Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 2 of 2

Thread: A Steady Rest for the Hercus 260

-

24th May 2011, 09:23 PM #1

Cba

Cba

- Join Date

- Aug 2007

- Location

- Melbourne

- Age

- 68

- Posts

- 1,417

A Steady Rest for the Hercus 260

A Steady Rest for the Hercus 260

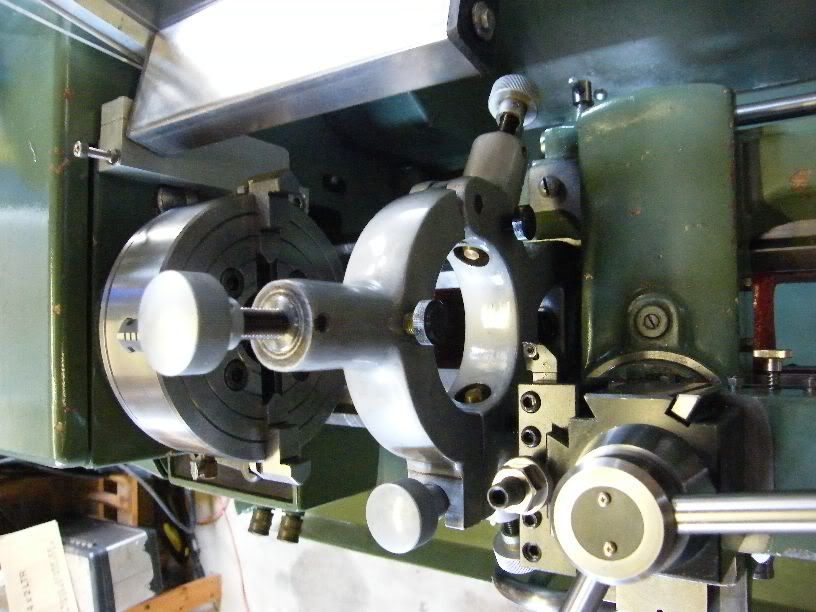

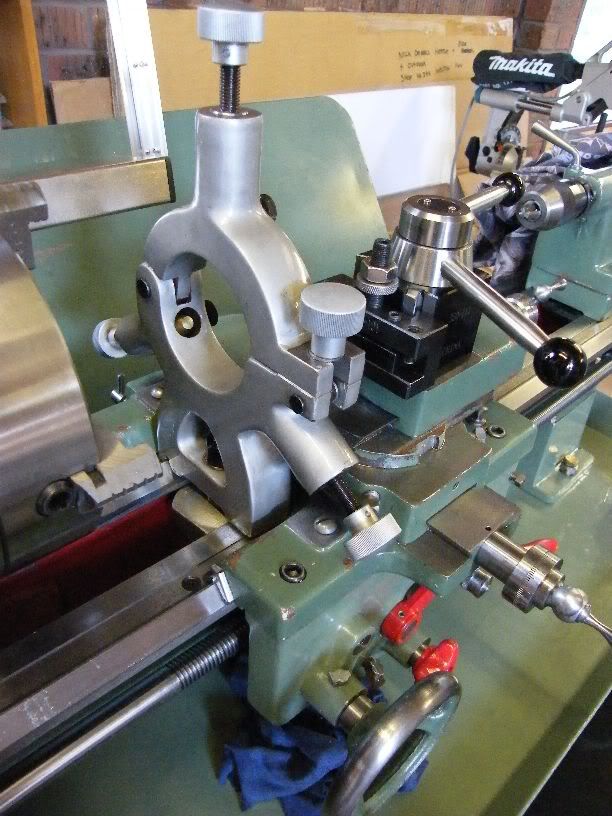

I needed a stedy rest for my Hercus 260. Pre-loved original Hercus steady rests seemed to sell around the $200mark. A lot for a very basic design.with flat fingers. I was then looking at making my own, either from castings or from flat stock. Then I found on eBay a range of brand new steady rests made to fit several US made lathes, and among others also for the Southbend 10K model. Now the Hercus 260 appears to use the same bed profile as the 10K, and it has the samne center height as the 10K. I asked the US seller (tools4cheap), and he was prepared to post it in a low cost USPS flat rate box. I ordered it for US$ 149 plus US$46 postage, total AU$189 (thanks to our good new exchange rate). It arrived exactly 11 days later, and was very well packed indeed. Net weight of the unit is 4.2kg. It was eBay # 140514155133.

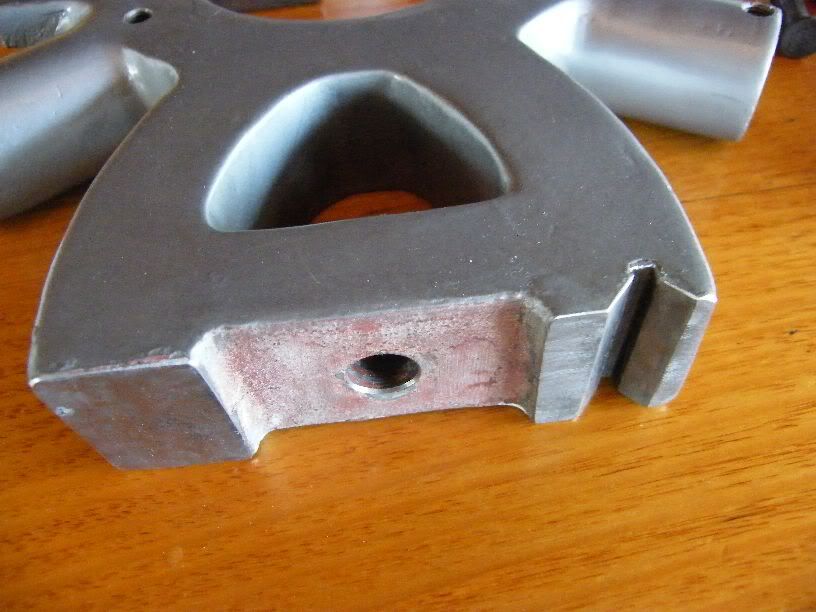

I thought I take some pics. It is made of cast iron, and since all threads are metric I assume it is made in Taiwan or China. The fingers operate very smoothly once degreased, cleaned and deburred. Each of the 3 adjuster screws has two threads. The larger is a right thread, the smaller is a left thread. It takes only 14 revolutions on the finger adjuster knob from fully in to fully out. The fingers can be adjsted and locked without tools, just using the knurled knobs. It is in my opinion a better system than the simpler one originally used by Hercus. The base fits perfectly onto the 260 bed, the wings of the saddle go neatly around this steady rest (from both sides of the saddle that is), and the tool bit can be brought very close. The finger tips are a push fit and are made from what appears to be plain brass (NOT Bronze). The steady rest bore is exactly at center height. It allows for a maximum of 79mm diameter stock to feed through, maybe 78 given the irregular paint thickness. It could be easily bored out by 5mm give 90mm feed through, but it would be pushing going much further. For me it does not matter, since I also have a rotating tailstock chuck to grip pipes from the inside up to 100mm.

See pics, I hope it helps someone deciding if this could be an acceptable alternative to replace that missing or lost original steady rest. The US$ exchange rate is said to come down even further, making purchases from the US more interesting by the day....

-

24th May 2011 09:23 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

25th May 2011, 01:39 AM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2010

- Location

- melbourne, laverton

- Posts

- 1,469

you seem pretty happy with the steady rest. that's great. what are you going to make with it?

goes well with that great looking lathe you have

Similar Threads

-

Hercus 9inch travelling steady castings

By Swarfmaker1 in forum THE HERCUS AREAReplies: 11Last Post: 5th February 2011, 02:10 PM -

Best kind of steady rest

By Tiger in forum WOODTURNING - GENERALReplies: 8Last Post: 8th July 2010, 05:54 AM -

Steady Rest & Vase/weedpot ????

By yaryetnom in forum WOODTURNING - GENERALReplies: 5Last Post: 19th July 2009, 07:03 AM -

Four-Wheel Steady Rest

By joe greiner in forum WOODTURNING - GENERALReplies: 21Last Post: 30th November 2008, 05:21 PM -

Steady

By DonN in forum WOODTURNING - GENERALReplies: 1Last Post: 28th February 2001, 04:31 PM