Needs Pictures: 0

Needs Pictures: 0

Results 1 to 12 of 12

Thread: Bandsaw Feeder

-

14th October 2016, 08:45 AM #1

Intermediate Member

Intermediate Member

- Join Date

- Mar 2009

- Location

- Windsor

- Posts

- 30

Bandsaw Feeder

Bandsaw Feeder

Hi all,

After pushing through roughly 15kms of timber through my bandsaw to make laminations for my furniture in the past ten years I have stuffed both shoulders and require a second operation on my right shoulder. For me to continue to be designing and making furniture full time in the future I am going to have to purchase a bandsaw/resaw feeder. I am looking at the "CO-MATIC AF-19 BANDSAW FEED UNIT" sold by Leda and then fitting it with a pneumatic cylinder in place of the spring so that one, I will have a constant pressure applied to the timber against the roller fence and two, I dont have to be pulling back on the spring for every time I have to put the timber through, which is a lot. I will be mounting this to a metal stand on lockable castors and clamping this to my bandsaw so that it can be removed so the bandsaw is not tied up for just resawing.

My question is has anyone purchased this or a similar unit and if so could you please let me know how you found it and was it worth the purchase.

This is the link to the Leda product http://www.ledamachinery.com.au/index.php/feeders/co-matic-af-19-bandsaw-feed-unit-detail

Thanks in advance,

Darren

Darren Oates Fine Furniture

-

14th October 2016 08:45 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th October 2016, 10:25 AM #2

Hi Darren

I haven't used a power feeder with a band saw.

However, in terms of your proposed arrangement -- mounting the 80kg feeder on a movable table so that the feeder is no more than 210 mm from the blade. I'd be concerned about how much your productivity would suffer if you're repositioning and realigning the feeder on a regular basis.

Perhaps you should consider permanently mounting the feeder and using a second band saw for stuff that doesn't require the resaw capacity of the larger saw. I note that Leda also have a resaw band saw with integral feeder.

There's also an issue around whether your existing band saw is powerful enough and sufficiently rigid to support the use of a power feeder.regards from Alberta, Canada

ian

-

14th October 2016, 06:22 PM #3

Intermediate Member

Intermediate Member

- Join Date

- Mar 2009

- Location

- Windsor

- Posts

- 30

Hi Ian,

I currently have a 24" bandsaw driven by a five HP 3 phase motor and I have chosen the CO-MATIC AF-19 BANDSAW FEED UNIT as you can vary the speed right down to one meter a minute which is slower than what I manually feed the timber through. There is not enough room on my bandsaw to fit this unit and I would not think the top would be strong enough anyway, but the stand I will be making will take a bit of time to set up each time but as most of my timber is made from curved laminated components, I will set this up and then spend an entire day cutting laminations that will keep me going for months, then it is taken off and back to being a standard bandsaw. My only concern which is why I really want to be able to converse with some one who has purchased one is how it feeds the timber and if they experience any slippage or any other problems they may have encountered as this is going to be quite an expensive exercise, but very necessary for me to continue making furniture and paying the bills.

Cheers

-

14th October 2016, 07:54 PM #4

New Member

New Member

- Join Date

- Sep 2016

- Location

- melbourne

- Age

- 42

- Posts

- 1

hi,

please help me with starting cap value for CEDET MOTOR 1/2 hp 220/240 Volts 3.6 AMPS AC 50 c\s 2850 rpm specification shown in pic.

sorry for this reply coz i dont know how to do new post

thanks

-

15th October 2016, 03:21 AM #5

Hi Darren

I have my doubts that the feeder you're looking at can be successfully mounted on a table separate to the band saw.

Reading around the web, the AF19 is pretty much the standard band saw power feeder.

Laguna have a picture of one mounted on a saw which looks a bit smaller than 24".

Given the direction of the forces to be resisted, short of two steel plates bolted to the band saw's table, I can't see an alternative to mounting the unit directly to the band saw table as shown by Laguna.

an alternate mounting

Some Comments

from Bandsaw power feed - WOODWEB's Solid Wood Machining Forum

I Set up a Felder FB600 24" bandsaw with a feeder and it works well. I think Comatic is one of the few companies making Power feeders. I have the AF19 but if I could do it over again I would get the pneumatic version. I use my bandsaw to rip and it is awkward to hold a wide long board and reach forward to move the power feeder over to start feeding the board. The pneumatic version opens and begins feeding by itself.

I use a Lennox Trimaster 3 2, 1" wide blade. The blade makes a lot of difference. I get very straight very smooth cuts.

My feeder has serrated rollers and I have not found any reason to want anything else. I have not noticed and marks in the wood from the rollers but I work with mostly hardwood and plane after reassign or use a sander.

I bought the AF19 with a 3 phase motor and added a VFD from Automation direct for variable speed control.

We split 5, 6" to 8" wide x 10' long 4/4 rough Sapele boards today and it took about 10 minutes with nice smooth results.

You will love the power feeder if you are doing this a lot.

Joe in New Orleans

from Sawmill Creek

Van Huskey03-08-2012, 12:42 PM

Regarding power I have seen Laguna demonstrate 18" +/- resaws in relatively hard wood with their medium feeder (just like what Mike is getting) at a fairly slow rate, completely hands off, not sure if it needed to be that slow or was slowed down to show off the finish of the RK blade and/or give Torben more time to chat up the crowd during cuts.

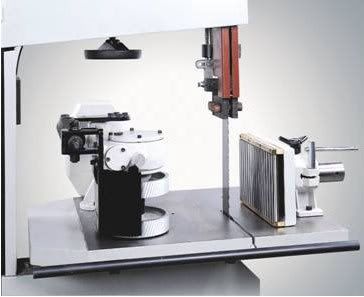

some photos of rebadged AF19 on a 20" Mini Max

regards from Alberta, Canada

regards from Alberta, Canada

ian

-

15th October 2016, 03:02 PM #6

Woodworking mechanic

Woodworking mechanic

- Join Date

- Jan 2014

- Location

- Sydney Upper North Shore

- Posts

- 4,469

-

16th October 2016, 12:47 AM #7

Hi Darren,

I have a Felder F38 feeder setup permanently on the planer, I bought it when K Rudd was throwing money about, from memory about 1K.

If the tables get a bit sticky or I have the wheels lightly loaded it might not drive the board thru, a bit of wax or more down adjustment to load the wheels a little more usually fixes it. This model will feed horizontally and vertically so with a bit of adjustment I can set it up to do edges, in this setup I have often thought I can't see a reason why I couldn't use it on the bandsaw to slice veneers, all I need is a suitable bracket, I setup my BS with outfeed and infeed rails, I made up various mounting points off the colum/frame of the BS to support/locate the rails, it wouldn't take much to add a bracket to support the feeder free from the table.

Here's a few pics of the BS in veneer mode, (a spring loaded roller) you can also see the support framework for the rails

lump of raintree.jpgside view roller.jpgfinished cut.jpg

The F38 can be supplied in either 1ph or 3ph, with the 1ph version there is 4 gear speeds and 2 motor speeds, there would be (at a guess) 2 total speeds that might be close to a suitable feed rate, a better option would be a 3ph motor and a VSD to give variable speed options.

Pete

-

16th October 2016, 06:36 AM #8

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

What about extending the fence rails outward and then mounting the device onto a removable plate that can sit on the extended bars? That way you have the removability as well as the sturdiness of being attached directly to the saw.

Just a thought...

Cheers,

Luke

-

16th October 2016, 06:46 AM #9

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2014

- Location

- Seattle, Washington, USA

- Posts

- 1,857

Or what about a second table purchased from the manufacturer?

-

16th October 2016, 08:46 AM #10

Intermediate Member

Intermediate Member

- Join Date

- Mar 2009

- Location

- Windsor

- Posts

- 30

Hi Ian, after looking at these photos their maybe enough room on my bandsaw to mount the feeder to it, and I would just require a wheeled trolly to move the feeder and mount it to my machine. I am waiting for a response from Taiwan in regards to fitting a pneumatic cylinder to it. Once I get all this setup which will take a while I will post some photos. Cheers and thanks for the replies.

-

25th October 2016, 03:08 PM #11

Hi Darren

I think this is a bigger feeder to the one you're looking at, but some photos from a local business showing how it's mounted (it's on a Laguna saw)regards from Alberta, Canada

ian

-

1st February 2017, 05:22 PM #12

Intermediate Member

Intermediate Member

- Join Date

- Mar 2009

- Location

- Windsor

- Posts

- 30

Bandsaw Feeder Mounting Jig Comp.jpgBandsaw Feeder Comp.jpg

Hi all,

I finally received my bandsaw feeder, which has been on order since mid November, and have fitted it to my jig on castors for fast attachment and detachment from my bandsaw. I have designed this so that it takes less than a minute to attach this beast. The roller fence is also mounted to a 10mm thick plate which is then clamped to the bandsaw table. Both of these solutions are so that I can easily go from a standard bandsaw to a resaw in a short space of time, as I do not have room to have both machines. I spent three hours resawing yesterday and it did not miss a beat, very happy so far, well except for the cast iron guard which broke off in the first ten minutes of using it, but as it turns out is much better for not having it on there, so will not be replacing it as I am the only person using my machinery. Anyway I hope the images are clear enough and maybe give someone else some ideas if they are in the same boat. Cheers

Similar Threads

-

cc/cv wire feeder

By old mate in forum WELDINGReplies: 1Last Post: 16th February 2013, 11:25 PM -

Bird feeder help

By LHoneyman9913 in forum FINISHINGReplies: 1Last Post: 19th October 2012, 06:54 PM -

Fish Feeder

By Glennet in forum PETS, PETS & more PETS.Replies: 1Last Post: 15th October 2010, 07:29 PM -

Bird-feeder

By alexg in forum WOODWORK PICSReplies: 23Last Post: 8th January 2005, 10:07 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote