Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 76 to 90 of 195

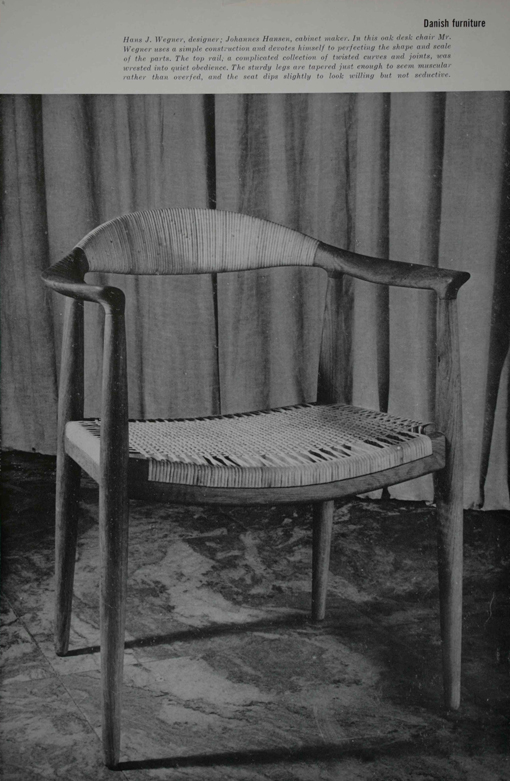

Thread: Building Wegner's "The Chair" .

-

15th January 2014, 07:44 PM #76

-

15th January 2014 07:44 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

16th January 2014, 08:13 AM #77

-

16th January 2014, 08:20 AM #78

-

18th January 2014, 02:38 AM #79

How would you ...

How would you ...

The Chair is nearly at a point where I can begin to think of a glue up. Well, that's really getting a little ahead of myself. What I mean to say is that the stretchers are nearly done. Basically, there is one significant (through mortice) and one minor task (rounding the sides) to complete, and then it is ready.

This is where we are ...

All the coped joints have been fine tuned ..

Before the side edges are rounded, a through mortice (I'm not sure what else to call it) needs to be created in each of the stretchers for the Danish Cord seat. The through mortice runs nearly the full length of the stretcher, beginning and ending 30mm ( 1 1/4") from the ends. It will be 3mm (1/8") wide and through the middle of each stretcher.

This is what it will look like ...

Now here is where I could do with your thoughts: how would you create this through mortice with hand tools? Power tool of choice would be a router. That would be an easy process.

My first thought was to saw it out with a coping saw and then clean up the edges with a rasp and file. I practiced on a scrap and decided that this would require too much cleaning up. The saw blade tended to wander with the grain, and the through mortice was too narrow to saw two parallel kerfs.

The other method is to use a mortice chisel. Chisel half-way from each side of the stretcher.

Keep in mind that the front and rear stretchers are compound curves. The side stretchers are straight.

It should be straight forward: score the sides, and chop out the waste. Well, scoring the sides is not straight forward for the compound curves. To begin, a cutting gauge needs to have the appropriate fence to follow a curve. OK, so I can do that.

I practiced on scrap ...

In this wood a single blade cutting gauge was not reliable. Even with initial light passes, the blade wandered with the grain enough that the mortice was in danger of wandering off course or widening. A mortice gauge would be better, but I did not feel like making one with the correct fence specifically for this project.

It occurred to me I could use the Veritas inlay cutter for the Veritas router plane. This has a fence that will follow a curve.

This has twin blades to score a parallel line for inlay ...

This is the line created (lower example) ..

Chopping out the waste with a 1/8" mortice chisel was OK ....

.... however, I can see that this will take time to do.

Anyone have another idea?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

18th January 2014, 04:43 AM #80

What do you feel about a pedestal drill? Obviously that could be done by hand, but ...

-

18th January 2014, 07:02 AM #81

Derek

I suggest you try a Japanese saw. The Azebiki is designed specifically to cut through in the centre of a board, and therefore does not require pre drilling or mortising, I only have a very small one, in crosscut. a larger one could be obtain in Kataba style with rip teeth and can be used to cut on large radius curves. Alternatively you can use a Kataba with rip teeth, using only the first tooth ( which is quicker than you may imagine, but perhaps a bit slower in Jarrah ) until you have the whole blade through, but I doubt this will handle the curves.

Stu may be able to offer something to suit and better than the norm for your material.

Another option if you have a little spare material with close matching grain, would be to rip and clean each piece up, then glue in a section at each end to form the groove and clean up the joints ( again !). I think this may be the simplest option and present the least difficulty with regard to cleaning up the groove after the initial cutting.

Incidentally, Danish cord has a reputation for being murderous on fingers when weaving seats.

Regards

-

18th January 2014, 08:31 AM #82

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

The Japanese saws are fine in straight grained softer timbers. I shudder to think

what difficult job it would be to use one in this situation.

The option of the Veritas inlay device and the mortice chisel seem the best.

-

18th January 2014, 09:02 AM #83

Nope, other than to make sure something soothing is playing on the radio. I'd just take my time and work to the centre (very carefully!) from both sides. Mind you, I don't think I have ever tackled anything as daunting as that titchy narrow mortise in such curly hard wood. Getting clean cuts in that will sort the men from the boys!!

Cheers,IW

-

18th January 2014, 10:18 AM #84

Artme

Japanese saws never cease to impress me and I have used them on various wood species, including Brigalow which is rated at 10 on the Janka hardness scale compared with 8.5 for Jarrah. This alone does not mean that any Japanese saw would be guaranteed to do the job for Derek as his wood may be too cranky for the task to be accomplished, However, I think it is worth Derek discussing with Stu. If Derek already has a Kataba saw it would be a simple exercise to try on a piece of jarrah.

Softwood is used a lot in Japan, but so are Hardwood species such as Oak, which can be hard and cranky.

Regards

-

19th January 2014, 12:18 PM #85

Hi Derek,

I would try a scratch stock, It would be a nice hard work out but will give the accuracy you need, I think. It may be that you could scratch in a channel from both sides 5mm deep, with the scratched in channels acting as a guide, then chisel the rest out .

https://www.google.com.au/search?q=s...w=1344&bih=673

Rob

-

19th January 2014, 05:23 PM #86

After Rob I was imagining a skinny dado 'plane' ... then I saw this on ebay .. Antique 1800s Coack Makers 2 Blade Router Plane Wood Tool Cutter Groove | eBay

double router.JPG double router 2.JPG

and I went looking for 'groove cutter'. Lots of corded stuff, but also ... for luthiers' stringing ... purfling cutter which has come up before ...

Which purfling cutter to get? - The Pegbox - Maestronet Forums

string purfling.jpg

Something like this?? score the edges, remove the centre + repeat?

or your vertical router/scraper?

Stringing Cutter for Router Plane by Derek Cohen

Paul.

-

19th January 2014, 09:56 PM #87

Paul - that "Coack Makers" tool looks like an over-grown scratch stock. I don't think it would cut a deep mortise very efficiently, & purfling tools are for making very shallow grooves (in soft wood!), probably less than an eighth of an inch deep, in all but rare cases.

I think traditional methods are likely to prove the simplest & most efficient, really. Defining the edges with something like a cutting gauge and/or deepening the edges with a sharp chisel will reduce chipping of the sides, but I reckon there'll still be a fair bit of chipping along the edges, in that wood unless great care is exercised. He's probably taken courage & just chopped 'em out quite successfully, by now, anyway....

Cheers,IW

-

19th January 2014, 11:24 PM #88

A Quirk Router! The blades would make things a bit easier . They have a double scribe /skate/ anti over feed thingy before the cut. And an adjustable compass plane type fence . Nice.

See the link to images

https://www.google.com.au/search?q=q...h=673#imgdii=_

Here is a close up of a blade of a Preston , looks to ave a broken spur on the other side.

Rob

-

20th January 2014, 04:33 AM #89

Slotting the Stretchers (Pt 2)

Slotting the Stretchers (Pt 2)

This was todays work:

http://www.inthewoodshop.com/Furnitu...rs%282%29.html

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

20th January 2014, 07:50 AM #90

Well done Derek,

You will soon have a Blackwood and Jarrah versions of " The Chair "

I will look forward to seeing in the future, a line up of these around your dining table, perhaps with one in Oak, Beech, Ash. etc then you can try a series of different construction methods and perhaps various seats. Perhaps the last one ( #8 ?) could incorporate your design improvements to make the ideal version for a hand build.

Gambatte !!

Similar Threads

-

Anyone in Perth own Wegner's "The Chair" ?

By derekcohen in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 14Last Post: 21st February 2014, 02:30 PM -

Building the Atkin sailing dinghy "Vintage"

By jalmberg in forum BOAT BUILDING / REPAIRINGReplies: 9Last Post: 14th February 2011, 02:37 AM -

"white-faced building board"

By Soren in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 2Last Post: 18th January 2011, 11:07 PM -

Building a "50th anniversary" Hartley TS21

By SimonP in forum BOAT BUILDING / REPAIRINGReplies: 12Last Post: 18th June 2010, 11:14 PM -

Great New "Martin" Acoustic Building Manual

By Beachcomber in forum MUSICAL INSTRUMENTSReplies: 8Last Post: 14th July 2008, 07:06 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote