Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 13 of 13

-

18th March 2013, 08:26 PM #1

New Member

New Member

- Join Date

- Feb 2013

- Location

- new Zealand

- Posts

- 6

Build of the Jack Adjustable Bench

Build of the Jack Adjustable Bench

Hi Guys

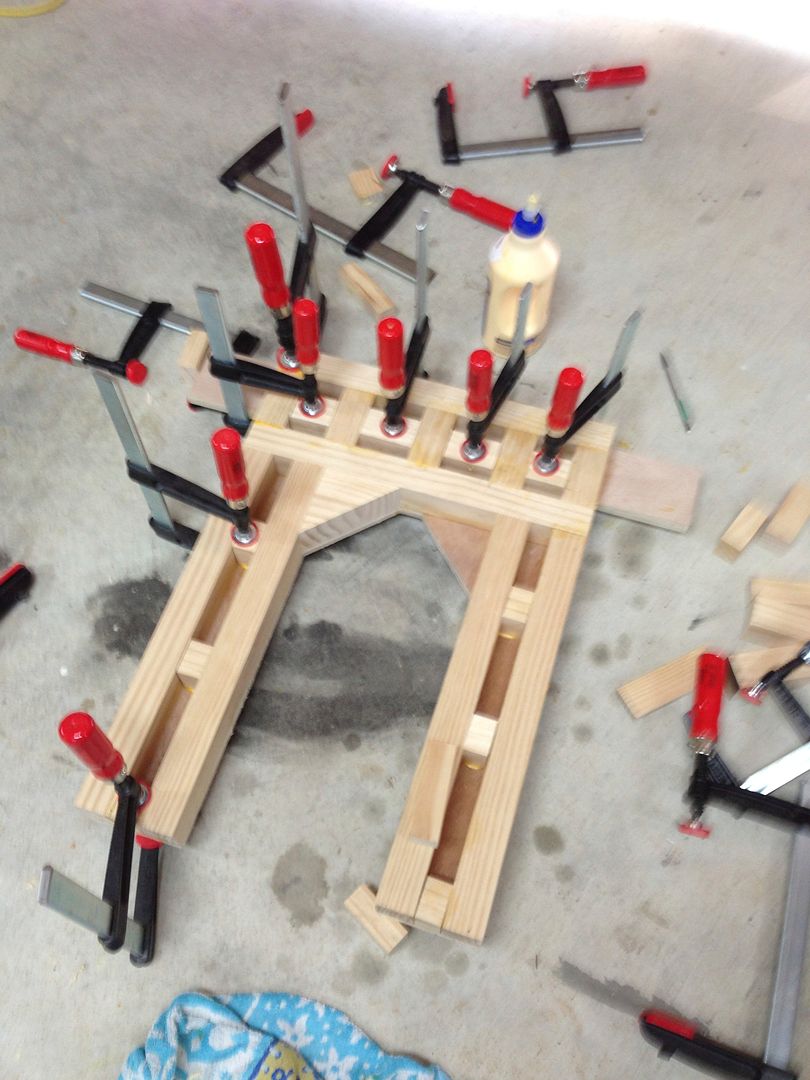

I thought I would post up some pics of the Adjustable "Jack Bench that I have been building. I am fairly new to woodworking and haven't a bench at all hence all my glueing and clamping has to be done on the floor.

I have completed the basic structure so now all I have to do is laminate the bench top and install some vices, then I can get off the floor.

A video of how the bench operate is on youtube here Workbench Design Idea and Plans - YouTube

The bench is basically a collection of Torsion boxes that you construct the Bottom Half/lower legs and the top half/upper legs. It uses 2 x scissor jacks one to control the height and the second to lower the mobile cart so the bench can be moved around the shop. As i have to share my workshop with cars, I wanted a solid bench that was able to be moved around the shop. With the adjustable height I can use it as a outfeed table for my saw bench as well.. Enough talk time post some pics.

[IMG] [/IMG]

[/IMG]

The boxes are sandwiched between two sheets of ply

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

Some of the Torsion boxes finished waiting assembly

[IMG]

[/IMG]

[/IMG]

Test fitting the outer and inner legs

[IMG] [/IMG]

[/IMG]

Pipe clamps and scissor jack installed now to laminate a top

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

-

18th March 2013 08:26 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

25th March 2013, 08:24 PM #2

New Member

New Member

- Join Date

- Feb 2013

- Location

- new Zealand

- Posts

- 6

Just a quick update. Spent the weekend laminating the bench top. Planing more planing and then some even more planing to get the top flat and even. This is the first time that I have attempted anything like this and in hindsight I would have done it differently but the end result is not to bad. I have read on the forums how therapeutic planing with a super sharp plane can be, I must agree, I have a new appreciation for my super sharp planes.

I just have to install my old reconditioned Record 52 1/2" vice and the Veritas Twin Screw Vice, but have just found out that the Veritas is out of stock in New Zealand and are not due into stock for at least another 4 weeks.

[IMG] [/IMG]

[/IMG]

-

25th March 2013, 09:43 PM #3

The bench is looking great.

Shame about the vice. Would it be worth it to get one shipped from West Island?

Shame about the vice. Would it be worth it to get one shipped from West Island?

-

26th March 2013, 08:50 AM #4

Skwair2rownd

Skwair2rownd

- Join Date

- Nov 2007

- Location

- Dundowran Beach

- Age

- 76

- Posts

- 19,922

Looking really good!!

I like the design and ideas behind that bench.

I suppose it's possible to make it longer?

-

26th March 2013, 02:32 PM #5

New Member

New Member

- Join Date

- Feb 2013

- Location

- new Zealand

- Posts

- 6

-

26th March 2013, 08:05 PM #6

That's a very quick build. At least compared to me.

-

26th March 2013, 08:52 PM #7

Junior Senior Member

Junior Senior Member

- Join Date

- Dec 2008

- Location

- Adelaide, SA

- Posts

- 962

Build of the Jack Adjustable Bench

Build of the Jack Adjustable Bench

Interested to hear how u like it. I started building one before deciding on a traditional bench.

I still have the plans and the work that I'd already started.

-

26th March 2013, 10:08 PM #8

I am sorry Kiwipip......that bench is too nice for the workshop!!! I think that it is apiece of furniture that should be housed in the living room!!!

But seriously that is a very well made and finished job.

I have a traditional bench with set height and tool drawer storage under. A mate who is a mechanic got onto some hospital beds that have hydraulic lift of about 400mm. He thought that it would be handy as he watched me many a time put white board cupboards together on a office desk with a larger loose sheet of MDF. It was handy for cupboards but a little low for assembling timber doors. Just to please him (as I was not convinced that the bed would work out) I put a sheet of MDF on the hospital bed and.....very happy with it. The adjust ability is really good and with castors... it worked out to be good system. For bench work though, for vices etc the traditional bench is hard to go past but you have turned my 2 ideas into one very good unitJust do it!

Kind regards Rod

-

26th March 2013, 10:53 PM #9

New to wood working? You could have fooled me! There's obviously a carry over of talent from other disciplines - looky all those green drawers full of tools.

Great job mate!

-

28th March 2013, 08:10 PM #10

New Member

New Member

- Join Date

- Feb 2013

- Location

- new Zealand

- Posts

- 6

Okay I have all but finished or at least as much as I can do.. Apparently there is a 4 week wait for my Veritas twin screw vice. If I wait it will be NZD $425 but if I bring it in from the states it will land owing me just over NZD $600.... I think I will wait.. Lucky for me the other vice an old English record I bought at a junk shop for $20, after a strip down and paint it is as good as new and will offset the cost on the twin screw.

I have predrilled the end and made the vice jaw so hopefully all the holes are in the right place. Once the end vice is installed I will put the dog holes in the bench and vice.

I didnt want to put coach bolts thru the top for the Vice (I didnt have anything to make plugs to cover for the bolt holes) so I made the spacer blocks for the vice countersunk glued and screwed to the underside and then screwed in Lag bolts and nuts to hold the vice on.[IMG] [/IMG]

[/IMG]

My Recond Junk store vice

[IMG] [/IMG]

[/IMG]

Just some images of the finished product

[IMG] [/IMG]

[/IMG]

I know there were some concerns regarding the stability of this bench. This thing is one heavy beast. I have tried it over all the varying heights, once this is set and the pipe clamps tightened its not going anywhere. Yet when you lower the lower cart it is really easy to roll it around my garage.

I know its not your traditional bench but as explained I'm fairly new to the woodworking hobby and was looking for a bench that I can use for a lot of things, sometimes I like to be seated while mucking around or sometimes I want it to be high like a pub bar, and I feel this will be great for a multitude of tasks.

In summary I found the build great and the plans that came for the bench were very detailed and precise, the only pain was getting my head around 1 5/8" and 13/16" imperial measurements. I pre cut all my ply etc so it became like a meccano set in the final assembly. The big limiting factor was the amount of F clamps I had available as to how fast I could build it. If I had to laminate the top again I would use (I think they are called Dominos) to keep the boards in line and saved me a whole heap of time in the planing stage. The most valuable lesson I have learnt is how a very sharp tool (Chisels and planes) is your best friend. I purchased a Work Sharp sharpener and wow what a difference I now have no hair on my arm from shaving them with the chisels after I sharpened them to test them

-

28th March 2013, 09:15 PM #11

Junior Senior Member

Junior Senior Member

- Join Date

- Dec 2008

- Location

- Adelaide, SA

- Posts

- 962

Build of the Jack Adjustable Bench

Build of the Jack Adjustable Bench

Nice work. Maybe I might finish mine also. Not sure if I missed it or not, but what timber did u use for the top?

-

29th March 2013, 04:18 AM #12

New Member

New Member

- Join Date

- Aug 2011

- Location

- Fridley, Minnesota USA

- Age

- 67

- Posts

- 6

Great Job on the Jack Bench!!

Great Job on the Jack Bench!!

I am very happy to hear that the plans worked out for you. You did a great job on your bench. It looks fantastic, and I will definitely put pictures of it on my website!

Which method did you use to flatten the top?

Thanks for posting about your bench,

Charlie Kocourek

(Jack Bench Designer)

-

29th March 2013, 06:16 AM #13

New Member

New Member

- Join Date

- Feb 2013

- Location

- new Zealand

- Posts

- 6

Similar Threads

-

Electric jack suitable for router lift or jack bench

By Woodwould in forum WOODWORK - GENERALReplies: 4Last Post: 25th August 2011, 07:03 PM -

Jack-Bench?

By johnredl in forum THE WORK BENCHReplies: 11Last Post: 5th August 2011, 01:11 PM -

Bench - big, solid, cheap, no tools, no bench to build on

By Clinton1 in forum THE WORK BENCHReplies: 84Last Post: 17th June 2010, 11:16 PM -

Height adjustable bench/horses?

By kaharoa in forum JAPANESE HAND TOOLSReplies: 3Last Post: 29th September 2009, 12:25 PM -

Height adjustable work bench on Ebay

By rhancock in forum WOODWORK - GENERALReplies: 3Last Post: 12th June 2009, 09:30 PM

Likes:

Likes:

Reply With Quote

Reply With Quote