Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 211 to 225 of 347

Thread: Hardening of sawplates

-

3rd February 2015, 12:47 AM #211

This is somewhat off-topic but it does relate to my reference to refuseniks made above. http://bos.sagepub.com/content/71/1/33.full.pdf+html

Here's another discussion: http://www.ucsusa.org/sites/default/...f-scrutiny.pdfInnovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

3rd February 2015 12:47 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

3rd February 2015, 01:55 PM #212

Hi Rob,

Here is something, I've wondered about for years, if you are going to be hammering saw plate, what about trying to swage the teeth... I don't know if anyone has ever tried to come up with a way swaging teeth on thin plate?

Ray

-

3rd February 2015, 10:09 PM #213

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Ray. I found this on swaging handsaws. https://books.google.com.au/books?id...20saws&f=false

https://books.google.com.au/books?id...20saws&f=false

Stewie;

-

3rd February 2015, 10:56 PM #214

Thanks Stewie,

Interesting read, that sort of consolidates some of what I've been thinking about tensioning saws and taper grinding. The older technique for swaging was to hammer each tooth perpendicular to the blade, so that the tooth was spread a little, and eliminate the need for set, the finished result would be a bit like taper grinding I guess. If you've got Grimshaw's book he describes it in more detail. Or look for literature comparing "swage setting" comparing it to "spring setting"

Ray

-

3rd February 2015, 11:43 PM #215

Ray,

The rakers on felling and bucking saws are swaged and the teeth of steel band and circular saws are as well but I've never heard of swaging being done on small handsaws.

http://www.ebay.com/itm/Antique-E-C-...item20f55a84c9

The crosscut saw enthusiasts also use rolling for tensioning (http://www.crosscutsawyer.com/viewto...&hilit=tension) so I'm thinking about using an English wheel.

Cheers,

RobInnovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

3rd February 2015, 11:52 PM #216

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

Hi Ray. The following information is contained in the book Standards And Specifications For Metals And Metal Products; March 1933. Detailed in Figure 748 is the recommended min/max saw plate gauge for backsaws. (Click on the +magnifier to enlarge.) Its a much heavier gauge to that being used today by my most modern saw makers. https://books.google.com.au/books?id...20saws&f=false

Stewie;

-

4th February 2015, 01:09 AM #217

Evenfall Studios has PDF's of a couple of Grimshaw's books posted. http://www.evenfallstudios.com/woodw...s_library.html

Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

4th February 2015, 10:00 AM #218

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

The primary reason I dont like using 0.015 saw plate. stiffness of a piece of metal is proportional to the cube of the thickness. Thus, a 0.020" blade is more than twice as stiff as a 0.015" one.

Stewie;

-

4th February 2015, 10:10 AM #219

Now for even colder. I went out this morning and bought some liquid nitrogen. A safety note - don't mess with this stuff if you don't know what you're doing! PPE is a must. Nitrogen does not support life so if you have this in a confined space you can easily suffocate yourself. See: en.wikipedia.org/wiki/Inert_gas_asphyxiation

It is also extremely cold and can easily freeze your body tissues. See: http://abcnews.go.com/Health/liquid-...ry?id=17425885

Okay, first the nitrogen:

This is a liquid nitrogen Dewar. It is the only way to store and transport cryogenic liquid nitrogen. Do not use a thermos bottle or some other improvised insulated container for storing liquid nitrogen - you'll be sorry if you do.

These are cryo-gloves. They are specially insulated and specifically designed for handling cold stuff. If you don't have a pair don't do this work.

This is my cryo-treatment chamber. This is just a Styrofoam cooler with especially thick sides but again, it is designed for cryogenic storage. A regular cooler might break and spill liquid nitrogen all over you so don't use them.

Into the cooler I put a soft foam block. This is to hold the metal above the surface of the liquid nitrogen. Immersing the metal directly into the liquid nitrogen can cause it to crack or shatter - could be dangerous.

Next I slowly pour some liquid nitrogen into the cooler block. I say slowly because the nitrogen is at -196 oC and the block is at ~20 oC and when the very cold nitrogen hits the relatively very hot cooler it boils causing liquid nitrogen to splatter all over the place. Very dangerous - I wear a face shield and an apron to keep it off of me.

After the bubbling and boiling has largely ceased I carefully placed the steel samples on top of the foam block while wearing the cryo-gloves to protect my hands. Then I placed the cover on the cryo cube and waited thirty minutes.

At thirty minutes I pulled off the cover and because the atmosphere inside the cube is so cold the ice mist has settled and the gas in the cube is clear. Here they are after warming up to room temp.

Now for some hardness measurements.Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

4th February 2015, 11:22 AM #220

Here's the hardness results.

Again, it looks like the cryotreatment is relieving stress associated hardness but is not decreasing the effect of hammering relative to un-hammered steel. The effect on scratch resistance is a question for another instrument however the literature supports the idea that scratch resistance will improve.Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

4th February 2015, 12:16 PM #221

Hi Rob,

Interesting experiments...

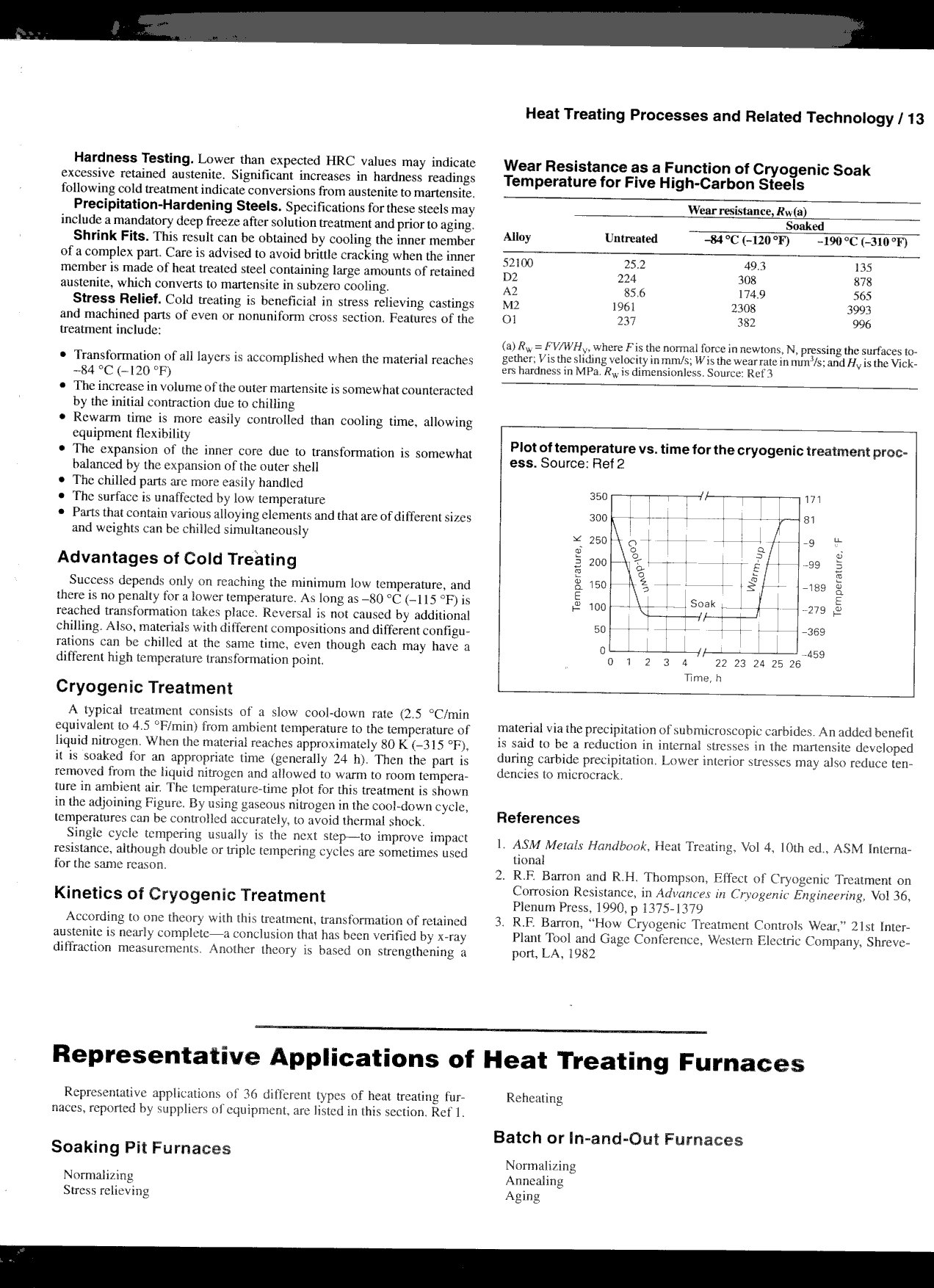

I don't have a lot of literature on cryogenic soak treatments, but the little I have suggests that you will get a significant increase in wear resistance for high carbon steels. One thing I do note is that they recommend a slow cool down, 2.5 C/ minute followed by a 24 hour soak.

Ray

-

4th February 2015, 12:59 PM #222

Hi Ray,

Is there any information you can post or is it copyrighted? The wear resistance is what I'm really after - all of the sources say that scratch resistance increases, in some steels quite dramatically. As far as slow cooling, well I wish I could do that but such equipment is beyond my saw budget.

As to liquid nitrogen hardening I have a reference that shows that maximum effect is achieved in 30 minutes. I don't remember which of the references posted above is the correct one but it is there.

Another interesting observation that I think is in this data is that the 1095 steel has a fair amount of built in stress as it comes from the factory and the cryogenic treatment seems to relieve it.

The cryogenic treatment does not apparently diminish the effect of work hardening in the areas struck with a hammer but in the adjacent stretched areas it seems to reduce the apparent hardness. This leads me to the supposition that the hardness of 1095 is due to two effects: Real or inherent hardness and stress or strain hardness.

How these factors are important in saw cutting performance is still a mystery.

Cheers,

RobInnovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

4th February 2015, 01:11 PM #223

Hi Rob,

I scanned that page, for a 1000 page book, there's precious little on Cryo, I suspect there must be another, better reference book.

Ray

-

4th February 2015, 01:43 PM #224

Thanks for that Ray.

The information on cryo treatment seems to be fairly thin compared to heat treating methods. If you're interested check out the theses I posted above, a lot of new info there.

Not a lot is known definitively about the mechanisms by which the effects of cryo treatment are achieved. That hasn't however stopped those willing to experiment. The firearm hobbyists are very enthusiastic about cryo treatments, improvements in accuracy, decreases in chamber pressure and very significant reduction in metal fouling (scratch resistance?) are noted.

For the specimens I looked at the cryotreatment did not induce any visible physical distortion. Now I need to make up some insulated tanks for treating saw blades...

Cheers,

RobInnovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

-

6th February 2015, 08:08 AM #225

I've got to build an instrument to do more controlled work but the cryo treated samples appear to be significantly more difficult to scratch than the raw material.

Innovations are those useful things that, by dint of chance, manage to survive the stupidity and destructive tendencies inherent in human nature.

Similar Threads

-

Hardening & Tempering

By Dovetail in forum HAND TOOLS - UNPOWEREDReplies: 6Last Post: 8th February 2014, 11:07 AM -

Case hardening

By Pete F in forum METALWORK FORUMReplies: 11Last Post: 18th November 2011, 10:05 PM -

Induction hardening

By morrisman in forum METALWORK FORUMReplies: 5Last Post: 2nd October 2011, 09:59 AM -

brass hardening

By Eldanos of KDM in forum HAND TOOLS - UNPOWEREDReplies: 14Last Post: 8th July 2010, 12:56 PM -

Timber hardening

By boris in forum FINISHINGReplies: 1Last Post: 31st January 2004, 11:01 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote