Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 74 of 74

-

17th June 2012, 08:53 PM #61

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

-

17th June 2012 08:53 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

17th June 2012, 09:02 PM #62

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

Micrometer Carriage Stop

Micrometer Carriage Stop

Here are some photos of a micrometer stop I machined up using a Starrett Micrometer head purchased from the USA on E Bay.

A very handy addition to the Hercus 260 lathe.

I use it a lot.

regards

Bruce

-

18th June 2012, 07:50 AM #63

Nice one Bruce.I hadn't seen that cross slide stop before.Simple solution and looks like it mounts to existing holes as well.

Do you find you use the micrometer function much for the saddle stop or is it just used as a simple stop?Cheers from Micheal.

-

18th June 2012, 08:29 AM #64

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

And because I have allowed technology to leave me behind

I rely on the graduated dial on my saddle stop frequently.

I rely on the graduated dial on my saddle stop frequently.

I don't use my vertical milling attacment as frequently as does Bruce, but with the attachment attached the only means of accurate positioning is, for me, the mic stop because the compound slide is absent.

BT

-

18th June 2012, 09:06 AM #65

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

The usual Abratool workmanship.

I notice the absence of drive dogs fitted to the beige No.O spindle nose Bruce. I know you know what you are doing but when I bought my mill it was obvious that the previous owner didn't. It would have taken me a good couple of hours to remove the arbor. I had to make a puller up to pull from the front while giving it a hiding from the rear. Now days I can remove my Morse arbors with a firm tap or two with an aluminium drift. Overtightening drawbars is like overtightening chucks. Not a great practice and one that can result in tears.

Those batteries got enough charge in them for a few indexer photos?

BT

-

18th June 2012, 10:33 AM #66

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

Saddle Stops

Saddle Stops

Micheal

I mainly use the Micrometer stop for Milling with the Hercus Vertical Milling Slide.

Bob has mentioned that without the micometer it is very hard to adjust the saddle accurately.

I also have a standard Hercus Saddle Stop & use it most of the time for turning operations, particularly when using a boring bar. Its very handy to know when approaching the bottom of a blind hole when boring.

Hope all is well in your part of the world, up north.

You should receive the 4MT headstock chuck stop I mailed you, in the next day or so.

My chuck stops are nearing completion. I have made one for the 4" chuck & another design using the 3C collet set up for the larger 6" chuck.

They should make life simpler.

regards

Bruce

-

18th June 2012, 10:53 AM #67

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

Drive Dogs

Drive Dogs

Bob

The Mill came to me in the used condition without the drive dogs.

Its probably a strange thing, but its something I have lived with & not noticed.

I agree with you the drive dogs would be an advantage, I do not know why they were ever removed. I will get to it & make a couple.

The End Mill Head is set up at the moment, so when it comes off, that will be the next job on the"Beige" mill. Its hard to get trousers to match the colour

My Horizontal Mill Arbor 3MT is in very good condition. It grips well. I only nip up the draw bar & do not overtighten., its a good point you have mentioned.

A lot of these mills were in schools & colleges, with "not so careful operators"

Another job I am considering on this mill is to scrape the longitudinal slide, when I get the bigger surface plate, to use, as a reference. I dont think it will be too big of a job.

regards

Bruce

-

18th June 2012, 05:19 PM #68

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

-

18th June 2012, 05:29 PM #69

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

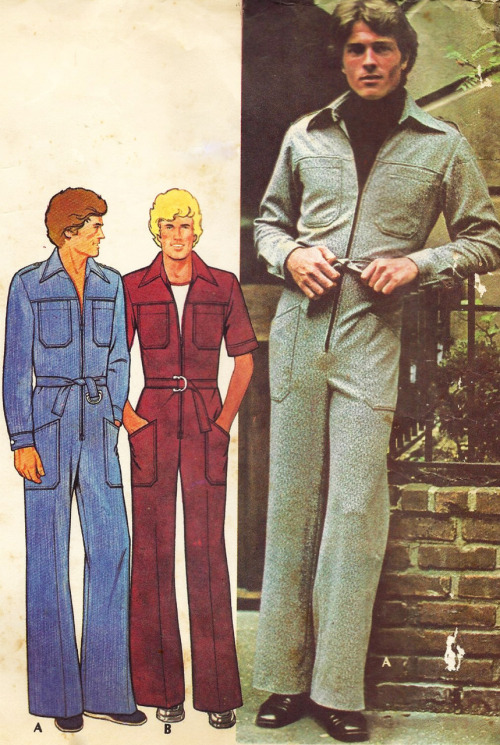

Jump Suits etc

Jump Suits etc

Bob

Thanks for the pictures of the jump suit. There is nothing to get caught in a machine.

It once again gave me a laugh.

I got my wife to have a look at the pictures, & her comment was "Good Grief, where does Bob get those picture from? "

I have no further comment, just dumbstruck I think even my beige mill would get a shock !

I think even my beige mill would get a shock !

Been making the "Chuck Stops" for the past hour or so, they are progressing well, photos will follow.

regards

Bruce

-

18th June 2012, 06:28 PM #70

Just opened my little care package and all looks great thanks Bruce.I suppose I will get on and finish it now.

Bullion transfer is complete .They are very friendly operators in the Cayman Islands.I suppose that is why you bank there.Cheers from Micheal.

-

18th June 2012, 06:57 PM #71

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

Cayman Islands

Cayman Islands

Micheal

Correct, I only wish I had have discovered the Caymans 50 yrs ago.

It would have helped a lot over the years

I have been working on the Chuck stops again today.

These jobs seem to take forever, but it keeps me out of trouble.

I can see the Chuck Stops will offer a lot of advantages, when setting up "Those odd jobs" which continue to occur.

regards

Bruce

-

18th June 2012, 07:14 PM #72

-

18th June 2012, 10:26 PM #73

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2007

- Location

- melbourne australia

- Posts

- 2,645

Returning briefly to the original thread topic

, Bruce made me a couple of his knurled screws for my 260 and they are great. It's good there are people like Bruce in the world, because if it was left to me, jobs like these would stay on the "To Do" list forever.

, Bruce made me a couple of his knurled screws for my 260 and they are great. It's good there are people like Bruce in the world, because if it was left to me, jobs like these would stay on the "To Do" list forever.

Chris

-

18th June 2012, 11:54 PM #74

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

Hey Bruce ,

How about some photos of the back stops. I promise I'll keep my mouth shut about the beige slacks.

BT

Similar Threads

-

Graduated backgrounds

By TTIT in forum PHOTOGRAPHYReplies: 22Last Post: 11th September 2011, 09:09 AM -

Small knurled knob

By Tiger in forum METALWORK FORUMReplies: 10Last Post: 27th April 2010, 12:51 PM -

Knurled nut

By footz in forum THE HERCUS AREAReplies: 21Last Post: 10th October 2008, 07:10 PM -

Looking for Brass knurled knobs

By B.C in forum WOODWORK - GENERALReplies: 17Last Post: 23rd January 2005, 12:58 PM

Likes:

Likes:

Bsmarta..eT

Bsmarta..eT