Needs Pictures: 0

Needs Pictures: 0

Results 136 to 150 of 187

Thread: Lingerie Chest

-

30th December 2015, 08:19 AM #136

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

As usual Derek you have given us an excellent WIP and a beautiful finished piece!!!

I particularly appreciate your willingness to partake in debates and discussions. I think we

all learn so much from them.

Have a great trip !!

-

30th December 2015 08:19 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

9th February 2016, 12:52 AM #137

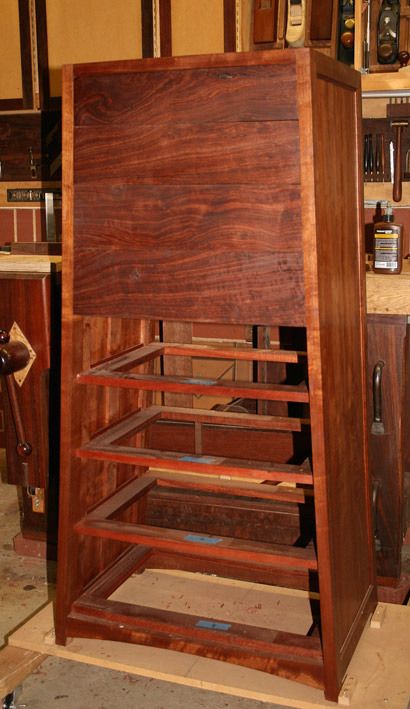

Four down, four to go ...

Four down, four to go ...

Just a quick update on the Lingerie Chest.

Four drawers done. They take 3 full days each to build (1 1/2 weekends). This includes thicknessing/sawing/shaping all the parts, dovetailing, and fitting.

The gaps between the drawers will be sorted out once all are done. There will be 1/16" between the drawers.

And the obligatory dovetail shot

The dovetails increase progressively, as with the size of the drawers.

Next post will be after all the drawers are done.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

9th February 2016, 01:18 AM #138

Senior Member

Senior Member

- Join Date

- Oct 2015

- Location

- Perth

- Posts

- 298

Simply beautiful Derek,

The quality and detail of your work is just incredible.

I wish I'd never seen the lapdesk you made, actually that's a lie, I'm glad I saw it but I cannot stop looking at the photo's of it, one day I will make one if my skills ever allow it.

Darren.

-

9th February 2016, 08:13 AM #139

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2015

- Location

- Brisbane

- Posts

- 1,149

You are a man of great patience Derek. Beautiful work.

-

1st March 2016, 12:25 PM #140

A little update ... six drawers down.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

1st March 2016, 02:41 PM #141

Member

Member

- Join Date

- Apr 2012

- Location

- Perth hills

- Posts

- 56

Looking good Derek

-

15th March 2016, 12:25 AM #142

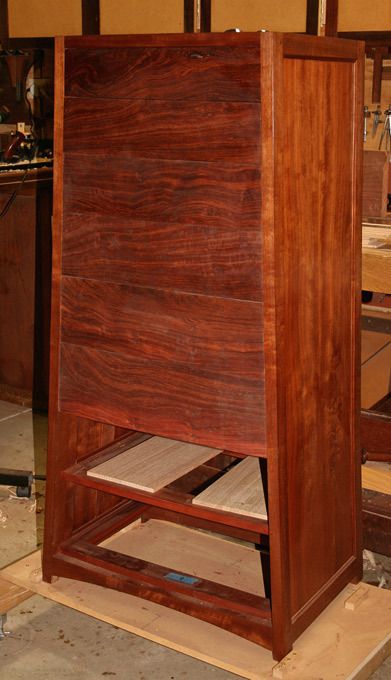

All the drawers are finally done ..

Well, almost ...

The drawer bottoms have still to be made for 4 of the drawers. After making each one separately, it occurred to me that this was the one item that I could build en masse.

After the drawer bottoms are in, the task will be to make the drawer fronts coplanar. They are close to one another in curve, but there are a few variations here-and-there. What I plan to do is shim the drawers by about 1/2" to raise them out an equal amount so that they all lie proud of the carcase, place the chest on its back so that the drawers face upward, and then sand the faces with a long sander made out of a 2x4.

What do you think of this method? Any other ideas?

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th March 2016, 12:51 AM #143

Senior Member

Senior Member

- Join Date

- Oct 2015

- Location

- Perth

- Posts

- 298

They are magnificent. You must be please.

brava

brava brava

brava

-

15th March 2016, 01:50 AM #144

Hi Derek

are you striving too much for perfection?

the "few variations here-and-there" could be seen as the marks left by the artisan, while perfect in curvature and all coplanar could be interpreted as the marks of a machine made item.

my suggestion is to get as close as you can using hand tools but eschew the 4x2 and sandpaper.

I'd only go for a "perfect" front if I was planning on using a high gloss for a mirror like finish.regards from Alberta, Canada

ian

-

15th March 2016, 07:39 AM #145

-

15th March 2016, 09:47 AM #146

Derek, depending on just how large the deviations are, I'd be reaching for a compass plane to do the bulk of the work, which should keep the curves sufficiently even, but allow you to work on any high spots. Unless it is going to be too risky to pane (I note that wild-looking grain!), I would only move to the paper for a bit of final cleaning up. I wouldn't be aiming for +/- micron perfection, but I'd certainly want the top of each front to line up with the bottom of the next. I'd think that's where the eye will detect any errors - with that swirly grain, it would be hard to spot small surface deviations over the rest of the fronts.

Wow, this piece of furniture has presence! Having all the drawers in seems to magnify it - it won't be able to hide in any room it's placed in!

Cheers,IW

-

15th March 2016, 06:43 PM #147

Hi Derek.

I fear that if you lay the unit on its back, then sand, that you may get a little misalignment again when it stood back up. The effort may be in vain. I would leave it upright to fine tune the drawer fronts.

Looking really good.

Well done.

Pete.

-

15th March 2016, 10:52 PM #148

Hi Ian

It will never be perfection. There are too many indications of handplane use, from the dimensioning with jointers, to smoothing, and the scraped mouldings.

As careful as I have been to plane to the line, the drawer fronts have some variations here-and-there. It is enough for me to work on them some more, which I deliberately left to the end since there was no point in trying this earlier. At the beginning of August is the Perth Wood Show, and I usually enter a piece in the furniture competition. I thought that I would enter this piece, if it is completed in time (not sure about that! There is a lot more work to do). I do not stand a chance of winning (my Wegner chair came fourth last time), as handmade cannot compete with the "perfect" machine-made pieces that are entered (and that is a criteria for a good place). The drawers may be acceptable to you and I, but they are too far out for a competition. That is the nature of competition pieces.

The plan now is to use a long sander with a fine grit (600). This will just score the high spots, which I will then plane down. There will still be some variations, but that is fine with me.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th March 2016, 11:05 PM #149

Hi Ian

There is no way I could use a circular plane on these curved drawer fronts (I have a Record #020). The curve is not circular but an ellipse ..

As mentioned above, I shall use a plane. The LN #3 above is used with the chipbreaker, so grain direction is not an issue. I tried to set the chipbreaker on the #020 (I did try it on the hollow side of the bow), but this would not take a shaving.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th March 2016, 11:07 PM #150

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Visit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Lingerie Chest

By derekcohen in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 17Last Post: 30th November 2014, 05:29 PM -

Sea Chest

By LR09WA in forum WOODWORK - GENERALReplies: 14Last Post: 11th June 2011, 08:00 PM -

Ice Chest

By rod1949 in forum Links to: TIMBER & HARDWARE SUPPPLIERSReplies: 1Last Post: 15th September 2004, 08:13 PM -

Chest

By GRS in forum WOODWORK PICSReplies: 8Last Post: 7th July 2004, 12:26 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote