Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 48

-

20th February 2008, 04:12 PM #16

Member

Member

- Join Date

- Jan 2008

- Location

- manila

- Posts

- 50

Boz,

I don't think it is safe since the direction of the blade will throw the material being cut away from the table, dangerous kick back could very well result from it... If you get to work around it, dust will acummulate on the tool shortening its lifespan. so it really isn't recommended.

-

20th February 2008 04:12 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

20th February 2008, 04:18 PM #17

-

21st February 2008, 07:40 PM #18

Member

Member

- Join Date

- Jan 2008

- Location

- manila

- Posts

- 50

here, i adjusted the guide for my final cuts to bore through... hehehe, the double tape let go, hence the slight offshoot. but thats ok, it wont do any damage.

test fit... hmmmm perfect

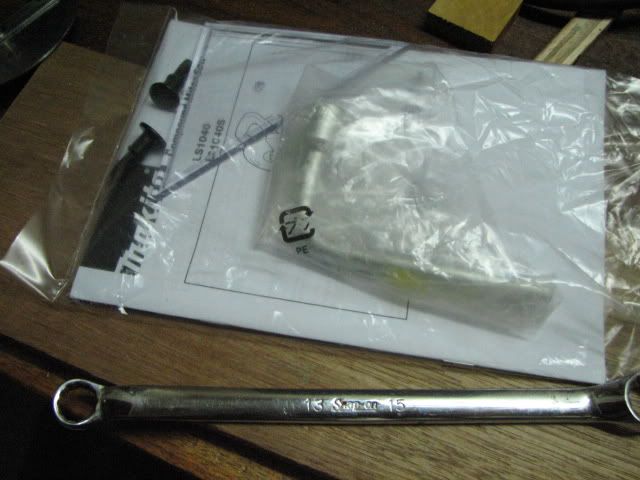

bought bolts for my router table's use...

now, drilling the pilot holes to be sure lang...

drilling a bigger hole to accomodate the threaded screw catch and attaching them...

there will be a slight protrution as the MDF moved upward a bit...

nothing that a little sanding cannot fix...

installed a bolt to check for flatness...

and its in great shape. a very slight difference that a calling card spacer will correct...

next will be the table that I will convert to accommodate the whole top... till then...

work progress is slow, but its moving... hope I can make it as nice as thoase posted earlier...

-

21st February 2008, 08:23 PM #19

Member

Member

- Join Date

- Jan 2008

- Location

- Sunshine Coast, Qld

- Posts

- 82

In response to BozInOz . . . to keep the saw on, I put a bit of shaped timber in the trigger space to hold the trigger on and turn the saw on and off at a switch on a power board. The power saw is about 20 years old, has spent about 10years up side down, still going strong and has more than paid for itself. The saw must have been made on a Wednesday? A bit of wood will jam or kickback just as easily on my table as it will on a Triton or a $100K table saw at a joinery shop - it all depends on the operator. I choose to use it as I have many hours experience on a saw as a cabinetmaker (in a previous job), am aware of the dangers and manage the risks - Oh yes ... and I'm also a tighta---e. The advantage of a Triton over mine is that you can switch the machine off faster after you have cut your fingers off

. Back to being serious . . . I wouldn't recommend using a saw upside down or a router/saw table like it, no it's not safe and it is just an example of a router table - as requested. Cheers, BRD (still with 10 fingers

. Back to being serious . . . I wouldn't recommend using a saw upside down or a router/saw table like it, no it's not safe and it is just an example of a router table - as requested. Cheers, BRD (still with 10 fingers  touch wood. No I said wood - not the sharp metal spinning thingy

touch wood. No I said wood - not the sharp metal spinning thingy )

)

-

22nd February 2008, 03:38 AM #20

Member

Member

- Join Date

- Jan 2008

- Location

- manila

- Posts

- 50

BRD,

I dont have a table saw and been wanting one. A makita rep told me that a circular saw isn't advisable in that configuration. but with your experience, I just might consider it... thanks...

cheers

-

22nd February 2008, 09:27 AM #21

-

22nd February 2008, 09:44 AM #22

Wongo,

Is that a Triton lurking under that table? Cheers,

Cheers,

Bob

-

22nd February 2008, 03:00 PM #23

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Feb 2008

- Location

- Peakhurst

- Age

- 67

- Posts

- 1,173

Boz,

Yes you can put a circular saw upside down. It does work just have to watch out for kickback. To keep the switch on use a large cable tie. Just remember that saws have teeth and anything with teeth that hard will eat meet. Even my 12 inch TS got me (due to my lapse in concentration). Check out the avatar.

Recomendation is by a TS as circular saws really don't have the grunt to be used as a TS.

The Bleeder

-

22nd February 2008, 03:53 PM #24

-

22nd February 2008, 04:15 PM #25

Horizontal router table

Horizontal router table

There is a Horizontal Router Table which was easily made for an application one day.

This simple addition to my trusty old table saw can be seen at

http://gallery.groov-e.com

under machinery.

Regards Mike

-

22nd February 2008, 04:25 PM #26

-

23rd February 2008, 03:30 AM #27

Novice

Novice

- Join Date

- Feb 2008

- Location

- Malaysia

- Posts

- 10

Bleeder, that is just so nasty. How long was the operation. and hows the finger? Any advice to us newbies before we start ripping our fingers off?

-

25th February 2008, 06:35 AM #28

Member

Member

- Join Date

- Jan 2008

- Location

- manila

- Posts

- 50

fitted my old drawing table with MDF for extra backing for the router area...

I'm now at the process of building my fence...

now, I'm contemplating on a split fence. is there a big difference in having a split fence as against a fixed one??? advice needed.

TIA

-

25th February 2008, 07:56 AM #29

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Feb 2008

- Location

- Peakhurst

- Age

- 67

- Posts

- 1,173

Rickster,

Still got the finger (happend 6 years ago). 18 months of no wood work though while the physios did their job.

TS's are dangerous enough. Turning a circular saw upside down is more of a reciepe for disaster. With a TS the blade slot is narrow (only just wider than the blade it's self) but on a circular saw the slot is rather wide, this allows for mitre cuts. Unless you put a plate in (and there are no guarantees that it is going to stay there) ripping small width timber is a no..no.

Use a circular saw for what is was designed for and buy a TS for ripping down or remilling timber.

Advice, read all the safety instructions you can. Remember the one that tells you 'keep you fingers away from the blade'. When ripping timber don't rush, concentrate on what you are doing. Do one job at a time and do it well and not 10 jobs at a time and do them badly.

Steve

-

25th February 2008, 04:11 PM #30

Thought I'd combine the circular saw stuff and then put in an answer (despite this being a router thread.)

As Cliff said, that is the basis behind the Triton Workcentre

Under there, you mount your circular saw. People have been using it successfully that way for years.

A. Triton's solution is a velcro strap. Has the advantage of being able to release it once you are done for the day.

B. So how does a 3.25HP (2400W) circular saw not have enough grunt, when a Jet is happily operating at 1.75HP? They are at least comparable, if not exceeded by the big CS.

With all due respect to you and your finger Steve, there are right ways and wrong ways of doing things.

Mounting a CS upside down can be (and has been done for a long time) a perfectly safe, and reasonable solution. There is certainly a wrong way of doing it as well, but how come there seems to be a concerted effort to ignore how it has been done successfully in the past, and every post that others (such as Cliff) has made that there is a commercial solution that does just that? Sorry to be on the Triton bandwagon here, but generalised comments that it can't be done isn't exactly correct.

Now I am mindful that this is turning into a hijack of a router thread, so let get back to mounting routers under tables (and yes, that can be done safely without having to buy a spindle moulder)."Clear, Ease Springs"

www.Stu's Shed.com

Similar Threads

-

Critique pictures. Read 1st post

By RETIRED in forum WOODTURNING - GENERALReplies: 377Last Post: 21st November 2012, 07:27 AM -

How to embed pictures in a post?

By Caveman in forum WOODTURNING - GENERALReplies: 9Last Post: 21st January 2008, 07:20 AM -

Re-sizing pictures to post on this forum

By Ian Smith in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 6Last Post: 27th October 2006, 10:50 PM -

Another router table post

By Grizz in forum ROUTING FORUMReplies: 10Last Post: 20th October 2006, 05:49 AM

Reply With Quote

Reply With Quote