Needs Pictures: 0

Needs Pictures: 0

Results 1 to 15 of 42

-

20th January 2016, 08:29 PM #1

The bench-bench that got a bit carried away...

The bench-bench that got a bit carried away...

This has to be one of the longest projects, from gestation to finish, that I've done, & that's saying something! I've been thinking about it long before I cut the wood from a windfall Forest Redgum, which was in 2010, as the dates written on the painted ends of the chunks told me.

Ever since I first saw a "bench bench", I've been taken with the idea and spent a lot of time thinking about what features one should have to best suit me. One job I wanted it to do was to hold boards up high for dovetailing & cutting tenons. A while back, I made a "Moxon" vise to do that. It was handy, but suffered from two shortcomings, 1) it didn't sit quite high enough to suit me and 2) it wasn't wide enough between the screws. I wanted to be able to get at least a 600mm wide board in it.

Then a couple of years ago, I realised my 'portable bench' wasn't so portable now I'm getting on a bit, so I started thinking about how I could pack all this into a small auxillary bench & have the best of all worlds. After much thinking and several false starts, this is what I've come up with:

Aux bench 2.jpg

But it's not a one-trick pony; turn it about & this is what you get: Aux bench.jpg a small bench complete with front & tail vise!

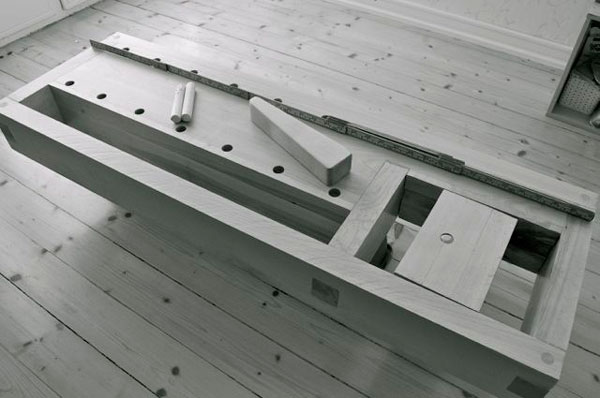

You can see the general layout underneath in this pic:

Bench under.jpg

I was going to do a WIP, but the job stretched over such a long time & I worked at it so spasmodically that too many steps went undocumented. In any case, there's nought much that hasn't been covered in other threads by various members. The only bit that might provide some interest is the front vise, which is my first (& possibly only!) all-wood effort, if you don't count tail vises:

Front vise parts.jpg

The screw is attached to the front jaw (which is lined with a thin piece of Jacaranda for better grip) with a 'garter' that is retained by a She-oak cap:

vise screw & garter.jpg

I've only seen one other all-wood vise, it was very old, pre-1900s, and had had a lot of use, but was still functioning 100 years after it was made, so I'm optimistic mine will go at least half that distance. It's basically the same as the front vise I made about 30 years ago using 1/2" water pipe for the guides (I got the idea for it from somewhere, but can't remember where), which has served me extremely well. Anyway, I've made the wooden guides the same diameter as 1/2" pipe, so if they do fail, it will be easy enough to substitute. However, I reckon you would have to abuse the vise pretty severely to bust the guides - 22mm thick She-oak dowels are pretty tough customers!

I still have to make one last decision. I want to put it on a set of legs, so it can become my new portable bench, but can't decide whether to make the legs high, so that it sits at the same height as on the main bench, or whether to make it lower when sitting on its own undercarriage. It will get most use in the shed as a high bench, and I will only need it to be my 'normal' bench height when it is being used elsewhere, which isn't so often these days. So atm, I'm leaning to high legs, but I haven't cut them to length just yet......

Cheers,IW

-

20th January 2016 08:29 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

20th January 2016, 08:38 PM #2

Looks good Ian, Having the extra height I see as a big advantage for delicate precision work.

-

20th January 2016, 11:16 PM #3

Awesome work Ian. I still aspire to something similar one day

Dave TTC

Turning Wood Into Art

-

21st January 2016, 04:00 AM #4

Great looking "little" bench.

You'll have to build a second one and get Andy to help you do a AWR write up.

Legs?

what you've built will be very light when sitting on longish legs -- and bracing the legs to prevent racking will likely be a challenge.

my suggestion is to use very short legs so when it's sitting on your main bench the surface is at the "right" height for detailed work.Last edited by ian; 21st January 2016 at 04:01 AM. Reason: spelling -- "detailed" works much better in the context than "derailed"

regards from Alberta, Canada

ian

-

21st January 2016, 07:41 AM #5

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Brilliant job Ian!!!

I think the shot of the underside is the most informative shot as it shows the layout so clearly.

I am going to make a Moxon vive. Just wondering about your's not being wide enough. Do you think

700 between the screws is too much to ask?? I do have some very hard and heavy stair treads that

I can use for jaws so flexing should not be a problem.

-

21st January 2016, 08:33 AM #6

Artme, I think 700mm should cover pretty much anything you are likely to cut dovetails across. I don't see any major problems if your chunk of wood will take it without flexing. And old stair tread should do it, they are usually around 38mm thick & pretty solid. As it happens, I used scraps of Merbau stair tread material for my first effort: d_tail vise.jpg

It has about 450mm (can't remember exactly what it was) between the screws but the jaw is plenty strong enough & would have tolerated being wider, and it would've been if my scraps had been longer! . Merbau taps easily and makes a beautiful internal thread, too, I discovered.

. Merbau taps easily and makes a beautiful internal thread, too, I discovered.

Apart from the width being a bit skimpy on the first one I made, my main mistake was not giving it a big enough footprint, so it wasn't as stable as I'd have liked, when clamped between bench dogs. I solved that when I had one of my rare lightbulb moments and cut a pocket in each end for the dogs to snug into - after that it was quite solid. It went to a new home a few months ago, and has had a bit of use by its new owner - maybe he can comment on other potential improvements to the design...

Cheers,IW

-

21st January 2016, 09:16 AM #7

Ian, the number of projects I have set myself this year already exceeds my capacity to finish them by at least 200%!

It doesn't need legs in its 'bench-bench' role, it's designed to sit on its aprons on my regular bench, which makes the surface 150mm higher, and what I reckoned would be just right for the purpose. Even without the bench dogs holding it, it has little desire to move!

Maybe it's not quite as light as you might think! Bluegum is solid stuff (density ~1), and in fact, it is heavier than I initially planned, thanks to my design becoming more ambitious as it evolved. It has ended up more than half the weight of the top of my current 'portable' bench (which is plenty heavy enough for occasional use), and more than ideal if it were to be used only as a bench bench. To satisfy my own curiosity, I'll try to get a weight today, if the bathroom scales will cooperate (& 'er indoors looks the other way long enough for me to sneak them down to the shed ).

).

However, you are quite right to be concerned about its stability on legs, and it's the reason I'm hesitating. Apart from the height, it's the smallish footprint (it will be about 900 x 500) that I'm worried about. The legs will have a foot piece that is at least as long as the width of the bench, so I hope that will give it enough back & forth stability. And be aware, this is not intended to be a bench for heavy planing of hardwood bench parts, just a handy thing I can still move by myself, so there are compromises to be made.

Wracking shouldn't be a problem, I hope. It will have wide stretchers with stub tenons pulled into the legs by 6" drawer-bolts. This system is easy & quick to assemble/disassemble and has worked very well on my main bench for 30 years of heavy use.....

Cheers,IW

-

21st January 2016, 01:10 PM #8

Ok, all sweet, I snuck the scales out, & the top is 45.4Kg. I would've liked it to be a bit less, but I suppose if it's going to be used on its own as an occasional bench, the more weight the merrier. I might have to invest in one of those wheel-about cranes when I become a bit more decrepit.

The undercarriage will probably come to at least half or more of the top weight, so all-up, it's not going to be a featherweight when posing as a bench! ...

Cheers,IW

-

21st January 2016, 02:14 PM #9

Hi Ian

I've seen a photo of a similarly sized small bench that Leonard Lee (Lee Valley Tools) had in an alcove in his office. The mass of that bench was in the base -- which was constructed more like a cabinet than a traditional stretchered frame.regards from Alberta, Canada

ian

-

21st January 2016, 08:32 PM #10

-

21st January 2016, 09:03 PM #11

cool bench

I've wanted something similar so I could sit at it and do small work whilst hanging about waiting for my son to finish training

couldn't think of how to accomplish it without making it too big to fit in the boot of the car regards

regards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

21st January 2016, 10:35 PM #12

Not wishing to take anything away from Ian's brilliant little bench, at about 800 x 200, the Milkman's bench is another alternative for transporting in a car

more info here The Milkman's Workbench Build - Part 1 — Gunpowder Woodworks

there's also a variant that uses wedges to hold the work rather screw vises

link Milkman's Workbench with Wedge Vises - by pinebox @ LumberJocks.com ~ woodworking community

and

Link ‘Milkman’s Workbench’ Without Screws - Popular Woodworking Magazineregards from Alberta, Canada

ian

-

21st January 2016, 11:10 PM #13

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

A bench bench!! This is a truly awesome original idea. I've seen a "moxon" with the tabletop thing happening behind it, which is a slick idea, but to have an entire mini bench on the opposite side is absolutely brilliant!

Perhaps you could come up with a semi-collapsible but still stable design for an undercarriage? Maybe something with legs that cross like scissors and have indexed slots which would allow them to position the bench at variable heights. This could accommodate planing at typical bench height and with a broader splay between the legs, and then pop up to "moxon" height for joinery work? It would take some finagling to get it stable, but I'm sure you could pull it off.

Guilty. I totally understand that for something like a sea chest/blanket box it would be useful to have it wider, but I absolutely love the thing. I use it as a height booster for any and all dovetailing, regardless of width, and I've also used it in a "wracked mode" for holding asymmetrical drawers for planing down the dovetails on the sides, and they didn't slip a bit. It fits perfectly in my end vise (which is, admittedly, a carbon copy of Ian's) and doesn't rattle at all. I could see myself making a wider one one day, but it would mostly be out of desire for a cool project moreso than necessity.

-

22nd January 2016, 08:50 AM #14

Thanks Ian

It was the milkman's bench I had in mind but I still needed something to rigidly support it while seated in my camp chairregards

Nick

veni, vidi, tornavi

Without wood it's just ...

-

22nd January 2016, 09:26 AM #15

I've had this one on my potential projects list for some time.

I like Phil Lowe's argument for a single vise bench that can be worked on from all sides and it seems to me that a small squarish benchtop bench would really only need one vise for similar reasons. I've been unsuccessful in arranging my current workshop area to conveniently have a free standing bench, so it has to unfortunately live against a wall and I appreciate the functionality of my tail vise (actually wagon style) there.

Ian's bench certainly offers both options with not much effort to change between functions. I'd be interested to know down the track which orientation of the bench eventually gets used the most.

Similar Threads

-

1951 Bench Plans - Cabinet Bench and Tool Cupboard

By chrrris in forum THE WORK BENCHReplies: 2Last Post: 5th June 2014, 09:00 AM -

1942 Bench Plans - Bench and Work Table

By chrrris in forum THE WORK BENCHReplies: 3Last Post: 8th May 2014, 08:27 PM -

1943 Bench Plans - Bench Hook and Ideal Bench

By chrrris in forum THE WORK BENCHReplies: 9Last Post: 7th May 2014, 11:49 AM -

Carba tec bench jointer on Mobile work bench

By STAR in forum WOODWORK - GENERALReplies: 4Last Post: 22nd August 2011, 03:24 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote