Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 8 of 8

Thread: Playtime

-

13th March 2008, 11:00 AM #1

Playtime

Playtime

Had a bit of a play with some big routers on Tuesday.

I went to a meeting at Byron Bay so dropped into my brother's business on the Gold Coast.

He's running two Morbidelli machines that go pretty much all day.

I was very impressed with the speed and precission of these machines.

The two machines in question.

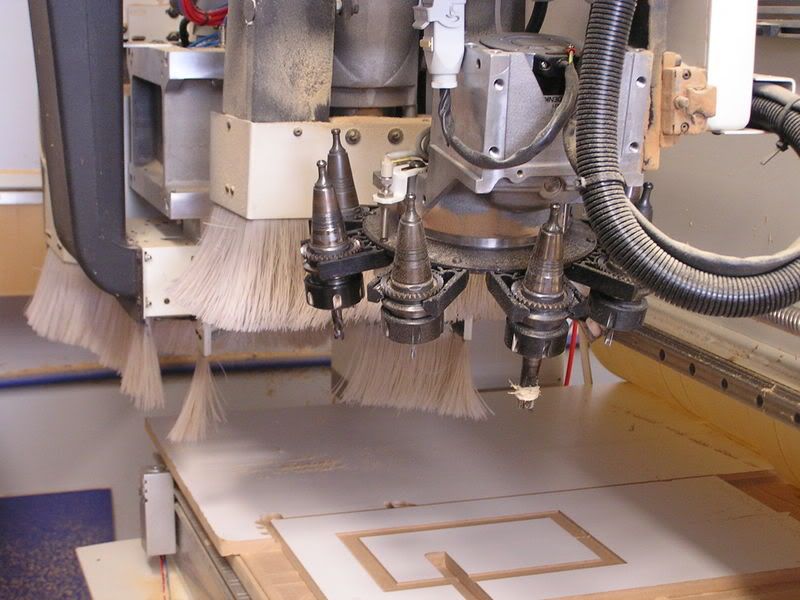

Bit selection head. There's also (I think) 12 drill bits and a saw blade that can be selected.

This bit was doing 18k revs and was scribing a part number onto the 18mm ply

These are the finished bits. Internal structure for a 65 foot luxury yacht or power boat (not sure which)

Some very nice toys. Wish i had one to play with more often.

Just thought some might be interested in having a look.

-

13th March 2008 11:00 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th March 2008, 08:58 AM #2

Hi,

They sure are BIG just a bit bigger than our hobbyist machines

just a bit bigger than our hobbyist machines

Thanks for the piccy's

-

14th March 2008, 05:08 PM #3

It nearly as big as the one virtual one in my shed with all the other virtual tools

.

.

Thanks for pics mate much appreciated any chances of getting some finished pics from ya brother of the boat its going into?

Tell him to jump online if he has half a chance, we would love to hear from him.

Once again thanks

WillyI like to move it move it, I like to move it.

-

14th March 2008, 05:24 PM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2003

- Location

- Perth WA

- Posts

- 3,784

I love to have one of those sitting in my shed.

Thanks for the run down and piccies.Cheers,

Rod

-

16th March 2008, 02:53 AM #5

No pics of the boat i'm afraid. He just gets an order from the boat people for a complete set of 58L or whatever. When the shipwrights/boat builders make a new model they make all the pieces by hand and then send them to my brother to program into the machines. When they get an order for a boat they send him an order and the machines do their thing. The bits in the photo will be covered in fibre glass so just plain ply. Other bits are either solid timber or veneered ply depending on where they go in the boat.

He's suggested to the boat company that they give him one of the boats purely for reference in case he has a problem. Don't think they've come through on that one yet.

Don't think they've come through on that one yet.

-

16th March 2008, 02:59 AM #6

In the second photo, bit selection turret, he was setting up on a couple of bits of scrap for some cupboard doors.

Notice the square inside corners. You regular CNCers may find it easy to get square corners but i was stumped as to how he did it.

-

16th March 2008, 12:00 PM #7

-

17th March 2008, 06:37 PM #8

Cabinetmaker

Cabinetmaker

- Join Date

- Feb 2008

- Location

- Toowoomba

- Age

- 43

- Posts

- 13

to get the square corners it just slimply runs the "V" bit up the corner to the top of the board. Just another subroutine. We use much the same set up at my work but its a twin bed biesse rover that way when one side is drilling and routing the sheet we can unload the other.

Reply With Quote

Reply With Quote