Needs Pictures: 0

Needs Pictures: 0

Results 1 to 12 of 12

Thread: fence needed for bandsaw

-

13th March 2023, 09:21 AM #1

fence needed for bandsaw

fence needed for bandsaw

Our men shed has been gifted a woodmaster 14 inch bandsaw by hare and forbes in reasonable condition, lacking the fence, but rails are with it. probably 10 years old or older and the chances of sourcing the appropriate fence seem remote.As an alternative i see a timber straight edge clamped fore and aft, or perhaps utilizing two magswitches with the straight edge in place of the clamps, both solutions requiring repeated measuring to the blade and then to the mitre slot for a straight cut. Has anyone been in the same situation and come up with a better solution? thanks Ross

-

13th March 2023 09:21 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

13th March 2023, 12:28 PM #2

Went onto Youtube, plenty of ideas there , should have checked first, thanks Ross

-

13th March 2023, 01:59 PM #3

Having a fence on the bandsaw in a men's shed probably isn't a great idea. To many people like to fiddle with adjustments - for say drift etc.

Mobyturns

In An Instant Your Life CanChange Forever

-

13th March 2023, 03:07 PM #4

-

13th March 2023, 07:19 PM #5

Senior Member

Senior Member

- Join Date

- Jul 2008

- Location

- Upper Kedron 4055

- Age

- 82

- Posts

- 157

Fence needed for bandsaw

Fence needed for bandsaw

Drift is a term for an improperly set up bandsaw.

Cheers

Yachtie

-

13th March 2023, 11:44 PM #6

-

14th March 2023, 08:27 AM #7

Senior Member

Senior Member

- Join Date

- Jul 2008

- Location

- Upper Kedron 4055

- Age

- 82

- Posts

- 157

How right you are ! I shouldn't hi jack the thread sorry.

Cheers

John

-

14th March 2023, 09:13 AM #8

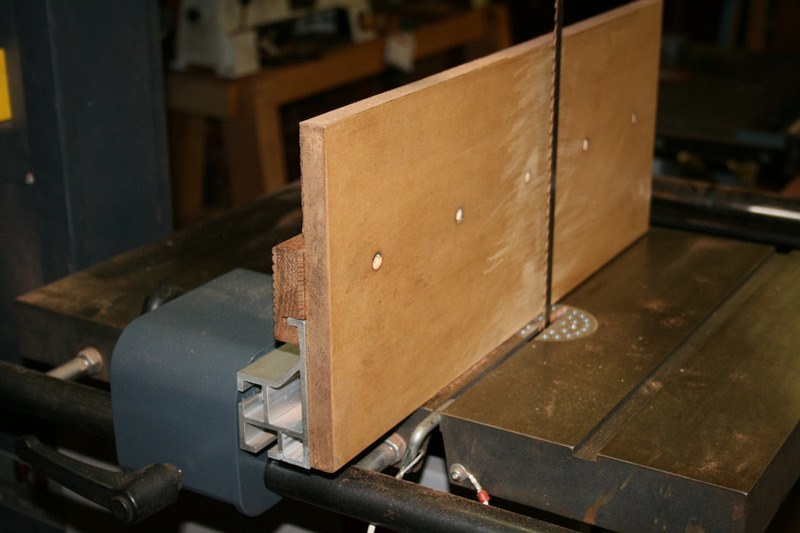

On my mid size band saw I use this stick with a brass top and two magnets glued in the bottom. Pretty handy for cutting multiple things to length like these oak 3/8 pegs and ripping thin stuff to a line. I can adjust for tracking on the go with ripping.

IMG_1615.jpg IMG_1616.jpg

On the larger 30" saw I went to a bit more trouble and made then fitted an adjustable bar and a fence to that off an old Aussie table saw.

Right pic is ripping stacked 50mm Oak.

Once the fence is adjusted with the bar to however the particular blade fitted cuts everything is good from then on . As most who rip stock on a band saw will know. Think I used a bandsaw for 20 years before learning that when we got a new saw with a fence and front bar. You got to re set it for each blade usually. Or at least adjust the tracking of blade on the crowned wheel. Ive never really tried that though. I just set the blade to its normal running spot on the top wheel and test where its cutting on a straight board with a parallel line.

IMG_0599a.jpg IMG_2770a.jpg

-

14th March 2023, 09:54 AM #9

Senior Member

Senior Member

- Join Date

- Apr 2017

- Location

- …ire

- Age

- 39

- Posts

- 300

Some heavy gauge 80x20 aluminium extrusion might be worth seeking out. if you can find it for a reasonable cost,

what will still probably be half the cost of the cheapest fence I guess.

Combined with some angle iron would make for a pretty solid arrangement regarding the fence part...

123435-SAM-6536.jpg

Should it be a single fence rail design?, and say you wish to keep it..

The slotted design of the ali extrusion might lend itself to fence removal should you decide so,

(I didn't think of that and wanted the original rail, hence this malarkey)

Bandsaw fence antics - Copy.JPG

What would have been most sensible was this old design, like on the Centauro's, simply lift it off when not being in use.

Any flat bar would do, with some short offcuts off the end.. i.e

At least two bits sandwiching either side of the rail would make up the bracket, with at least another piece laying on top of the rail.

Some angle iron for the connector and a few bolts.

(I said the "at least" bit, for folks who might not have a welder and wish to bolt all together instead)

pila-tasmowa-centauro-co-600-do-drewna-leszno-537517915.jpg

Can't beat a drop on fence for something which might need doing often.

Keile, Kreise, Kopieren mit der Bandsšge! - YouTube

I doubt if you wanted my answer though, as it's likely too much faff for a machine what's not your own.

Just shooting some ideas, should a few of ye decide to work on it.

Tom

-

14th March 2023, 10:49 AM #10

There are aftermarket bandsaw fences available:

Kreg (at Carbatec)

Sherwood (at Timbecon)

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

14th March 2023, 01:36 PM #11

One thing to consider with a bandsaw fence is the cutting tasks likely to be performed and the best style of fence to support / achieve those tasks, whilst minimizing exposure to potential hazards. A tall fence for slicing veneers, & ripping wide boards; a low fence for small cross section rips.

The fence design on my Woodfast BS500 allows it to be set up with a high or low fence hight, by simply undoing two hex socket screws, rotate the fence 90 degrees then retighten the hex socket screws. That improves safety by minimizing the hazard/s of having excessive unguarded blade height when ripping thin strips. I also use an auxiliary fence clamped (screwed) to the face of the tall fence for intermediate height rips. MDF / melamine board scraps make excellent auxilliary / sacrificial fences as they are of uniform thickness, dimensionally stable, cheap and readily available.

I would also check the table insert on your donated BS to make sure it is effective and serviceable. The plastic inserts that seem to be popular these days don't perform very well imho. I make my own using MDF or ply of suitable thickness with a veneer face if necessary to add thickness to match the ome insert thickness. Many bandsaw mishaps can be traced back to an unserviceable table insert that does not fully support the stock when commencing the cut.Mobyturns

In An Instant Your Life CanChange Forever

-

14th March 2023, 02:47 PM #12

I will pass on my thoughts about bandsaw fence design.

Firstly, as mentioned, there is a choice of a low fence (for most work) and a high fence (for resawing) wide boards. But it is not as simple as this, and I have a modification for both fences to deal with bandsaw drift.

It is worth watching this video about the Little Ripper ...

It is not necessary to purchase (the expensive) Little Ripper to prevent rough and skew cuts. The underlying reason for these needs to be understood. Basically, when a board runs along a fence, the inner tensions inside the wood can spread the kerf apart. One side of the board pushes against the fence, and by doing this it pushes the board out from the fence and into the blade. This occurs on a tablesaw as well, but that is for another time.

What the Little Ripper does is hold a board firmly so that it travels in a straight path, but the board is free to move on either side of the kerf. This movement is into open space, and there is no fence to push against (and to cause deflection).

One way to do this (without the LR) is to use a single point fence, but now you lose the guide of a fence and the cut will not remain straight as you want.

The common resaw fence looks like this ...

Mine looks like this ...

There is enough fence to support a board into the cut, but thereafter the kerf is free to open up where it will not connect the fence.

This creates excellent surfaces.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

Similar Threads

-

SOLD: Bandsaw Rip Fence

By Fuzzie in forum WOODWORK - Tools & MachineryReplies: 16Last Post: 4th December 2020, 06:50 AM -

Minimax bandsaw and Kreg bandsaw fence

By Larks in forum BANDSAWSReplies: 0Last Post: 7th September 2017, 10:26 PM -

Broken Bandsaw fence repair help needed.

By joez in forum METALWORK FORUMReplies: 9Last Post: 23rd May 2013, 01:19 PM -

Screen fence help needed

By glenncol in forum WOODWORK - GENERALReplies: 3Last Post: 3rd June 2006, 02:31 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote