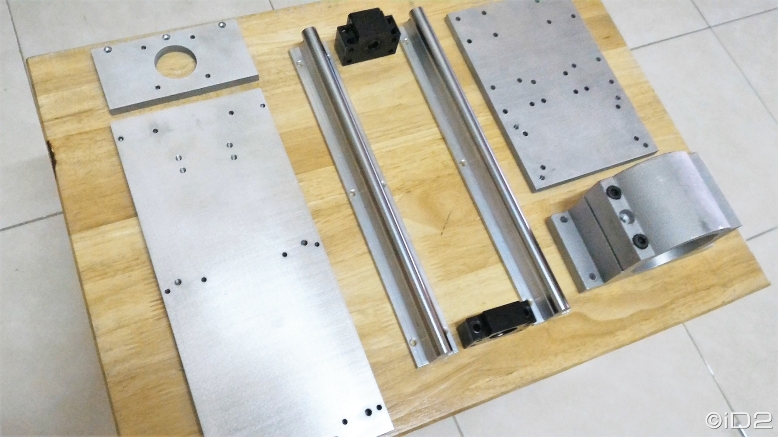

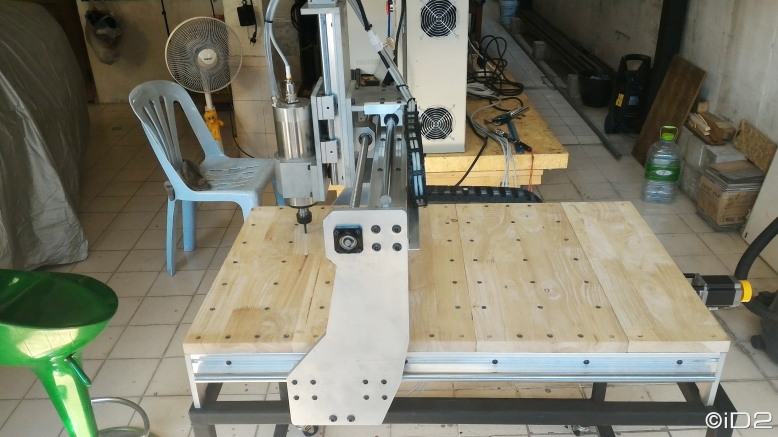

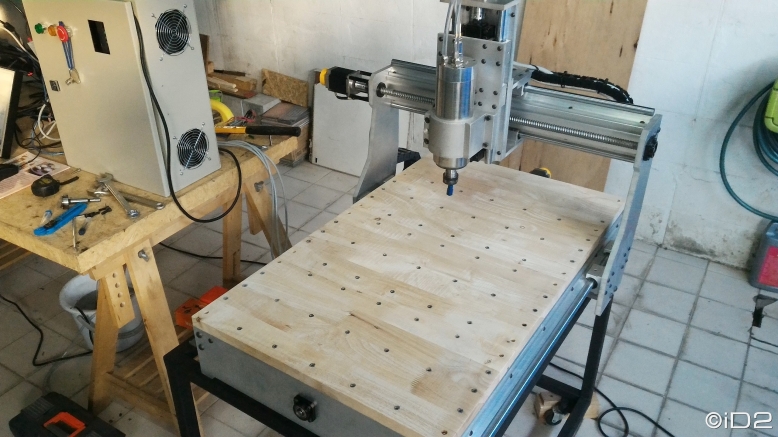

Hello, Now i start my new design for low cost CNC with cost about $1,500 (Include water cooled spindle) , it build from aluminum t-slot profile and aluminum 5083.

This design will have 6 different machine size.

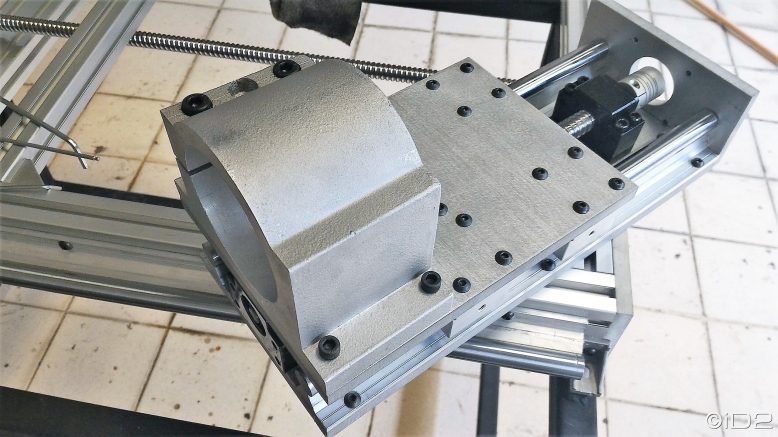

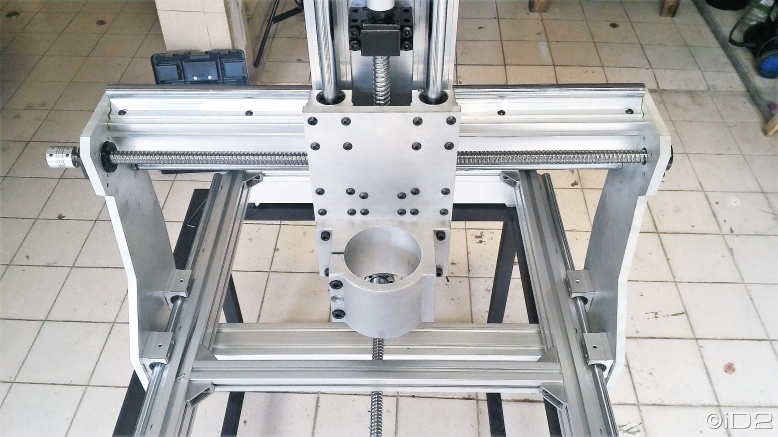

iD2CNC-SS Machine v.1.0 Specification (65cm x 45cm x 15cm , XYZ) :: I will start to build this first

– Machine working area 650mm x 450mm.

– Machine size 1,050mm x 800mm x 750mm (width (X) x length (Y) x height (Z)).

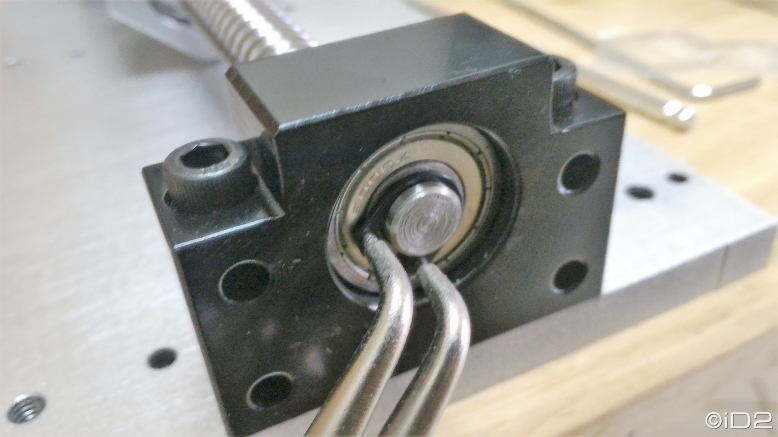

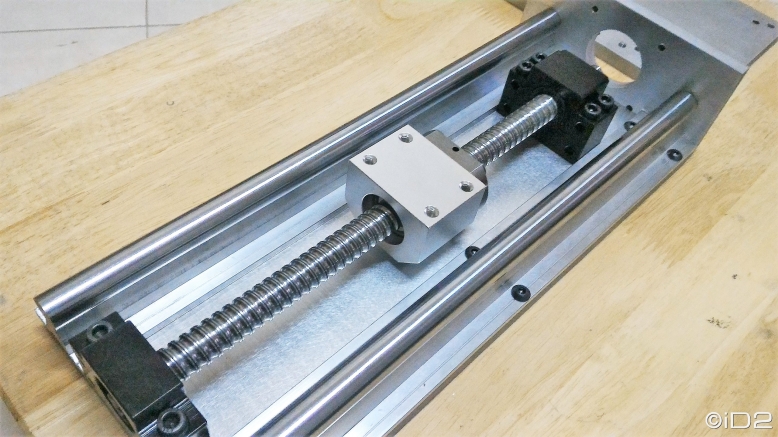

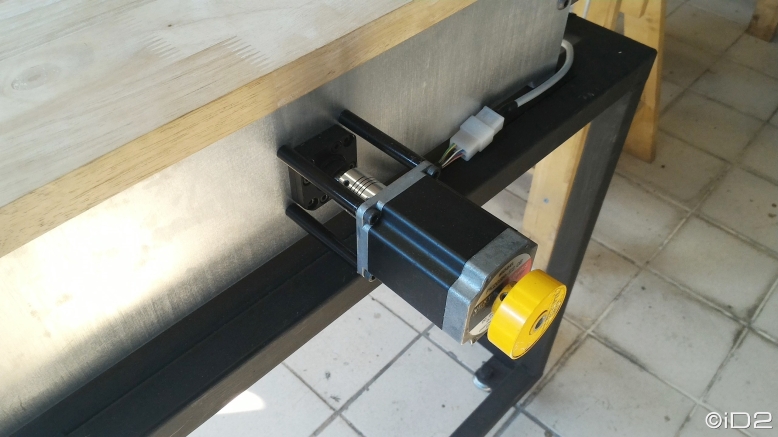

– Linear rod rail size 16mm (RM1605/RM1610) for all axis.

– Ball screw 16mm (RM1605/1610) for all axis.

– Use standard ball screw support BK/BF12 , FK/FF12.

– Aluminum frame use aluminum alloy 5083 10mm & 12mm.

– Design using metric unit (mm).

Other 5 machine size , see detail here --> iD2CNC - SS & SP machine spec

Other cnc build log , see more here --> CNC build log

Other CNC Controlller box build , see more here --> CNC controller box build

-

25th March 2016 01:57 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

25th March 2016, 02:08 PM #2

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

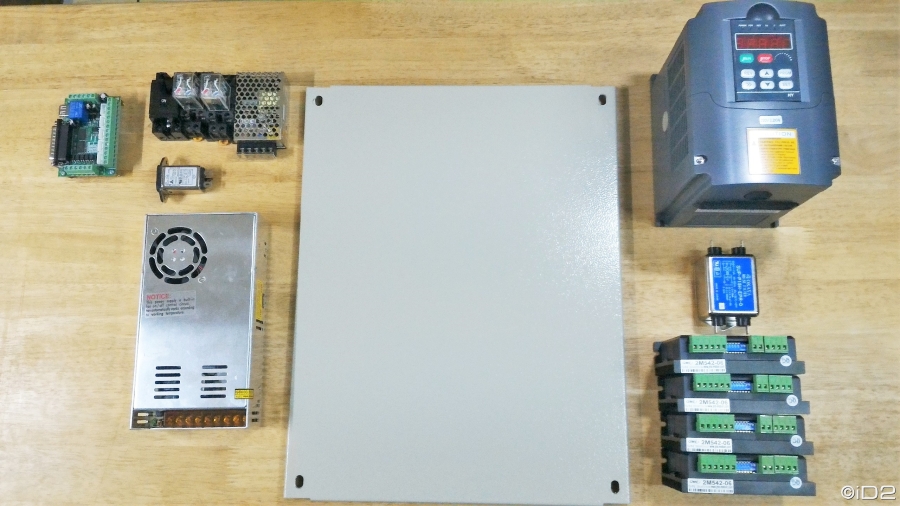

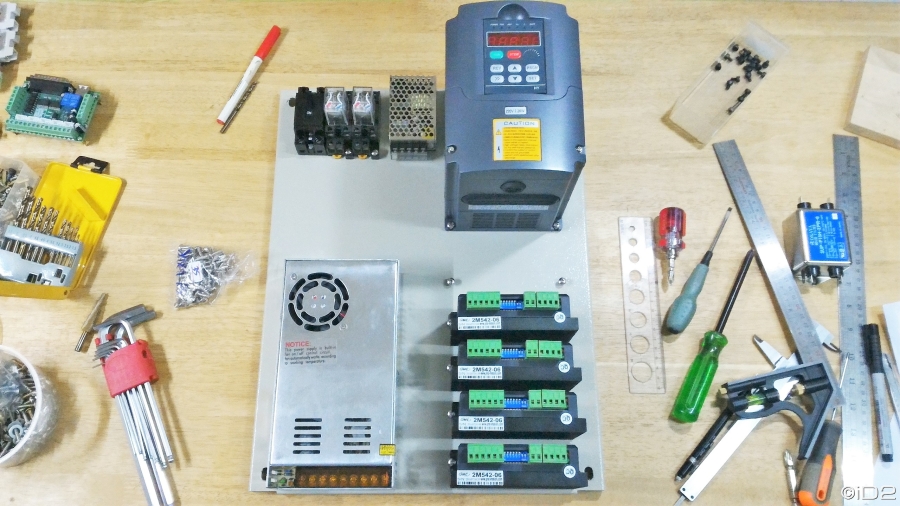

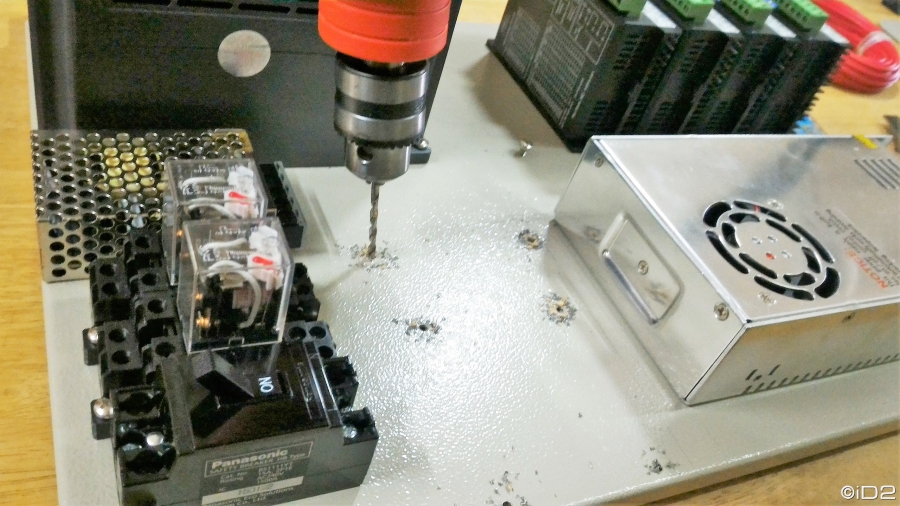

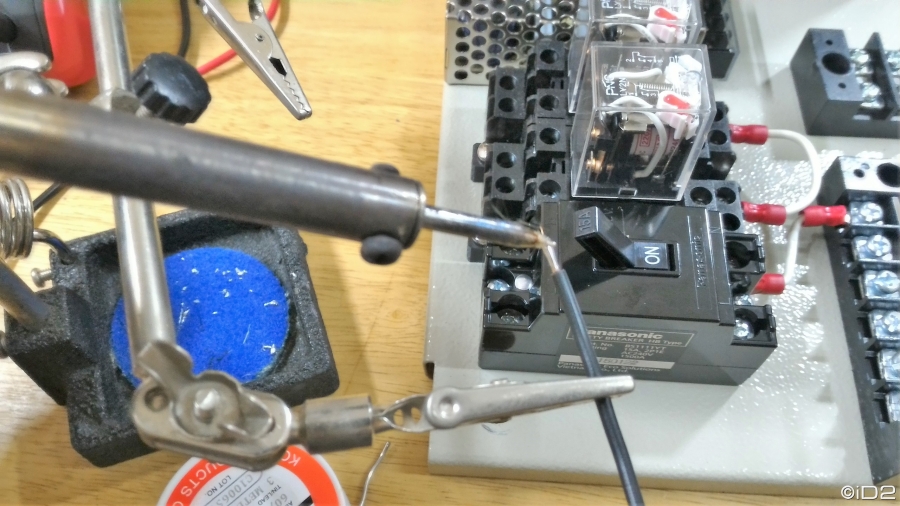

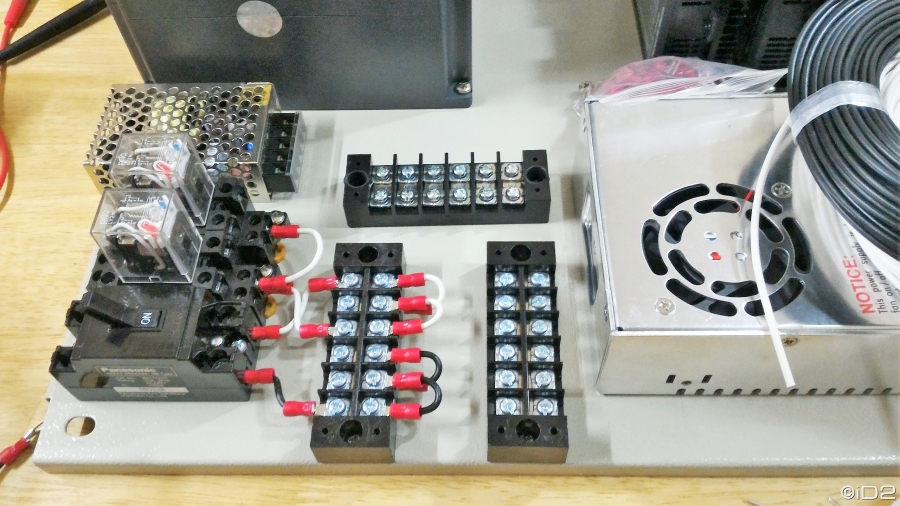

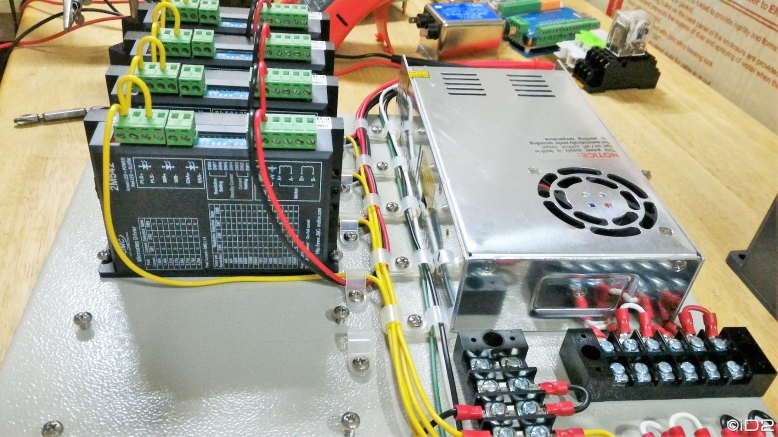

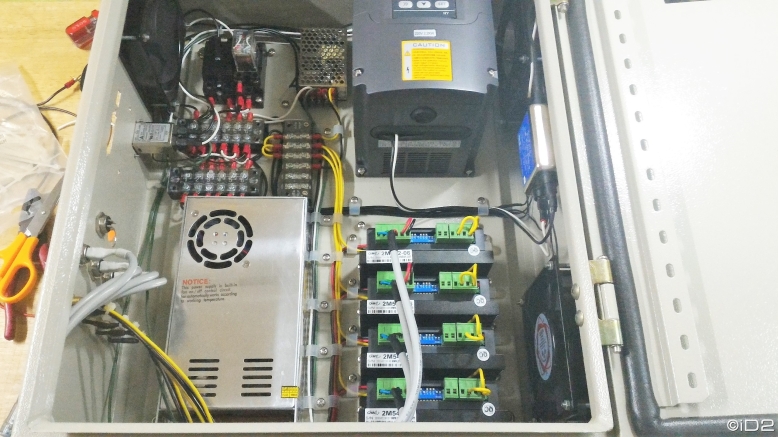

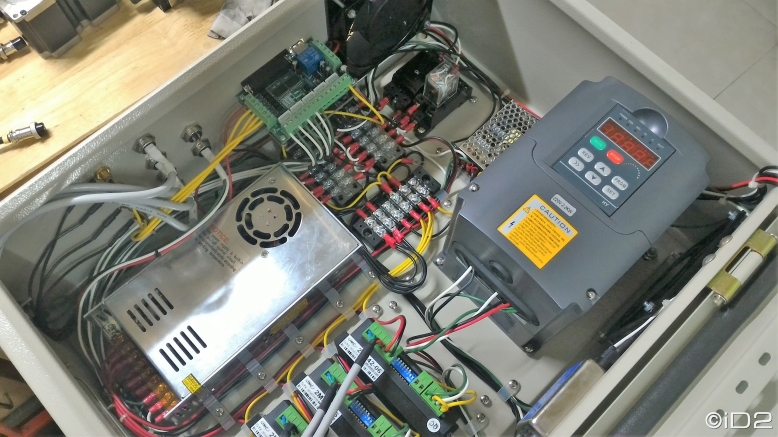

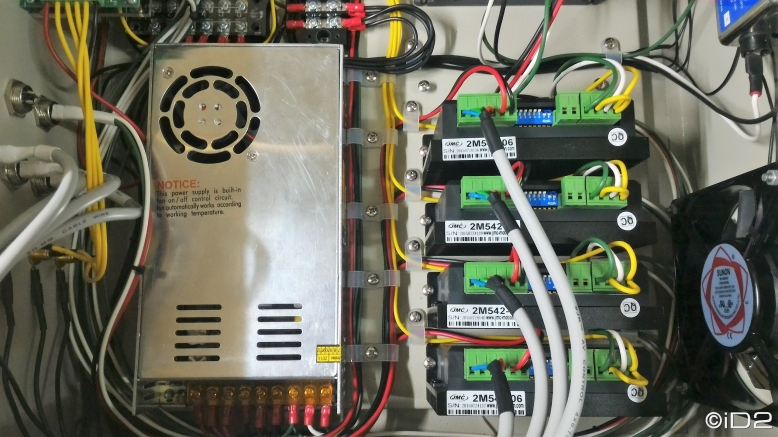

Start with CNC Controller box

[img]href="https://id2cnc.files.wordpress.com/2016/03/p_20160312_1249231.jpg?w=900[/img]

-

10th April 2016, 10:25 PM #3

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

-

11th April 2016, 01:30 AM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2011

- Location

- Murray Bridge SA

- Posts

- 3,339

Hi,

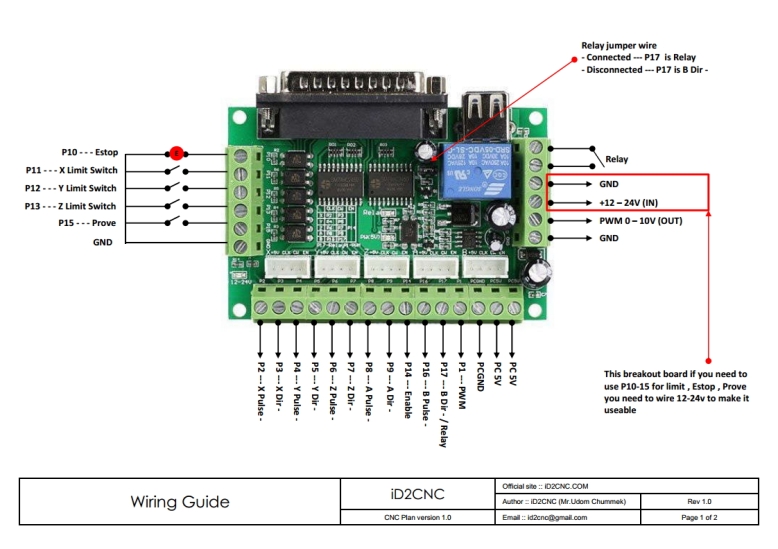

Are you selling these units or the plans? If the plans, how much are they please? Can/will the CNC control box accept a 4th axis? Are you able to draw the wiring diagram if it's able to do so please?

I'm a bit of a dummy, when it comes to electronics and wiring, so this looks good.

Thanks

KrynTo grow old is mandatory, growing up is optional.

-

11th April 2016, 01:26 PM #5

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

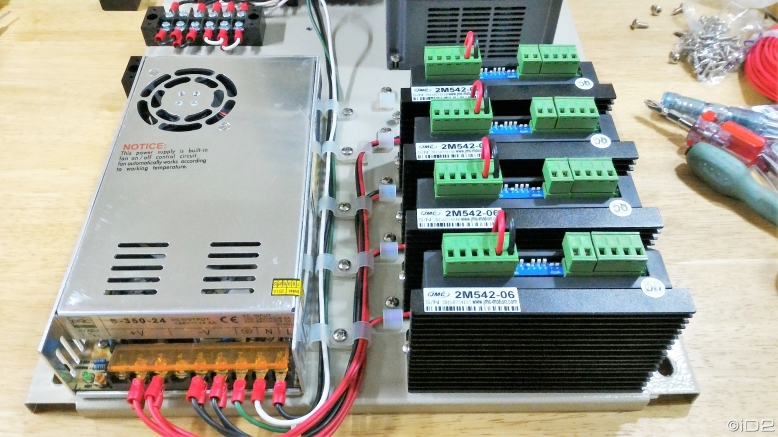

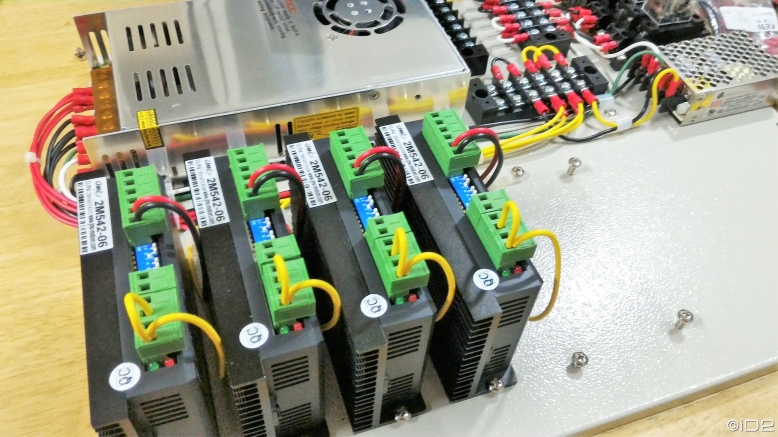

Hi, These unit only sale in my country (Thailand) because it heavy if it ship outside country the shipping cost will expensive. For the plan i will release my iD2CNC-SS v.1.0 plan soon (this plan include detail of machine, wiring,BOM, etc..)

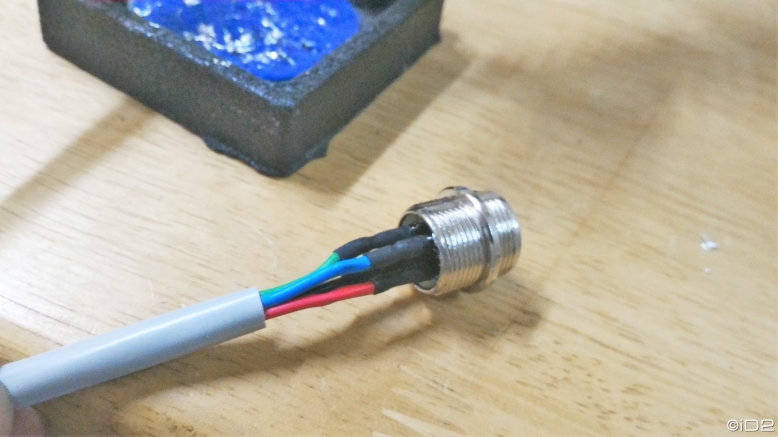

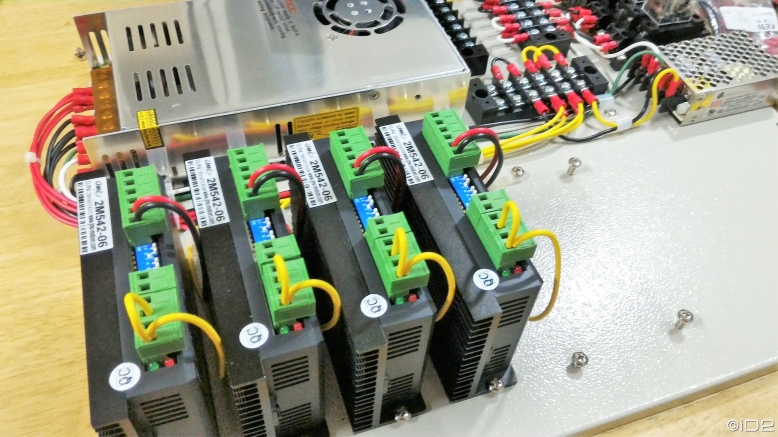

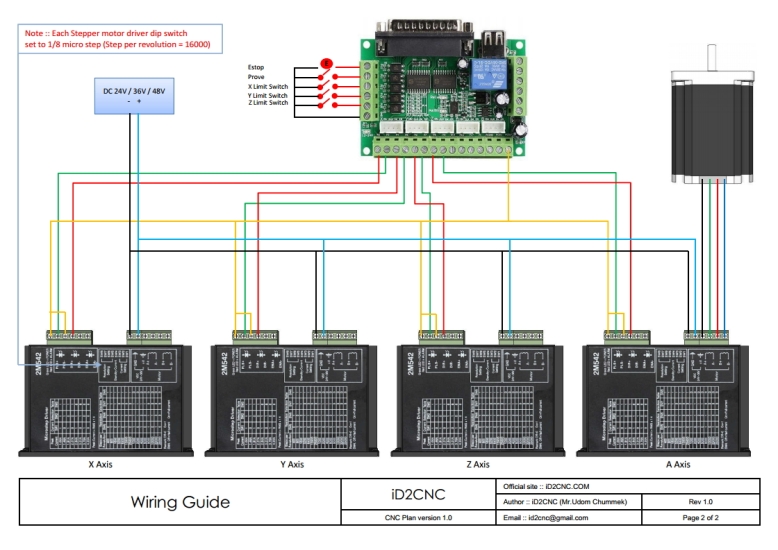

For 3 or 4 axis the wiring was the same just add one more stepper motor driver. You'll see the picture below , the controller box have space for additional stepper motor driver (2 screw that don't mount the stepper motor driver).

(This controller have 4 driver but use for 3 axis machine because machine use dual y axis if need to use 4th axis it need to add one more driver)

Here the wiring diagram (this diagram include with my iD2CNC-SS v.1.0 plan too)

-

11th April 2016, 09:52 PM #6

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

Any particular reason you're going water cooled? Air cooled is pretty much always a better option

-

11th April 2016, 11:31 PM #7

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

-

12th April 2016, 01:18 PM #8

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

-

12th April 2016, 02:50 PM #9

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

Full detail build log --> My Blog iD2CNC.COM

-

8th May 2016, 03:32 AM #10

New Member

New Member

- Join Date

- Jun 2015

- Location

- Poulsbo

- Posts

- 1

I would look into getting the Gecko G-540 4 axis stepper driver for your setup.

And check out CNCzone.com-CNC Machines, CadCam ,Classifieds, Metalworking,Woodworking. it's very robust , and easy to tune, and does micro stepping.

-

19th May 2016, 01:40 PM #11

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

-

19th May 2016, 01:43 PM #12

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

-

19th May 2016, 01:46 PM #13

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

After finished assembly then it time to test cut.

All images , go to see it --> iD2CNC-SS build log

If you like this design --> iD2CNC-SS v.1.0 Plan

-

27th July 2016, 12:58 PM #14

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

test cyclone dust collector & dust shoe

-

28th July 2016, 04:52 AM #15

Intermediate Member

Intermediate Member

- Join Date

- Jul 2013

- Location

- Asia

- Posts

- 33

Just upgrade my dust shoe , change the guard from plastic sheet to rubber foam , it will better than plastic sheet like i did before. This's just an idea for dust shoe

.

.

.

.

.

.

.

.

Similar Threads

-

Scratch Build :: DIY Aluminum CNC , by iD2

By iD2 in forum CNC MachinesReplies: 25Last Post: 3rd October 2015, 11:58 PM -

DIY Design and Build Kayak

By anewhouse in forum KAYAK & CANOE BUILDINGReplies: 9Last Post: 2nd January 2015, 07:23 PM -

Dorade Box Design & Build WIP

By Lord Nibbo in forum WOODWORK PICSReplies: 13Last Post: 28th February 2011, 10:35 AM -

New Build..New Design

By floody_85 in forum MUSICAL INSTRUMENTSReplies: 96Last Post: 20th June 2010, 11:48 PM -

80/20 Aluminum Design Verification

By ttjarrett in forum CNC MachinesReplies: 5Last Post: 9th April 2009, 05:29 PM

![[iD2CNC-SS v.1.0] Aluminum CNC design and build](https://www.woodworkforums.com/images/misc/arrow.png)

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote