Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 12 of 12

Thread: Cabinet Door Conundrum

-

7th April 2016, 06:14 PM #1

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Cabinet Door Conundrum

Cabinet Door Conundrum

I have a bit of a design issue with which I’m hoping to get some help. Long post here… Sorry.

I recently made a cabinet to go under my workbench. Initially, my plan was for it to just have four drawers the fronts of which sit flush with the front of the carcase. The whole thing would be 640mm wide and 390mm tall, with a 17mm thick River Red Gum carcase and Silky Oak fronts. All went well, and it ended up looking like this:

IMG_0253.jpg

But around the time I was fitting the drawers, it occurred to me that I could take it one step further and build recessed, box-style cabinet doors on the front which would further limit airflow, provide some vertical tool storage in the door itself, and allow me to put a lock onto the cabinet, which I think seems like a good idea given that my shop is under my house and not enclosed.

So I did my usual thing I do where I lose sleep and make my girlfriend angry by being off in la la land instead of listening when she’s talking or, as I like to call it, “my design process”. I’ve determined that the best option MAY be for me to have one wide door instead of two. This is for two practical purposes:

1.) Because of how I’ve designed and built it with no overhang on top or bottom, if I have two doors with a traditional lock in the middle, it will be very difficult for me to attach a mechanism with which to secure one door so that the other locks into it. I would end up with two doors which were bound in the middle by a lock but still would flex outward if you pulled on them. It wouldn’t feel, function, or look like a solid, locked door and would just bother me to no end.

2.) Because of the size of this cabinet, two smaller doors would limit the available space for vertical tool storage. If I had one large door then I could fit larger saws (bowsaw, tenon saw, carcase saw) in it horizontally.

But this comes with its own set of problems…

First, I’m concerned about the hinges sagging or outright breaking. By the time I make the thing out of red gum frame and silky oak panels and then add several saws and other tools to the weight, it’s going to weigh ten or more kilos. I was thinking I could just use several fairly heavy hinges and long screws and just be overkill about it. Does anyone see this being a significant issue? I would use a hasp and staple lock mechanism on one end of the carcase if anyone is curious about how the lock fits in. All brass.

But the number one issue is the way it’s going to look. I can’t, for the life of me, find a typical frame and panel cabinet door online anywhere that is this “landscape” profile, and I’m really worried that it’s going to just look awkward and poorly designed, or, even worse, like I was trying to go for some kind of modern/contemporary look, which is NOT my goal.

A couple of things have crossed my mind as possibilities…

1.) I do a double frame and panel construction with a bookmatch like the back of the cabinet, which looks like this:

IMG_0254.jpg

This is all well and good, but it has the downfall of putting the frame piece on the inside of the cabinet, which could be awkward to work around when installing vertical tool storage mechanisms.

2. I do a glued, bookmatched panel in the front. This creates some symmetry in the door, which sort of plays a trick on the eyes and creates an “at a glance” illusion of two doors, which looks less awkward.

3. A series of chamfered boards running vertically as my panel.

Or 4. Some kind of symmetrical moulding which possibly comes to some kind of peak in the middle of the front and works in the same was as 2. above, which is to create the illusion of two doors when there is only one.

Or maybe I’m just being super bored at work and overthinking all of this…

Interested in feedback on anything that was said here, particularly the hinge integrity problem and the awkward design problem.

Thanks a lot in advance, and thanks in arrears if you actually read this entire post.

Cheers,

Luke

-

7th April 2016 06:14 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

7th April 2016, 08:17 PM #2

Perhaps a drop down or lift up cover would work.

You couldn't work with it open, but perhaps that's no a bad thing. You could still make it as deep as you need to hold a saw till though.

I'm thinking something like this rotated through 90degrees.

https://lh4.googleusercontent.com/-O...0/img_4235.jpg

-

7th April 2016, 08:24 PM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

You're onto something here. I could do a drop down with a chain that hangs horizontally when open.

My initial worry with this would be that the chain would catch when I tried to close the door. Perhaps there is a solution. I'll give it some thought...

Another downside of this would be the fact that it would have to be latched to be closed, and reaching up on top of it in order to do that is awkward what with the overhang of my bench.

Still worth thinking about.

Thanks!

Luke

-

8th April 2016, 05:01 PM #4

Hi Luke

Piano hinges would work and will support a considerable load.

however, I think ya mad !

If that lovely chest needs security protection, build a case that it can slip into -- I'm thinking of the cases used to protect campaign furniture when it was on the move. I'll let you google the concept.

If you go this route, the saw till will be part of the protective case and could be made to separate from the rest -- with the added advantage that you could fit a proper mortice lock.regards from Alberta, Canada

ian

-

8th April 2016, 05:12 PM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Ian,

Why's that? Which part is mad? Doing it with one door?

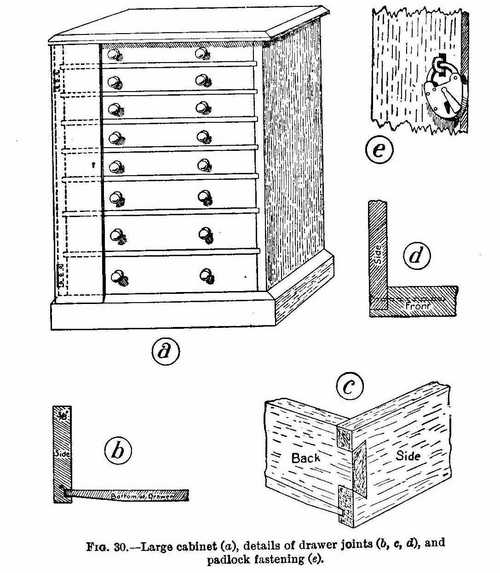

To clarify my end, I'm talking about something like this:

cab_opener.jpg

Only one wide, squat door instead of two. I would likely use a fielded and beveled frame and panel construction for the front, possibly with moulding.

Cheers for the feedback.

Luke

-

8th April 2016, 05:18 PM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

A couple of things to remember are that this is under my workbench, and also weighs a TON...

I'll do a bit more research on the casework for campaign furniture you're talking about, but moving the cabinet into and out of a case for security isn't really an option I'm afraid.

-

9th April 2016, 01:08 AM #7

Because you've built a very nice chest of drawers

which no doubt displays your skill at dovetailing and fitting piston-fit drawers.

But now you seem to be saying, "I really should have built something more like this"

cab_opener.jpg

As I see it, your options are limited:

1. you can give the current chest away and start from scratch -- perhaps the existing chest is not too big to use inside the house?

2. you can build a new carcass to fit the drawers in the existing chest -- but it will be difficult to achieve as fine a fit building a carcass around the drawers, rather than the drawers to fit the carcass.

3. you can extend the exiting carcass so that it can accommodate a deep lockable door -- doable but I worry about

a.) that the extension will look tacked on

b.) that the ergonomics won't work as the deep door will push the drawer fronts some inches further back under your bench compromising the accessibility of their contents.

c.) when open the door will obstruct a lot of your underbench space (and if it doesn't fully open obstruct your work space), and

d.) a lock engaging into the 17mm carcass side might be difficult to access.

4. you can build a box that the chest can slide into with a shallow lift off door -- a la the cases used to protect campaign furniture. This option retains the design and construction integrity of the existing chest while allowing the drawers to be secured as required. The box can be very plain and only needs to be a a few mm deeper than the thickness of your door plus the knobs on the chest. Something like the drop panel on this chest

A deep door that could be used as a saw till I feel suffers from all the ergonomic negatives as for option 2, UNLESS the door is always lifted off when you open it. AND a lift off door is really just a panel.

However, if a primary objective is to produce a lockable chest, then perhaps you can retro fit a pocket or two within the existing drawers which will accommodate a drop bar -- like what is used on a dutch tool chest to retain and lock the removable panel -- and install a standard drawer lock on the top drawer.regards from Alberta, Canada

ian

-

9th April 2016, 08:20 AM #8

If security is the main issue rather than evolving the design and function, perhaps simply adding a locking flap is a solution.

-

9th April 2016, 08:30 AM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Ian,

All very good suggestions. Thanks for taking the time. Greatly appreciated.

I don't want to do #1 because, at the end of the day, I'm super pleased with what I've built and even if the front can't be added then, as you say, it's still a great chest of drawers.

#2 just sounds hard, to put it mildly!

I definitely appreciate all the points in #3. If I do anything it will likely be to add a door to the front, which is seeming less and less doable, but it's still on my radar.

3A is a major consideration and is one of the most significant things I DON'T want to end up with. 3B is something I've given some considerable thought. As it stands, I've already got the chest installed a couple of inches back from the front of my bench. The drawers are installed using medium duty runners (30kg. They look godawful when open, but the situation required it ) which are full extension. Any brainstorming I've done about this front, recessed door has taken this depth into consideration, so it won't require me to push it back any further and the drawers will still be just as accessible. 3C shouldn't be an issue because, as it stands, I would never be able to leave the door open anyway while working because of exactly what you said about how it will obstruct my workspace/stance space. 3D will, I think, be ok. This isn't something I would lock every day/night. I would probably lock it fairly infrequently when I knew I wasn't going to be using it the next day or something like that.

) which are full extension. Any brainstorming I've done about this front, recessed door has taken this depth into consideration, so it won't require me to push it back any further and the drawers will still be just as accessible. 3C shouldn't be an issue because, as it stands, I would never be able to leave the door open anyway while working because of exactly what you said about how it will obstruct my workspace/stance space. 3D will, I think, be ok. This isn't something I would lock every day/night. I would probably lock it fairly infrequently when I knew I wasn't going to be using it the next day or something like that.

At this point I think I have more or less decided to just build the door to the specs the bench will allow and do a dry fit without cutting any hinge mortises or installing any hardware and just see how it goes. I've not built anything like that before so it will be worth my time to experience creating a frame and panel door that has to be very precise because it will be on the "show" side. I also think that matching one dovetailed carcase to mate face to face with another to within tolerance should be challenging/rewarding.

It'll be a few weeks before I find that round tuit (work and holiday), but I'll post when I get it made. Shouldn't take more than a day or two.

Again, really appreciate the ideas.

Cheers,

Luke

-

9th April 2016, 08:35 AM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

I also thought about this and, if I forego the recessed door idea it will likely happen in some shape or form.

Security is important, but kind of an added bonus which I would just like to work in using a more aesthetically pleasing technique while simultaneously improving function and maximizing use of space. Originally, I was excited about installing a traditional lock mechanism with a keyhole mortise and escutcheon, but because of how I built the carcase that bird has now flown.

-

9th April 2016, 03:42 PM #11

-

9th April 2016, 03:53 PM #12

Luke, thank you for that.

don't discount the value of having those drawers instantly accessible. Originally Posted by Luke Maddux

Originally Posted by Luke Maddux

My current work space is equipped with some of these.

Home Depot's Black Friday deal was just too good to pass up.

Home Depot's Black Friday deal was just too good to pass up.

I have my planes and chisels in one cabinet and have found that I have totally changed how I work.

I now reach into a drawer, select the tool I need, use it and then if unlikely to use it again that day I put it back in its drawer.

I can't see myself doing something similar if there was a door -- that needed to be opened and closed -- between me and the drawers.regards from Alberta, Canada

ian

Similar Threads

-

Round Door cabinet

By Sculptured Box in forum BANDSAWN BOXESReplies: 5Last Post: 30th January 2008, 02:51 PM -

cabinet door construction

By Strungout in forum WOODWORK - GENERALReplies: 5Last Post: 7th October 2007, 10:43 PM -

Glass Door Key Cabinet WIP

By Lumber Bunker in forum WOODWORK PICSReplies: 12Last Post: 22nd November 2006, 10:06 PM -

Newbie-How do I fit glass into cabinet door?

By trainingwheels in forum WOODWORK - GENERALReplies: 12Last Post: 9th February 2006, 01:36 AM -

Cabinet Door Set With or without Backcutter

By boxers in forum ROUTING FORUMReplies: 4Last Post: 26th August 2005, 05:26 PM

Likes:

Likes:

Reply With Quote

Reply With Quote