Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 23

Thread: Saw making hammers

-

16th January 2015, 12:09 AM #1

Member

Member

- Join Date

- Jun 2009

- Location

- Holland

- Posts

- 72

Saw making hammers

Saw making hammers

All this talk about saw plates makes me want to work on some saws again. I have a few old ones that needs some attention. Two of them are not very straight and I would like to practice a bit saw smithing. Now, that is rather new for me ( other then random bashing). The chance that I am going to find some real saw smithing tools is pretty slim, so I would like to adapt normal hammers.

How are these things shaped? Is the head simply flat or are they a bit convex? And the edges of the hammer heads? How about the weight? Of course I want to avoid denting my saws.

I have a large chunk of mild steel that is going to be my anvil.

-

16th January 2015 12:09 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

16th January 2015, 12:32 AM #2

Hi Corneel,

I have two dog's head type hammers that you can see in the background of one of my pictures. I got those from Glen Stollmeyer. he told me that those hammers are in the style of hammers used in sword making. they have convex rounded faces with a polished striking face. The sawyers hammer I have also has convex faces, though they are not as convex as are the GS hammers and the surfaces are not polished. The GS hammers are 1.5 and 2.5 lbs. and the sawyers hammer is 5 lbs. The sawyers hammer is one of several that were sold on eBay. If I remember correctly the other two were comparable in weight to the GS hammers I have.

I've found that a critical part of hammering is a decent anvil. It doesn't need to have a mirror finish but rough makes rough.

Overall I've found saw blade hammering to be pretty straightforward, just take it easy and don't dig into the plate with the corner of the hammer face. Nonetheless you'll still need to sand or grind the surface after hammering to remove minor strike marks.

Cheers,

RobInnovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

16th January 2015, 12:37 AM #3

Member

Member

- Join Date

- Jun 2009

- Location

- Holland

- Posts

- 72

-

16th January 2015, 12:47 AM #4

-

16th January 2015, 01:01 AM #5

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

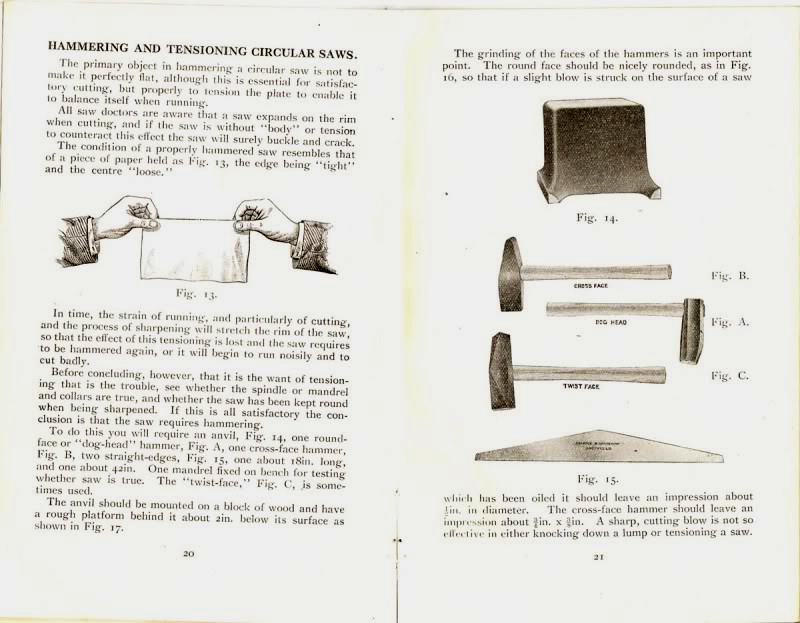

British Saws & Saw Makers from c1660; Simon Barley; published: Oct. 2014; Chapter 1; page 16; Making a saw; Smithing;

The saw plate might at this stage to the uneducated eye look flat, but it contained multiple and almost invisible irregularities which the trade called "fast and loose". These were corrected with a saw makers hammer that had two faces at right angles to one another and which produced the marks shown in Figure 1.14. The sheet also had to be hammered to produce stretching of the edge and hence "tension", in order to increase its ability to return to straightness when bent. Flatness and tensioning were achieved by the smith's hammering in one place after another, and on both sides, constantly checking for the right result using a saw makers straightedge (Figure 1.13), a strip of steel with a fractional concave edge.

Hi Kees. Not sure if this is what your inquiring about.

Stewie;

-

16th January 2015, 01:10 AM #6

Member

Member

- Join Date

- Jun 2009

- Location

- Holland

- Posts

- 72

I will check out the book again, but I must say he is a bit cryptic in the technical descriptions. I have no idea what he means with the hammer faces "at right angles to each other".

-

16th January 2015, 01:31 AM #7

Perhaps this? This is the 5 pound hammer.

hammer sample before grinding.jpg

Holding this hammer in the right hand as shown in the picture it would make impressions on the saw plate that are perpendicular to the long axis of the anvil.

Kind of like this: l l l l l l

If the hammer is rotated about the axis of the handle it would make impressions like this: - - - - - -

If you overlapped the l and - strokes you could get impressions like this: + + + + + + or this: l-l-l-l-l-l

A round faced hammer on the other hand would make impacts something like this: * * * * * *

We know for sure that sawyers hammers were made for sawyers and that the twisted faces were made that way for a reason.Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

16th January 2015, 02:23 AM #8

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Rob. The strike marks shown in Figure 1.14. of the book look very similar to those that can be made by your 5 pound hammer.

Stewie;

-

16th January 2015, 03:08 AM #9

Is the book open source? The link that appears in your post above took me to the front page of the forum.

I don't have a copy and never have seen one. Something else to put on the list.

Do you think a posting a scan of the relevant figure here would fall under the 'scholarly discussion' or 'short excerpts' exemption to copyright?Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

16th January 2015, 12:16 PM #10

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Rob. Attached is a link to purchasing this book.

http://www.taths.org.uk/news/157-barley-saws

A book review was also posted on the U.K forum site.

http://www.ukworkshop.co.uk/forums/b...00-t83196.html

regards; Stewie.

-

16th January 2015, 01:41 PM #11

Hi Corneel.

Here are some sawmakers hammers.. Dogshead on the left.

This is a 200 lb sawmakers anvil, and a saw makers straight edge.

If it's any help, I can take some more detailed pictures of the different hammers..

Ray

-

16th January 2015, 02:22 PM #12

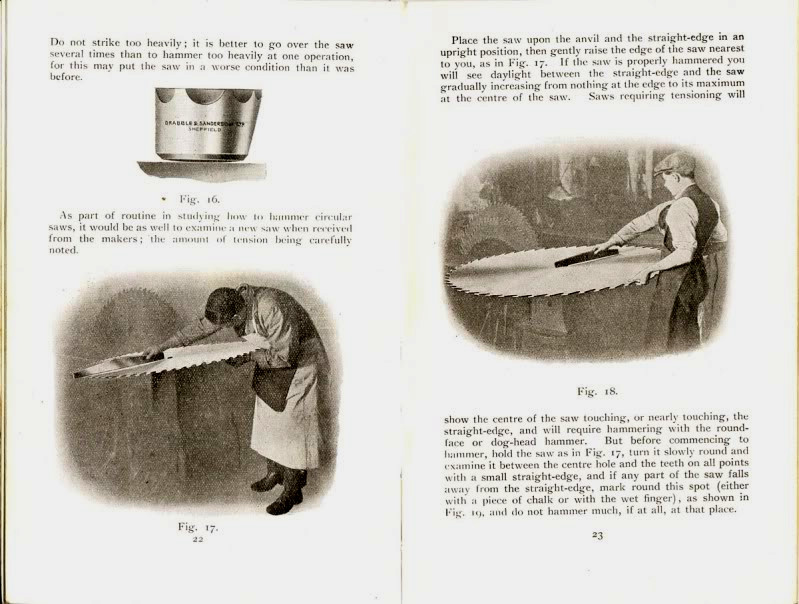

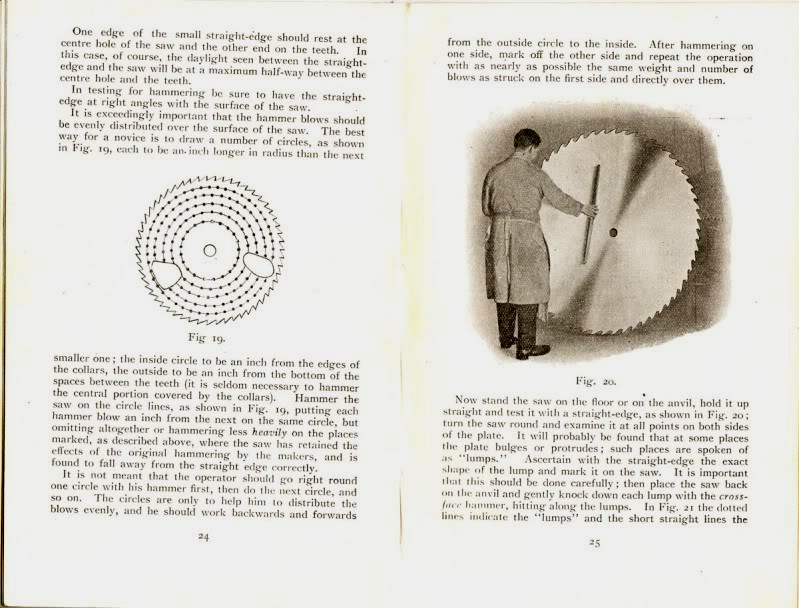

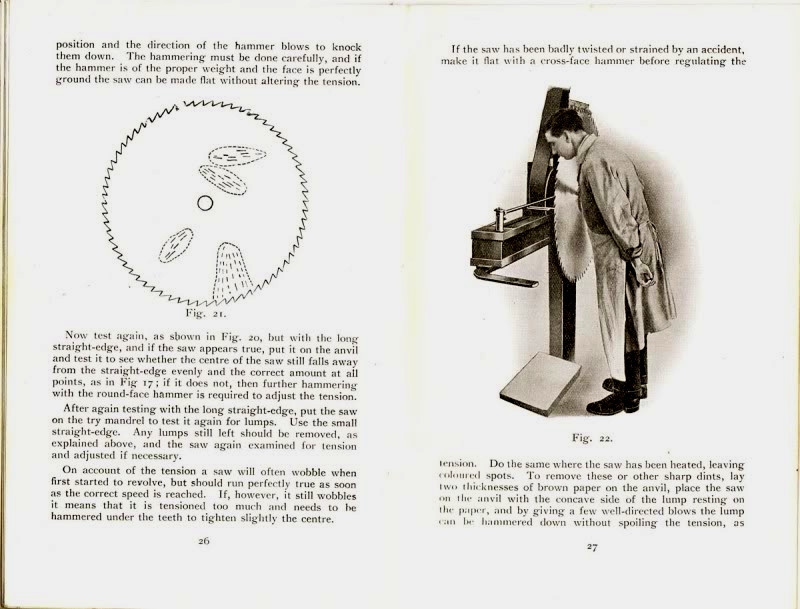

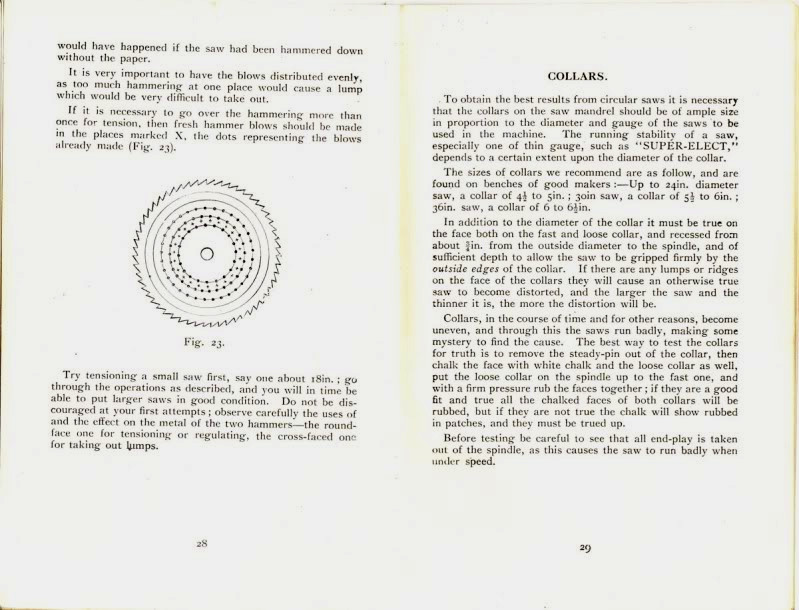

Although this mostly is dealing with tensioning circular saws, there are some good hints and techniques. And a description of the various hammers.

Note the difference between the twist face and the cross face hammers.

The pages above are from "Drabble and Sanderson Saw Doctors Guide 1925"

Ray

-

16th January 2015, 09:38 PM #13

Member

Member

- Join Date

- Jun 2009

- Location

- Holland

- Posts

- 72

That's helpfull folks!

I think I can get a reasonable aproximation when I take a normal bench hammer and shape the faces. My "anvil isn't so nice to look at, it is just a heavy chunk of steel with a nice smooth top. That'll do for a while.

And then it is just a matter of practicing. The above manual could be helpfull to determine what I am actually want to hit and how i am going to hit it.

-

16th January 2015, 10:46 PM #14

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2012

- Location

- Sydney

- Posts

- 1,503

I posted this link the other day but it's worth mentioning again.

http://www.wkfinetools.com/tRestore/...rSawBlade1.asp

In it Bob uses 2 hammers, 1 light and 1 heavy. He makes the hammer faces convex and describes their use in straightening the blade nicely.

That anvil of yours Ray looks very impressive!

Have you used it yet? Where did it come from?

-

16th January 2015, 11:39 PM #15

I've read that Bob Smalser article a few times, and tried it without much success, I need practice to get the touch right..

I got the anvil from Denman Robinson when they closed down, they used to have a shop in the city back in the early 1900's and the anvil came from there. the base is a huge solid lump of unknown timber, that came with it. The guy reckoned the timber came from a ship. Peter McBride picked up some really nice leg vises with wide jaws for saw work, and a nice collection of hammers, including a twist face.

They traded under the name Denman Lack and Robinson in the early 1900's at 333 Lonsdale Street. A search of trove.nla.gov.au turned up a few blurry advertisments... Later they changed to Denman and Robinson and were at 179 King Street, near Bourke Street in 1929.

Similar Threads

-

A few hammers

By AB515 in forum JAPANESE HAND TOOLSReplies: 16Last Post: 7th August 2014, 12:06 AM -

Dog Hammers

By Bushmiller in forum SMALL TIMBER MILLINGReplies: 0Last Post: 3rd May 2012, 10:41 AM -

Hammers

By sinjin in forum JAPANESE HAND TOOLSReplies: 24Last Post: 18th May 2011, 01:18 PM -

Planishing Hammers.

By Deesinister in forum METALWORK FORUMReplies: 3Last Post: 31st July 2009, 12:58 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote