Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 14 of 14

-

8th July 2009, 12:40 AM #1

Intermediate Member

Intermediate Member

- Join Date

- Mar 2008

- Location

- Tasmania

- Posts

- 29

Broke clean at 160 pounds $2 epoxy

Broke clean at 160 pounds $2 epoxy

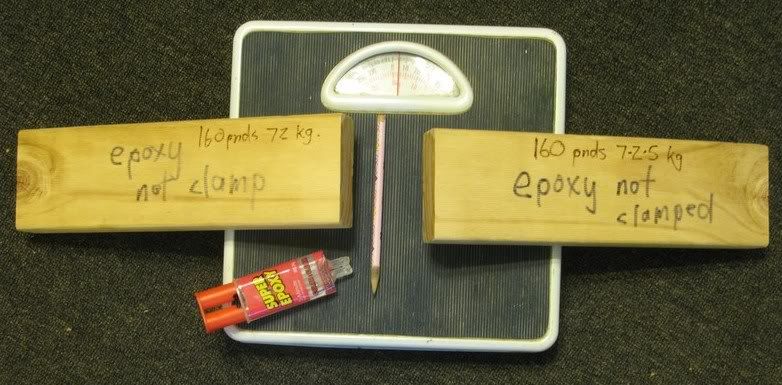

Just for interest I am glueing up some table legs and decided to first test a PVA and epoxy glue. First test was this epoxy I purchased from chickenfeed store for $2. it is 5 minute set time, max strength in 1 hour, glued end to end with nothing else, held by hand for a few minutes, then test weighted, broke clean at 160 pounds, 72.5 kg with feet on both ends and pencil underneath, Tomorrow i will try same with crosslink external PVA glue clamped. Please note scales are out by about 3kg.

Regards Tim

-

8th July 2009 12:40 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th July 2009, 07:20 PM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Feb 2007

- Location

- Adelaide

- Posts

- 595

Interesting Tim. I like practical tests and measurements. I think there are a few variables to be controlled though, if your comparison of epoxy and PVA is to be useful. I am interested in how this kind of test is related to the construction or fabrication of your table legs. Are you end butting sizeable cross-sections end grain to end grain? Also, I wonder if the stressor weight should be reckoned in leverage terms rather than dead weight. A smaller weight at a longer distance could produce the same tear apart stress. Looking forward to hearing about the PVA.

-

9th July 2009, 02:06 AM #3

Intermediate Member

Intermediate Member

- Join Date

- Mar 2008

- Location

- Tasmania

- Posts

- 29

I just did the PVA clamped it broke at 250 pounds plus, it took all my 110kg body weight then I had to put my hands under the table and pull upwards to get it to break 114kg. I was amazed, this glue when clamped is STRONG. It is selleys crosslinked PVA external glue.

Its a pretty rudimentary test but it still gives me a good comparison i can use, I wanted to get a rough idea of the actual strengths and it was easy to do, the non clamped PVA broke at 95 pounds, which was not too bad considering.

My table 125mm rails are housed into the 100mm square legs 15mm but no mortise and tenon joints, thats why i tested the glue, I have more than twice the surface area for the glue than in test for each joint.

Regards Tim

-

9th July 2009, 09:28 AM #4

It would be interesting to see how some real epoxy stands up in the test. That Chickenfeed gear is pure junk, you might as well try spit & sticky tape!

-

9th July 2009, 10:33 AM #5

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

A very interesting test my friend.

Keep it up, put the results in a table ( and write a scientific treatise while you are at it ) and post.

-

10th July 2009, 01:01 PM #6

Intermediate Member

Intermediate Member

- Join Date

- Mar 2008

- Location

- Tasmania

- Posts

- 29

Chickenfeed gear is pure junk

Do you mean there epoxy is junk??

Regards Tim

-

10th July 2009, 04:32 PM #7

yes & yes. lol

-

10th July 2009, 04:36 PM #8

By nature, isn't epoxy a brittle type of compound?

Like glass is strong but brittle; when it does break the molecular bonds are brittle and break apart very easily

The PVA wouldn't be as brittle and would give a lot more flex before snapping.

I find when I try tests like this, all I learn is how well stuff glues your fingers together. Bare foot and still able to count to ten.

Bare foot and still able to count to ten.

-

11th July 2009, 12:04 PM #9

Intermediate Member

Intermediate Member

- Join Date

- Mar 2008

- Location

- Tasmania

- Posts

- 29

Thanks for that, I have some good epiglass 2000 epoxy here also, it is like glass when it sets although it is great for fine cracks gets right into the joint and holds it together.

Regards Tim

-

12th July 2009, 08:07 PM #10

Novice

Novice

- Join Date

- Jul 2009

- Location

- Tasmania

- Posts

- 11

The only time you would use epoxy rather than PVA is when you need a long setup time that exceeds the grab time of the PVA, or when the cured glue will be wet for an extended period. Cross-linked PVAs such as Kleiberit 303 and Titebond 3 will always be adequate for general woodworking, and are waterproof enough to survive the occasional immersion (I have a chopping board glued with Titebond 3 that is washed daily and the glueline shows no signs of failing after 4 years). In all the testing I've done with cross-linked PVAs, the wood has never split at the glue line.

Cleanup is a problem with cross-linked PVAs, and you have to be especially careful when clamping to make sure they don't come in contact with steel clamps. Kleiberit 303 stains blackwood, so finishing prior to glue-up is recommended.

Epoxy comes with a warnings a mile long, so from an OHAS point of view, it should only be used when PVA is just not an option.

-

13th July 2009, 06:31 PM #11

-

13th July 2009, 07:32 PM #12

Nope tittybond3 is a pva!

....................................................................

-

13th July 2009, 08:44 PM #13

-

13th July 2009, 10:45 PM #14

Yeah, I can remember my old man used Araldite to fix anything and everything.

I reckon he used to break stuff just so he had an excuse to mix part a with part b.

Nowadays, you wouldn't want to get the original Araldite mixture on your paws or you'd end up with mushrooms growing from your fingers - all 9 of em Bare foot and still able to count to ten.

Bare foot and still able to count to ten.

Similar Threads

-

What do you clean up epoxy squeeze out with ?

By JDarvall in forum WOODWORK - GENERALReplies: 27Last Post: 26th September 2009, 12:42 AM -

Got any tips for thinning epoxy ? epoxy wash.

By JDarvall in forum MUSICAL INSTRUMENTSReplies: 19Last Post: 23rd June 2008, 10:26 AM -

Epoxy clean up

By mat in forum BOAT BUILDING / REPAIRINGReplies: 9Last Post: 3rd November 2007, 10:46 AM -

Epoxy Clean-up

By onthebeachalone in forum BOAT BUILDING / REPAIRINGReplies: 33Last Post: 22nd August 2006, 01:22 PM -

epoxy clean up

By MathewA in forum WOODWORK - GENERALReplies: 17Last Post: 3rd April 2006, 01:12 AM

Reply With Quote

Reply With Quote