Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 14 of 14

Thread: Bandsaw Sharpening

-

17th November 2015, 06:34 PM #1

Bandsaw Sharpening

Bandsaw Sharpening

Can someone tell me the name of the guys who are able to sharpen my King Resaw blades. I think it's got Henry in the company name. Ta

Sheddie.If you never made a mistake, you never made anything!

-

17th November 2015 06:34 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

17th November 2015, 07:29 PM #2

Would this be them

-

17th November 2015, 09:55 PM #3

That's them. Thanks mate.

sheddie in recovery still but gettin' there! If you never made a mistake, you never made anything!

If you never made a mistake, you never made anything!

-

18th November 2015, 12:10 AM #4

Sharpen the blade yourself. Just requires a Dremel and about 10 - 15 minutes. I have done several blades now for my Hammer 4400, which is a 17 1/2" bandsaw.

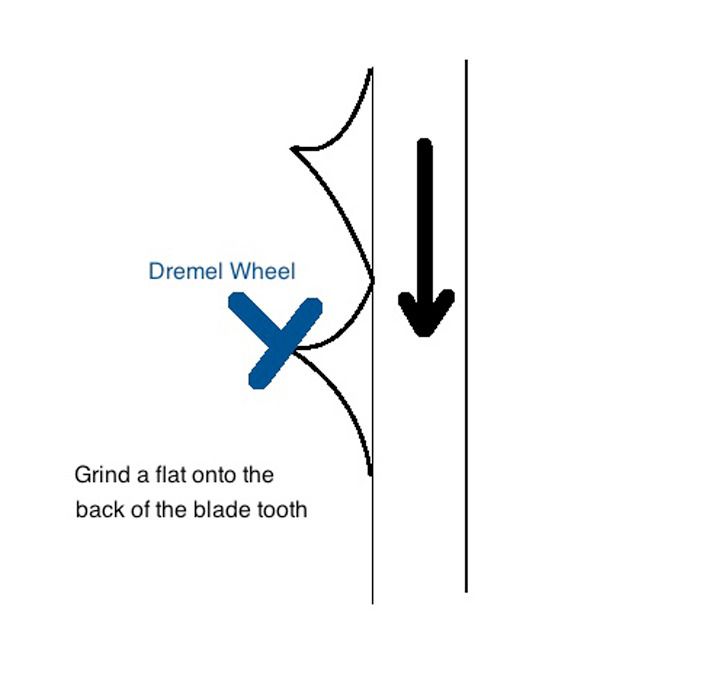

Use a flat disk on the Dremel, and just touch it to the back of the blade tip to create a tiny silver backbevel.

I sharpened a supposedly "new" specialist resawing blade. It was burning wood and wandering - sure signs that the blade was dull. The sharpening was done with the blade on the bandsaw. I just rotated it on the wheels and sharpened each tooth in turn. Once done the blade cut through the hardwood like a hot knife through butter, and was taking even 1mm slices.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

19th November 2015, 03:31 PM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2015

- Location

- Fort Saskatchewan, AB

- Posts

- 79

Derek,

Do you hand hold and just "eyeball" the angle?

Is the angle of the back bevel critical?

My blades are 19 ft. Lots of opportunity for inconsistency.

Thanks

Don

-

19th November 2015, 04:39 PM #6

Hi Don

I just eyeball it. Roughly enough to create a small backbevel that will leave the end of the tooth sharp. How much angle? As little as you need to create the backbevel (using the angle off the back of the tooth as a guide). How wide a backbevel will you aim for? I'd say that mine end up being about 0.5 - 1.0mm.

I can get at least 3 sharpenings per blade. The blade I referred to earlier is a Timberwolf blade. I mainly use bimetal blades, and these sharpen up really well. I know one guy who sharpens his new blades before using them, just because he knows that this method produces a sharper-than-new tooth.

Try it out on an old worn blade first.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

19th November 2015, 04:54 PM #7

I came on a video clip a while back where a bloke uses a bench grinder to just touch up the tips of the teeth. I had a try and found it worked really well. Quick too.

https://www.woodworkforums.com/f27/try-171690

Since I posted that thread my 3tpi blade has had 3 sharpenings and still cuts really well. As you get some practice in it gets easier and you dont have to take off much metal to get sharp.

Regards

John

-

19th November 2015, 04:58 PM #8

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,792

Dereks drawing of teeth may be a bit confusing so maybe try this.

As Derek says the touch up is to the back of the tooth

This will will work a few times but sooner or later the teeth will need to be reset and the gullets reformed. Because metal has been taken off the top of the tooth this will require the removal of more metal than usually required for a sharpen. So you won't get any more total life out of a blade but I guess it saves on sharpening costs.

Loss of set is as important as sharpness on BS blades so after a couple of times of touching up you can get a bit more out of the blade by optimising the set just using a normal saw setting tool. To do this properly you ideally need am accurate set gauge but there are other ways of doing this. You also need to know what your blade set was originally you can match it in future. As per any saw it's very important to not reverse the set of a tooth os this will most likely break the tooth.

-

19th November 2015, 07:01 PM #9

Senior Member

Senior Member

- Join Date

- Nov 2011

- Location

- Mudgeeraba, Gold Coast

- Age

- 84

- Posts

- 178

As has been mentioned above I have tried this chaps method several times with excellent success.

http://woodgears.ca/bandsaw/sharpening.html

Cheers, Fred

-

19th November 2015, 08:56 PM #10

As in the video (not seen before), it is preferred that one lay the blades on a wide table to sharpen. The aim here is to maintain a consistent angle. When I do the teeth with the blade on the machine, I hold the Dremel at a constant angle and pull the blade down to the Dremel disk (which is different from trying to lift the Dremel up and along the teeth of the vertical blade). Why not use a table top? Just that I do not have something this large to use, plus my experience of trying this on my bench is that it was not wide enough to prevent the blade snaking all over the place. It was then difficult to keep the blade in position for a consistent grinding angle.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

20th November 2015, 09:31 PM #11

Senior Member

Senior Member

- Join Date

- Nov 2011

- Location

- Mudgeeraba, Gold Coast

- Age

- 84

- Posts

- 178

Hi Derek,

I make a slot in a solid piece of scrap timber that the back of the blade will sit in with the teeth above the timber. Clamp to the table or bench top and it is not hard to keep a consistent angle as you run across the section in the slot, then just keep sliding the blade around. Hope this makes sense.

Cheers, Fred

-

21st November 2015, 08:35 PM #12

John Heisz made a little jig for his dremel for sharpening while in the saw

https://youtu.be/GRFASuwGodE

-

22nd November 2015, 12:33 AM #13

-

22nd November 2015, 11:50 AM #14

Thanks for the link.

What I do is essentially the same but without the jig. Watching the video reminded me to comment why it is possible to freehand - which requires a steady hand. I do not hold the machine case in my hand. Instead, I have an flexible extension cable. Used this way it it akin to holding a pencil.

So two methods for most: freehand on the table or jigged on the machine.

Regads from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

Bandsaw Blade Sharpening

By newjon in forum SMALL TIMBER MILLINGReplies: 0Last Post: 21st July 2013, 09:09 PM -

Bandsaw Blade Sharpening

By pmcgee in forum BANDSAWSReplies: 24Last Post: 7th October 2012, 06:33 PM -

Bandsaw sharpening

By jmk89 in forum BANDSAWSReplies: 14Last Post: 30th April 2011, 06:12 PM -

Bandsaw blade sharpening

By Paddy in forum BANDSAWSReplies: 1Last Post: 3rd September 2006, 09:06 PM -

Bandsaw blade sharpening

By DavidG in forum BANDSAWSReplies: 9Last Post: 17th October 2005, 01:31 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote