Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 16

Thread: High Angle Frog for LN #7

-

19th June 2020, 06:50 PM #1

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

High Angle Frog for LN #7

High Angle Frog for LN #7

Hi,

Just got a LN #7 second hand however it has a low low frog angle (45 deg). Have you got a LN High angle frog 55 degree that fits this plane to sell. Shoot me a few photos and an offer price. Thanks

Cheers,

Bernard

-

19th June 2020 06:50 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

20th June 2020, 05:37 PM #2

Bernard

you should find that once you learn to use the chip breaker correctly you won't need a 55 degree frog.

extracted from the Highland woodworker

Seven Steps to Peak Handplane Performance

Adjust the Chipbreaker

For smoothing most hardwoods, 1/32 inch is good, though you may want to set it at 1/64 inch for difficult woods prone to tearout. For softwoods, 1/16 inch may be more appropriate. The distance will vary for individual planes set up to achieve different results.

NB

1/32 inch = 0.8 mm

1/64 inch = 0.4 mm

1/16 inch = 1.6 mmregards from Alberta, Canada

ian

-

21st June 2020, 12:29 PM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,278

In addition to Ian's advice, I would also recommend

- set the bevel to a higher angle, I use a 40 deg bevel, instead of the 25 deg default.

- If you have tried everything and still are not happy, you can simulate the 55 deg frog with a 10 deg back bevel on your blade (normally we grind the back of our plane iron flat, in back bevelling, we take 20 degrees off. This would get you an equivalent of the 65 deg frog. Of course the higher the frog angle, the bigger the effort needed to push your plane. Its a trade off. 10 deg back bevel might well weaken the blade.

-

21st June 2020, 08:43 PM #4

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

Hi Justonething,

Thank you for your comment.

1. For a BD plane, my secondary bevels are at 35 deg. Would changing the plane blade bevel from 25 to 40 deg mean that the bevel is a tad stronger, however will last a bit shorter when compared to the 25 degree. Because of the wear bevel being formed quicker.

I will use a 40 degree bevel for my chisels soon because my titan mortice chisels chip in ironbark.

2. Back beveling sounds a bit scary to me. I would have to buy a new blade when I'm working with softer timbers. I mainly work with Ironbark and spotty by hand. I feel like switching frogs would be easier than switching blades. And you're right, adding a back bevel would maybe weaken the blade. I get that a higher bedding angle would be a tad harder to push. I feel that sometimes with my HNT planes.

Thank you for your comment

-

21st June 2020, 08:52 PM #5

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

Hey Ian,

Thanks for your tips. I am just trying to turn my LNs into HNT gordons with the bedding angle. I find that for my #4.5 it does works a lot better with the high angle frog. I will tinker with the chip breaker when I'm with my planes next.

Thank you,

Bernard

-

21st June 2020, 11:22 PM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,278

- The max bevel can not exceed 45° so 40 is about as high as you can set it. A more acute angle will allow more flexing at the tip. You are right that the edge with a higher bevel demands more frequent sharpening and requires slightly more effort in pushing the plane. It is even more important to have an effective sharpening technique.

- Back Bevels and Plane Geometry – The Sharpening Blog;

- The higher the angle, the closer to scraping you are. Also, you can try back beveling on an old stanley iron, they should be quite cheap to have compared to a 55° frog.

-

22nd June 2020, 02:13 AM #7

you already have a 55 degree frog

you already have a 55 degree frog

Hey Bernard

Have you overlooked that the L-N #4-1/2, #5-1/2, #6 and #7 all use the same width blade and therefore share the same frog? (And also the same locking and adjusting screws.)

swapping the 45 degree frog in your #7 with the 55 degree one in your #4-1/2 will get you a much harder to push #7 without any expense at all.

On back bevels and the like ...

A BD plane cuts wood fibers with the BACK of the blade.

A 25 degree main bevel -- achievable by hollow grinding the blade at 25 degrees -- will give you an adequate clearance angle.

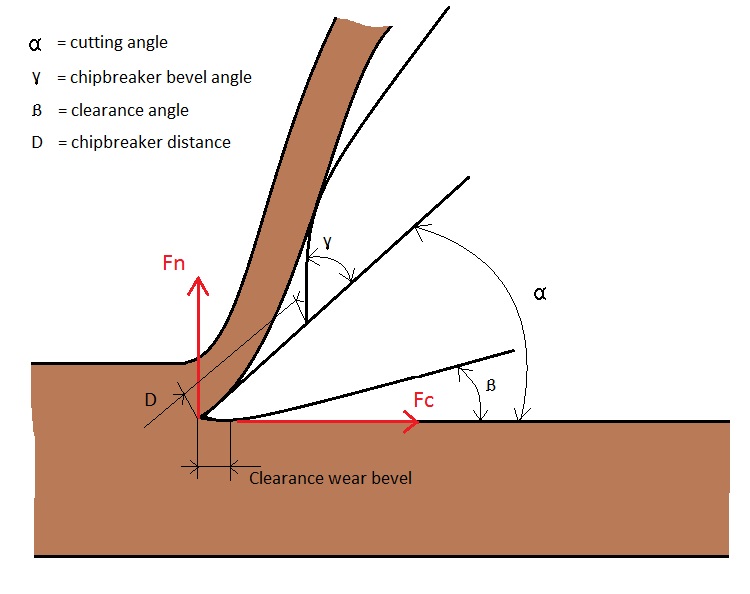

(Your clearance angle needs to be about 11 degrees, however any discussion about the minimum required clearance angle is meaningless for a BD plane, a 25 degrees clearance angle is much more than enough -- different story for a BU plane)

so my advice is to keep the plane blade's primary bevel at 25 degrees to maximise the blade edge's stiffness.

By adjusting the chip breaker's set back to 0.4 mm (1/64 inch), your #7 plane will be harder to push because the chip breaker will be forcing the chip to curl at an angle equivalent to or greater than that achievable with a HN Gordon plane.

For me, back beveling a plane blade was an ill informed person's response to the tear-out resulting from setting the chip breaker too far back from the blade edge.

(the adage that a "poor workman blames their tools" was more a reflection that an poor workman didn't know how to tune their tools to perform.)regards from Alberta, Canada

ian

-

22nd June 2020, 10:43 AM #8

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

Hi Ian,

Yes I am aware that those planes share the same frogs and blades. I will switch the frog and give it a go with what you described.

Noted about the other advice.

Thank you for your comment.

Regards,

Bernard

-

22nd June 2020, 10:45 AM #9

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

Hi Justonething,

Thanks for sharing the link.

I understand what you're talking about with the bevel angle not exceeding 45 deg. For sharpening I use shapton glass stones 1000,3000,8000,16000 with MKII jig.

Regards,

Bernard

-

22nd June 2020, 11:47 PM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Nov 2012

- Location

- SE Melb

- Age

- 64

- Posts

- 1,278

A really sharp blade will let you getaway in a whole lot of situations, and it's particularly useful when the bevel angle is large. Even if it is razer sharp, it gets blunt pretty quickly. If it isn't that sharp, it might not also be useful at all. You seem to have a pretty good setup there.

I have some excellent success with a 35 ~ 40° bevel angle, more so with 40°, especially now that I'm becoming more competent with sharpening. When I say 40°, I refer to the final bevel angle. I have noticed it matters little what the primary bevel angle is. I have many blades with different primary bevels, some at 25, some at 30 and some with just a single bevel angle at 40°, and they are all similarly effective.

Planing involves both splitting as well as shearing (cutting) fibres. When planing, fibres are split along the back of the iron and the same time, the severing of the fibres is being carried out by the same edge along the bevel. A small angle bevel favours splitting and a wide bevel favours severing. When there is more much splitting and not enough severing, tear out is resulted.

Finally, there is no magic that I know of about having a 25° bevel. See Paul Seller's article.

-

23rd June 2020, 12:12 AM #11

Bernard, I would not recommend the route you want to travel. There are reasons why a HNT Gordon works well with a 60 degree bed (and cutting angle), and this will not translate to a LN #7 ... or any other LN bench plane, including the #4 1/2.

The HNT Gordon works because it has a slick wooden sole on which to slide. It is a low centre of effort plane, and requires less force to be driven forward. It is also designed to only take very fine shavings. These also require less effort, but are inherently less efficient. I love the HNT Gordon planes, and have a few, but they have their own place, and this must not be viewed as the same as a LN.

LN make a 55 degree frog, and no higher. For our Aussie interlocked timbers, this cutting angle is often not enough. So going to this frog is often wasted expense. Believe me, I know. I have tried them all, owned them all, and eventually settled on 45 degree frogs. I learned to use the chipbreaker to control tearout, and this works better than any other form of tearout control, and can run rings around a HNT Gordon on the more interlocked timbers.

Don't believe me? This was over the weekend: Interlocked Jarrah ... and into the grain!

That's a LN #4 1/2 Anniversary (bronze) with a 45 degree frog (they came with 50 degree frogs. I once owned a 55 degree frog).

To make this point (about bed angle) even more, here is my Veritas Custom #4, planing Jarrah, and this one has a 42 degree bed. My Custom #7 jointer has a 40 degree bed. Now that is the best of both worlds - the lower the cutting angle, the better the surface finish, and yet it can plane into the grain, across the grain, and end grain equally well!

Building a hidden drawer.

My advice, along with Ian, is to learn to master the chipbreaker. It will open many doors to you.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

23rd June 2020, 12:56 AM #12

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

Hi Justonething,

Thank you. That is a great diagram. Thank you for that. I will try out what you told me on my old Stanleys. Thanks for linking the Sellers' article. Reading it now

Appreciate it!!

Regards,

Bernard

-

23rd June 2020, 01:09 AM #13

I shall be blunt - a 40 degree bevel angle is a recipe for premature dulling. On a 45 degree frog, you have 5 degrees of clearance. As soon as a wear bevel develops, and it will, the plane will stop cutting.I have some excellent success with a 35 ~ 40° bevel angle, more so with 40°, especially now that I'm becoming more competent with sharpening. When I say 40°, I refer to the final bevel angle. I have noticed it matters little what the primary bevel angle is. I have many blades with different primary bevels, some at 25, some at 30 and some with just a single bevel angle at 40°, and they are all similarly effective.

I shall be blunt - a 40 degree bevel angle is a recipe for premature dulling. On a 45 degree frog, you have 5 degrees of clearance. As soon as a wear bevel develops, and it will, the plane will stop cutting.I have some excellent success with a 35 ~ 40° bevel angle, more so with 40°, especially now that I'm becoming more competent with sharpening. When I say 40°, I refer to the final bevel angle. I have noticed it matters little what the primary bevel angle is. I have many blades with different primary bevels, some at 25, some at 30 and some with just a single bevel angle at 40°, and they are all similarly effective.

The highest recommended bevel angle for a Bailey-design plane is 32-33 degrees, which recommended by David Charlesworth, whose advice I respect. I do not respect Paul Sellers in this area. He has no experience with hard, interlocked timbers. His methods are geared to beginners planing easy, softer timbers.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

23rd June 2020, 01:45 AM #14

Senior Member

Senior Member

- Join Date

- May 2020

- Location

- Melbourne

- Posts

- 118

Hi Derek,

I am a fan of your website! Constantly browsing thru it!

Thank you for your comment and accompanying photos. It is very interesting that you say that, because I do find that my HNT Gordon planes can take ultra thin shavings however they're not the best at taking off more material.

I just have a few more q's

If a LN with a 45 deg frog and a 1/64" chipbreaker distance eliminates tear out in Aussie timbers.

- Function wise is there a place for a HNT Gordon plane for tackling Aussie hardwoods? Smoothing applications?

- If both planes are set up correctly, would a LN 4 1/2 out 'smooth' the HNT Gordon smoother (60 deg bedding angle) for Aussie hardwoods? Or would a Veritas BU smoother knock the two aforementioned planes out the park when it comes to smoothing Aussie hardwoods.

- When would you use HNT Gordons over LN planes?

- When would you feel a 55 degree LN frog is 'necessary' (if ever) and why? Foreign/exotic/ringed timbers?

What would be your ideal scrub plane for Aussie hard woods?

-Would a Stanley #5 (standard frog) with a heavily cambered blade be better than a HNT jack with the same radius blade (55 deg bedding angle)? With all factors considered [weight of plane/center of effort/ blade metalurgy difference (vintage Stanley blade vs HNT HSS blade)]... and other factors that may be escaping me right now... or a new Veritas/LN scrub plane.

After an initial read of your comment, it seems like I should put the HNT Gordons in storage once I get the LNs set up correctly. I would love to hear your thoughts

Thank you in advance

Regards,

Bernard

-

23rd June 2020, 04:41 AM #15

Hi Bernard

A great article on setting the chipbreaker: Setting a Cap Iron

The actual distance varies according to the thickness of the shaving. I generally set it 0.4 - 0.5mm from the edge.

A closely set chipbreaker will perform better than a high cutting angle, whether high bed (HNT Gordon) or high angle blade (BU plane). A high cutting angle on a single iron plane can work very well. The advantage is that it is relatively easy to set up and use. But the limitation of a high cutting angle is that one can only take fine shavings - thick shavings will encounter much resistance, and the wider the blade the greater the resistance. Further, a lower cutting angle will produce a cleaner, shinier surface, so the aim is always to use the lowest cutting angle one can get away with.

Why does LN (and Veritas) produce a 55 degree frog? Because that is as high as is needed for the more interlocked North American timbers. Their “tough” stuff is generally tame by our standards.

I cannot imagine using a jack plane with a 55 degree cutting angle (as in the HNT Gordon). It does not make any sense. The jack is a coarse plane and designed for rapid waste removal. A high cutting angle limits the thickness if the shaving and becomes hard work. I use a #5 (actually, a Stanley #605) with a 10-12” radius camber). I have nit bothered with a scrub plane in several years.

Do not neglect the HNT Gordons. I really like mine and use three quite a bit: smoother, palm plane, and trying plane (for jointing short boards).

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Which frog angle?

By groeneaj in forum HAND TOOLS - UNPOWEREDReplies: 7Last Post: 30th April 2011, 10:50 PM -

Having trouble understanding low-angle vs high angle planes

By wsal in forum HAND TOOLS - UNPOWEREDReplies: 4Last Post: 2nd December 2008, 12:04 AM -

High angle planes???

By Toolin Around in forum HAND TOOLS - UNPOWEREDReplies: 7Last Post: 10th June 2007, 09:02 PM -

Low angle vs. High angle Planing

By silentC in forum HAND TOOLS - UNPOWEREDReplies: 68Last Post: 1st November 2006, 03:56 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote