Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 46 to 60 of 80

-

27th June 2008, 03:46 PM #46

Novice

Novice

- Join Date

- Jun 2008

- Location

- Houston

- Posts

- 14

Hey guys, first post so dont gang up on the nooblet.

I just bought my first house so now I have a HUGE garage to build my shop in. so far I have the basics, good large table saw, router table, planer, jointer, 900 clamps etc.

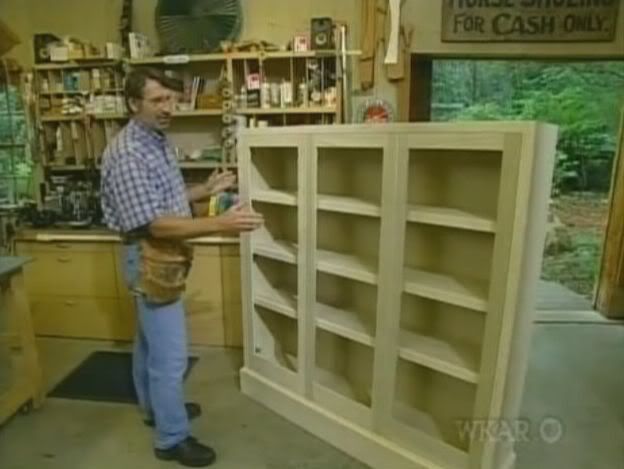

My first BIG project is the greek revival bookcase I saw on NYW a few months ago and fell in love with, its going to be the same size, painted dark dark brown (nearly black) with some nice LED lights lighting the inside.

-

27th June 2008 03:46 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

27th June 2008, 04:49 PM #47

AllegedlyJeremy

AllegedlyJeremy

- Join Date

- May 2008

- Location

- Swan View WA

- Age

- 45

- Posts

- 228

-

27th June 2008, 08:21 PM #48

Hi afx, good looking bookcase, what type of timber have you used? I also like that sign over your door "for cash only" what does the rest of it say?

Thanks Ray, the suspended look is good. The timber looks so heavy but then it just floats through and looks light at the same time. Wasn't light putting it in place thats for sure.

DJ one hellova letter box, will look fantastic though. Definitely falls into the big category.

-

27th June 2008, 09:52 PM #49

-

28th June 2008, 02:09 AM #50

Novice

Novice

- Join Date

- Jun 2008

- Location

- Houston

- Posts

- 14

-

28th June 2008, 02:10 AM #51

Novice

Novice

- Join Date

- Jun 2008

- Location

- Houston

- Posts

- 14

-

28th June 2008, 08:43 AM #52

Sorry for the case of mistaken identity, obviously we're not familiar with old mate Norm or the Yankees shop.

-

28th June 2008, 11:39 PM #53

Just starting my next furniture project a light weight (about 70kgs at present) little coffe table. Some of you may recognise this little nugget of Redgum from the Sydney Wood Show, Tim & Barry had it on there stand in the court yard. Taking out some of the chainsaw gouges with the adze but it is to remain rough and rustic.

-

12th July 2008, 01:47 PM #54

Finaly got the coffee table done now weighs about 100kgs with the Redgum top and the 100 year old wrought iron skirt. Oops forgot to put the photo in.

-

14th July 2008, 06:02 PM #55

On the go

On the go

A bit belated in picking up on this thread.

Just completed coffee table marrying a red cedar slab to an earlier cabriole leg table frame.

In progress a cedar TV etc stand and cabinet. 1350 X 550 X 450. Top glue-up done, ready for planing /flattening. Corner legs/frame laminated up and sized, ready for mortises/tenons, but proceeding slowly.

Done cleanup and sizing of the timber I also kindly got from Boban, together with Oregon "salvaged" from demolition site next door, so bench is in early stages.

regardsLast edited by Alastair; 14th July 2008 at 06:02 PM. Reason: typo

Alastair

-

14th July 2008, 08:50 PM #56

Photos Al, where are the photos man???

-

4th September 2008, 01:43 PM #57

Posted a design for a library earlier on page 1 of this thread and it's getting close to completion. Here are some dodgy photos of the installation so far. That tall guy is Bill my builder mate who offsided for me on the job. He's an offsider because he's so tall he has to stand off to the side for me to crane my neck to see his face.

I've now got the skirting on (that was a fun job scribing it to match the dodgy slate floor- not) and am awaiting doors and a paint job by the client to complete it. It's made of gaboon veneer paulownia blockboard mostly, supplied by the client's business. It's a nice light material to work, but this specific product isn't what I would call furniture grade, the veneer has a number of imperfections.

This is the client who wanted to negotiate my price down, fortunately I didn't because it has well and truly overrun now. It's a matter of pride to complete it. I just got a phone call requesting more shelves and at a "reasonable" rate please.

Cheers

Michael

BTW it was made offsite into components, two matching bookcase sections with pine cabinet tops, 4 boxes for cabinets, 2 ladders for plinths and the central vertical section as one unit. 13 sheets of blockboard and 4 sheets of ply. I had to deliver it in SWMBO's new horse float it was so big.

-

4th September 2008, 05:44 PM #58

-

4th September 2008, 07:38 PM #59

Mickyd, looks fantastic, I think it may have been said on this thread before but big jobs take linger than small jobs. We always need to quote high with big projects, it takes longer to pick up the bits, move the bits, have somewhere to store, enough space and saw horses/benches, need mates or colegues to help move and install things. Yes and then some %^)#*wit.......... wants you to do it for free. Keep up the big work Mickyd

-

4th September 2008, 08:41 PM #60

Similar Threads

-

My box making jig

By jow104 in forum BOX MAKINGReplies: 7Last Post: 27th March 2008, 06:22 PM -

Pen Making

By Jaydo in forum WOODTURNING - PEN TURNINGReplies: 7Last Post: 15th March 2007, 06:43 PM -

Pen Making

By Froggie40 in forum WOODTURNING - PEN TURNINGReplies: 0Last Post: 19th September 2006, 07:23 PM -

Bow making

By Brody in forum WOODWORK - GENERALReplies: 42Last Post: 24th August 2006, 07:11 PM -

Bow making

By Brody in forum TIMBERReplies: 16Last Post: 14th May 2005, 07:10 PM

Reply With Quote

Reply With Quote