Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 75 of 124

Thread: Show off your workbench

-

18th April 2007, 08:16 PM #61

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,788

3m long - SHEER LUGXURY MATE - there shoulde be rules against that sort of thing

!!.

!!.

I was thinking of something more like a door or a frame which goes all or part way to the floor that you might side clamp rather than top clamp.

On another matter I have had some requests to show you what's in my bench vertical drawers, so here as some new pics.

There are 3 drawers so there are 6 sides and a space under the vice.

First the tidy end.

Drawer 1) Chisel/Plane drawer on both sides. Yes I have a set of those blue plackky handle jobbies but they're just filling the spaces of some lovely 70 year old FILs chisels that need restoring.

Drawer 2) Marking out. On the very right you can also see the dark Sheoak marking gauge I made 40 years ago in High school woodwork class.

The second side is still not fully populated. Note the restored 45 year old Brace and Spiral Screw driver that still work a treat.

There is also hanging space on the inside back of the drawers that could be used, but it's quite hard to reach.

-

18th April 2007 08:16 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

18th April 2007, 08:20 PM #62

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,788

Now the less well organized bits.

Drawer 3: I don't have a lathe but I picked these cheapies up at a garage sale still in their plastic so I stuck them in a rack. I have used them in anger at work a couple of times.

Cuppboard under the vice. Holds my mini-shooter, bench hook, feather boards, various other clamps and jigs etc. This is the cupboard that I always need to get something out of when I have something in the vice blocking the access to it.

Like everything in a shed it's a WIP.

Cheers

-

18th April 2007, 09:05 PM #63

Why two face vises?

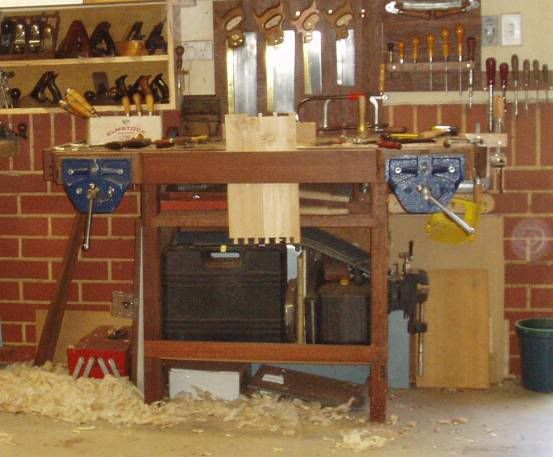

Here is a an early picture of my bench using a board spanned between two vises to make a dovetail vise.

Another idea: clamping two long boards together to edge joint.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

18th April 2007, 09:50 PM #64

zelk

zelk

- Join Date

- May 2006

- Location

- sydney

- Posts

- 694

Derek, your vices look like beasts. I was wondering, should one of the vices be in the way, can they be easily removed? I have a 4 inch Record mechanics vice which I would like to attach to the bench when required, I am considering using the woodworkers vice to somehow hold and support the mechanics vice. I will certainly be using the workbench to store my clamps, giving the bench some weight and freeing up some workshop wall space

Zelk

-

18th April 2007, 09:53 PM #65

I was trying to keep out of this one, cos I didn't know whether to show-off the nicest bench, which was done for a friend, or my own somewhat more prosaic model.

OK, why not both? Here's mine (pics 1&2) - made about 22 yrs ago (I can age it because one of my daughters is the same vintage). Made from Sugar maple bought from a small Mennonite mill in Ontario (the top) and the undercarriage from sugar maple I salvaged from a windfall tree. The back stretcher has a small 7/16 hole and metal stain from a spial (the 'tap' they drive in to collect the sap in Spring).

It's basically a good bench and serves me well, but dammit, I made it just 100mm too short, judging by how many times I want to clamp a piece about 2M in the dogs, and it just won't quite fit! (The size was largely dictated by the material I had, which in turn was dictated by my rather small budgetry allowance at the time!). If holding long bits in the front vice I use a board held in the tail vice, drilled to take a peg every couple of inches (which went AWOL in the last move, so gotta make a new one. )

)

Also been meaning to make a clamp for dovetailing wide boards something like Dereks, 'cept my idea is just to tap a hole in the apron & use the vice plus a wooden screw. I'll definitely do it next time I have a wide board to dovetail (which is what I said before I did the last one ).

).

The vices are made with scraps of black walnut, with leather facings in the jaws. The tail-vice screw is a chunk of Rosewood (Sth American) that someone once gave me - gorgeous to turn & thread. (Hate to think what it would cost today!) This shot also shows the small cupboard and set of drawers that fit underneath - they are screwed to the stretcher so that the whole thing is easily demountable, though I hope I don't have to move it ever again - by some perversion of the laws of conservation of matter, the #%@!! thing gets heavier every year!

And pic 3, my solution to keeping wooden dogs in place - a bullet catch in the side. And you probably know why wood is my preferred dog material.

Pics 4&5 are of the 'fanciest' bench I've done. The top is mainly Sydney bluegum (a trade for a job done for a former colleague) and the base is Redgum, again harvested from an old fallen log. The tail vice screw is Bull oak (Casaurina Leumanii) and the handle is a scrap of nice, dense Blackwood. This one doesn't move under any sort of reasonable use!

Cheers,IW

-

18th April 2007, 10:03 PM #66

Yeah, Zelk, I did that for quite a while when I had extremely limited shop space. Just bolt the metal vice to a solid chunk you can grip firmly in the woodworking vice, without raising the second vice too high for comfort.

Only downside is you often do messy things with metal vices, & metal filings seem to be able to jump several feet to find sharp edges! Even when your tools have never been near a magnet, they are frequently magnetised enough to pick up small ferrous particles. It's one of the reasons I shun using magnetic tool-holders - hate magnetised tools! (Unless it's a screwdriver bit that's meant to hold screws while you start 'em.)

Cheers,IW

-

18th April 2007, 10:19 PM #67

zelk

zelk

- Join Date

- May 2006

- Location

- sydney

- Posts

- 694

[quote=IanW;498238]

Only downside is you often do messy things with metal vices, & metal filings seem to be able to jump several feet to find sharp edges!

Good point IanW, might make a smaller fixed workbench for the mechanics vice and bench grinder.

Zelk

-

18th April 2007, 10:28 PM #68

Yep - now I have the luxury of a bit more space, I made a metal-working bench, AND a separate grinder station.

(Smug B.! - but I am revelling in the comparative luxury after so many years of being cramped beyond endurance)

IW

- but I am revelling in the comparative luxury after so many years of being cramped beyond endurance)

IW

-

18th April 2007, 10:39 PM #69

TassieK,

Almost without doubt the cup is due to differential movement in the laminations. In my view the pieces would have been better oriented at right angles, or "quarter sawn" in effect. Had that been the case, the movement would have been almost entirely in a horizontal direction.

As it is, even though the differences between each board may be slight, they are moving vertically, and at different rates.

I'd welcome discussion on this, but have been a stickler for this in joinery specs for nearly three decades without major failure!

cheers,

P

-

18th April 2007, 11:52 PM #70

Ian

I would kill for either of your benches! You do really great work. And you have good taste in timber. AND you have a near endless supply of it! Damn I'm envious.

Keep in mind that the above picture of my bench is some years old. One day I will find the time (and space?) to build one like Ian's, but mine does go through a gradual upgrade every now-and-then.

Here is a recent picture ...

How many objects can you name?

Actually, while only about 5 feet, I do not use an end vise, and the planing stop (see earlier picture) enables me plane quite large panels.

And here is one more add-on for a basic bench .. I lacked the correct place for a metal vise, which had to be moved to make way for a grinder, so I screwed it to a base that could be clamped in one face vise (and over a leg) ..

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

19th April 2007, 02:49 AM #71

Hi Bitingmidge,

I'm interested in what you've said about the movement in TassieKiwi's bench and just wanted to check my understanding. If you look at the end grain of the laminated pieces of timber in bench you can see that it runs roughly horizontally. Are you suggesting that the grain would be better running vertically from the point of view of wood movement?Regards,

Ian.

A larger version of my avatar picture can be found here. It is a scan of the front cover of the May 1960 issue of Woodworker magazine.

-

19th April 2007, 09:08 AM #72

-

19th April 2007, 09:17 AM #73

Well Derek - we need to discuss this!

Please, me old China, no need for violence - if you was THAT desperate, I'm sure we could reach some sort of raprochement! Much as I like my bench, It can always be improved on, so if my better half were to catch me building a new one, I could offer the excuse that a nasty man in Perth has threatened me......hmmm?

Like everyone else here, I know when you stop churning out the endless line of pretty impressive things from your present set-up, & turn your mind to it, you'll probably produce something to make the rest of us envious! See, ya don't need a fancy bench to do great work. On the other hand, ya DO need REALLY good bench tools. Now, about some of them fancy planes and saws in YOUR kit - I think a little bit of constructive homicide needs arranging, eh, fellas???

No argument.

To be truthful I don't think I have any! My tastes are VERY catholic - if it's free, it tastes good!

I was going to protest this one, too, but then I thought maybe this is a point that deserves a serious answer. You're right, if you keep an eye out, and you're in th eright place at the right time, there is a lot of both good & free wood to be had, alright. I think we are a bit better off for choice over here, & yeah, I do seem to amass the stuff faster than I can use it at the moment. Just can't bear to pass up useable wood of almost any kind. T'other day I was out for my daily jog & saw a whole heap of dumped packing crates waiting to go to landfill. I went & had a look, and there was all sorts of useful stuff, like several large sheets of pretty good quality 3/8 ply (I'm slowly lining the shed with cast-offs!) and enough pine/spruce softwood of various shapes, lengths & sizes to make the last cupboard I need twice over (with less than the usual complement of nails, even). So I spent the rest of my lunch-hour dragging out as much as I could get at. The tractor operator came back from his lunch in the middle of the operation, to my initial embarrasment at being sprung, but he was all for it, and even offered to drag some of the less accessible bits out for me.

And there has been a goodly number of street trees/other kinds of windfalls come my way over the years - I'm lucky that I'm the only wood nutter with chainsaws and attitude known to a bunch of people, so I get called when something looks promising. Of course, I've had to forgo more than my fair share of goodies, too, either from lack of time or in too difficult/dangerous a situation.

There is tremendous satisfaction in making something lasting from raw trees, like the kitchen chair set I'm (very slowly!) completing at the moment (spindles of River-Oak from a couple of windfalls in the creek adjoining our property, and seats & backs of Jacaranda that blew over in a big storm a few yrs ago). I often think I'm nuts for spending all that time and effort (milling rough stuff like this gives about a 30% yield at best, so a lot of sawdust and firewood gets created) but it's the only way to get wood with the properties I'm after, many times. The clincher, of course, is the satisfaction you get when something you make from scratch works really well, and the material you chose suits the purpose perfectly, as you well know, I'm sure, each time you weild that thumping big new jointer of yours!

Avagooday,IW

-

19th April 2007, 09:42 AM #74

Mirboo, that's EXACTLY what I'm suggesting!

Unfortunately I don't have time at the moment to find some suitable diagrams, but if you consider that the bulk of movement happens perpendicular to the growth rings, and that varies depending on the curve and the spacing (soft/hard wood), it's almost impossible to line up identical boards which will have the same movement characteristics.

On the other hand, if the grain is aligned vertically, and adjoining boards expand/contract at different rates, it has no impact on the horizontal plane.

I hope that's clear enough.. maybe I need to go hunting! Usually articles on milling timber have fairly clear information on this, but I am surprised that very few people seem to consider it.

Cheers,

P

-

19th April 2007, 10:44 AM #75

Peter - this ain't necessarily so. In fact, I think with most woods, radial movement is LESS than tangential. "Stable" woods are those with almost equal radial/tangential movement, according to Hoadley. You're probably far more adept at maths than I, plus your background, so I'm being pretty cheeky to debate this with you!

The simplest explanation for the differential movement is that the further out you go in the tree, the 'younger' the wood, therefore less gunk ('extractives') has been deposited in the lignin walls, so the more room there is for water, & when it leaves during the 'drying' process, more shrinkage. This is why a plainsawn board always cups concave on losing moisture (viewed from the outer side) and convex on taking in more moisture (e.g. when a board kiln-dried to 5% is left to equilibrate in a Brissy shed in a normal January).

The relative stability of quartersawn boards is just that - relative. You still get shrinkage and contraction, but if the growth rings are perfectly parallel to the narrow dimension, you a) minimise movement and b) it's EVEN. BUT, there will still be more movement in the younger wood than the older ('inside') wood. The only time I pay attention to orienting wood for glueing is if it's quartersawn, and then I make sure to match heart to heart, and outer rings to outer rings. Otherwise, the difference in seasonal shrinkage/expansion will put undue stress on the glue joints at best, or create palpable ridges, at the joins, at worst.

There are just so many other factors that affect the way wood moves in a glued-up lamination - the species, thickness, proportions of 'sap' to 'heart' wood (not very easy to determine with many of our hardwoods!), etc., how well-equilibrated it was to begin with.........

Glad I'm not an architect!

Cheers,IW

Similar Threads

-

Melbourne WWW Show

By TritonJapan in forum TRITON / GMCReplies: 9Last Post: 25th October 2006, 08:31 PM -

@*&%$*! postjumping **&$@&%! - HELP!

By TassieKiwi in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 3Last Post: 27th April 2006, 09:33 AM -

Sydney Wood Show Vs Canberra Show

By I_wanna_Shed in forum WOODWORK - GENERALReplies: 8Last Post: 10th April 2006, 06:16 PM -

What did you buy at the wood show?

By soundman in forum WOODWORK - GENERALReplies: 16Last Post: 25th May 2005, 11:00 PM -

Melboure Wood Show Prices

By Sir Stinkalot in forum HAND TOOLS - POWEREDReplies: 4Last Post: 9th October 2003, 11:06 PM

Reply With Quote

Reply With Quote