Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 601 to 615 of 709

-

30th November 2013, 06:47 PM #601

Deceased

Deceased

- Join Date

- May 2008

- Location

- Australia

- Posts

- 2,357

-

30th November 2013 06:47 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

30th November 2013, 07:42 PM #602

From a practical point of view, yes, but when you are putting in lots of effort on a tool, surely you want it to look as good as you can make it, so in this case I would opt for looks first.

Polishing the steel could look fine, but it won't keep its shine for long, which I suppose is why the Two Lawyers favour stainless on their saws...

Polishing the steel could look fine, but it won't keep its shine for long, which I suppose is why the Two Lawyers favour stainless on their saws...

Peter, I don't want to rain on your parade, but be careful of those bolts! Note that it says brass colour, & they come in two colours, the other being silver. That suggests to me they are not brass, & quite likely aluminium, which is what a good number of these are made from (but I may be quite wrong, it's just a feeling brought on by the look of them & the price...)

I used to use the brass 'cutlers' Chicago bolts that Lee Valley sold, on my small saws. They are very nicely made, and the un-slotted side has a serrated collar to lock into the handle, so they are easy to tighten & undo. But like all Chicago bolts I've seen, they also have a very short threaded section, so you are restricted to a fairly precise thickness of handle.

The bolts from Thomas Flynn strike me as a pretty good deal at $2.80 each. They have serrated shoulders so they lock in, and a fair amount of thread, so should fit a reasonable range of handle thicknesses. They have an advantage over the recessed type of bolt & split-nut we used at the workshop, in that the heads are designed to sit on the handle, so you only need to drill one size hole, and don't have to bother with juggling drill bits or buying special bits.

Cheers,IW

-

30th November 2013, 09:36 PM #603

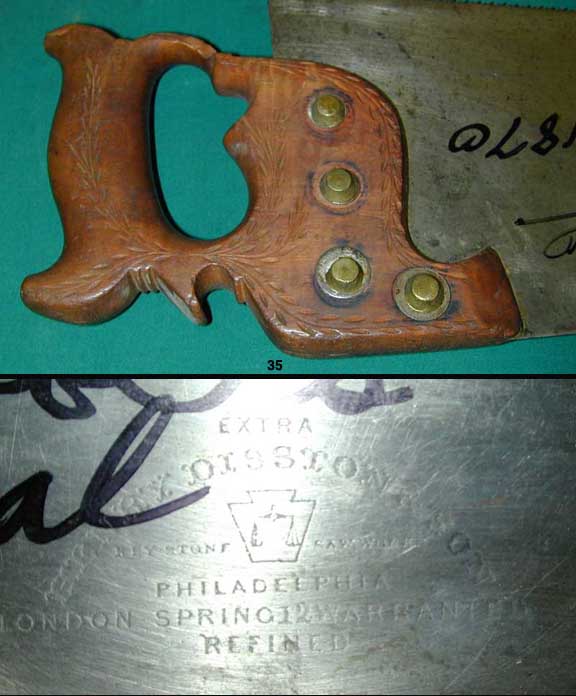

Ok I present exhibit 1.2sw

This is the saw I've been working on .

And I'm really just trying ideas playing around a bit like a prototype here .

Over all yes I like it.

But the finish needs more work ie I need to learn to be patient there .

The brass back I would do the same ,but next time sculpt the back a bit more and do some more file work there maybe a vine pattern similar to a fancy knife. But am happy with the timber infill reminds me of infill plains.

The fit of the back to the handle still working on that one .

The saw bolts yes and no .

Ok with regard to them the next ones on the drawing board(lathe actually).

Will be plain button head very slightly domed max one mm there with two small holes for a small twin pin driver in to to tighten up much like how you tightened a 4 inch grinder tho of course on a much small scale .

The thread insert to be threaded on the out side as well to fit a corresponding thread in the handle .

All metal work to be the same maybe stainless steel.

An less some one has some platinum to throw my way lol.

Your remarks criticism points of interest most welcome .

-

1st December 2013, 12:49 AM #604

Thanks for all that info Ian,

Yes, it says colour but the description below it does say made from brass.

I know they make alloy ones as well, usually for papercraft stuff.

There is a paper arts store in blackburn road here in melbourne that sells brass as well as alloy ones, but not usually in the length you want but I have used them for small carving knife handles.

A 5mm thread length isn't that hard to accommodate for in handle thickness, as you said you've used them before.

You usually get more thread on nut side so if its a smidge too long you can file a few mm off and still get the full 5mm of thread for the screw to use.

Apart from the Blackburn information given (and they do have the parts) and I've heard of Lee Valley the people who came to the saw workshop did not get anything to tell them where to get any parts from if they wanted to make stuff afterwards.

So I've been looking around for parts.

Did find Pferd after reading the great file review doc and got some files from them.

Planemaker did send me a message on a source of nuts but still 12 bucks a set plus 12.50 postage.

Dale also set me the info for the home made nuts web page which I could do and is a possibility.

It was only 2 pages back that I got raked for putting in details about dawbons for spring steel, it was only at that point I got told what rating steel I needed and you can't get it in Australia, because the only thing I got told at the workshop was "Spring steel".

I also put up the George White website earlier for brass as I know they sell in quantities I can use, glad I got that part right.

The bolts from Thomas Flynn strike me as a pretty good deal at $2.80 each.

Prior to now I had absolutely no idea Who or what a 'Thomas Flynn' is but a search of the web found "Thomas Flinn & Co"

Just in case anyone else wants to check it out here's the link Thomas Flinn & Co. Saws - Accessories, After care and sharpening

Worst part of looking for them is one lot call them "saw screws" others call them "saw nuts". I've seen other names that made no sense to what it was,

'Chicago screws' although not the same are usually called chicago something (screws/bolts/fasteners), so just as bad in naming conventions.

I have ordered 4 more saws from Dale but after that I still need to find sources for materials and hopefully I'll learn some more info as this thread goes along but I don't have all the knowledge of places that provide the info and the parts.

Yes, I search the web (and within the forums) for information, and I do read whats on them but it will take time to find them and read them and get to whats useful.

Peter

-

1st December 2013, 03:04 AM #605

I feel the same way about the one side having a smooth and neat look about it while the other side doesn't. I've never been a fan of split nuts just for that reason. A screw driver slot is ok, because you need some way of tightening the darn things.

I understand that what you intended with the pictures was to demonstrate a different type of saw screw and method of attaching a handle to the saw plate. I'm one to stray away from the traditional common methods and experiment with new and different ways of doing things. My hat is off to you for doing exactly that. I like your concept of using a threaded metal spacer tube and screwing the screws in from both sides. What you did there required some thought on your part to take a totally different direction with the screw thing. I really like the low cost compared to specially machined parts that are understandably expensive.

Here's a thought that relating to your "fine tuning" that might produce a more traditional look and still use your spacer/two screw method. Use a brass screw on the left side that is smooth, without a slot or indentation for a screw driver that fits flush with the wood. I even like screw heads that are a little proud of the wood. Screw it into the spacer first, then insert the screw and spacer as one piece through the handle and saw plate. Make it a tight fit so it won't turn, then screw a slotted brass screw into the other side. If the screw on the right screws easily into the threaded tube and the other piece is tight, it won't turn as you tighten the screw on the right. Use a drop of light oil on the threads.

I really like your concept and I intend to use it on my next saw handle. Thanks for sharing the idea....

Here's another non-traditional screw design I used on my last backsaw experiment, but you need a metal lathe to accomplish it... It incorporates the use of Allen head screws. The saw plate and back and a funky handle was purchase from Home Depot not far from where I live. The saw cost only $10.00. I rehandled it using Black Walnut.

IMG_3085.JPGIMG_3086.JPGIMG_3069.JPGIMG_3088.JPGIMG_3053.JPG

Take care,

Marv

-

1st December 2013, 03:25 AM #606

Wow, now there's a saw with some innovation...

I like what you did with the back, with the infill. Nice touch. However, those horns are just a bit too far outside that proverbial box for me. I'm afraid I might try to pull nails with them.

The screws are a bit of a detraction, but I still like the basic concept.

Everything else about the saw is nice to look at.

Marv

-

1st December 2013, 08:42 AM #607

I really like the idea of decorating the spine, you've started something there, for sure. Can't quite get with your latest handle though - those claws just look downright unfriendly, not to mention fragile! However, the main reason for making your own tools is to make 'em how you like them, so more power to your elbow for lashing out. Just remember to put plenty of effort into the fangs, now you have the claws sorted...

I don't get the point of threading the insert, it will help, but won't lock securely if you use two RH threads, because tightening the screw will undo the insert - or am I missing something relevant?

I'm not wedded to any particular form of saw bolt, myself, so it's good to see people trying alternatives. The plain headed bolts & split nuts simply offer a way of keeping the metal fasteners neat & flush with the surface of the handle. If you experiment with more decorative fasteners, remember it's annoying having edges sticking out, especially on the side where you index finger sits. Domed heads give finger-friendly surfaces and are simpler to install, but more complex to make on a basic metal lathe. I have tried doming the split nuts & bolt heads, and that can look ok, but the only way I can make the dome shape is with a file, & judging the shape by eye. My years of wood-turning help, but you've got to be pretty accurate, or it shows. You can't detect a fraction of a mm difference in table legs, but you can see it on two bolt heads 10 mm apart, & it's not easy to be so consistent. I've made some as replacements for lost screws on a couple of saws, but wouldn't use them routinely, except for very special jobs where the plain heads just don't cut it.

There's still lots of room for experimentation with decoration - all power to your elbow, keep the creative juices flowing, it makes us all think!

Cheers,IW

-

1st December 2013, 09:37 AM #608

I've just be informed by powers greater than all of us combined

That they are just bolts stop being so anal

What's your problem god your so fussy !!!

Must I constantly be surrounded by infidels

Can they not see the good I am trying to accomplish for the sake of all humanity

Ok back to Sunday morning coffee I'm off the soap box lol

-

1st December 2013, 10:22 AM #609

Only one thing comes to mind when looking for things to provide comment on. Although the curves on the brass are visually pleasing I am wondering what they may do during a cut? I tend to align things during a cut so I have a few parallel lines as a visual aid so I am not sure if those curves might put me off a little. Anyway, minor point and I wouldn't know for sure unless I tried it.

-

1st December 2013, 11:47 AM #610

Just gotta say ... You started this thread not knowing how the event would go.

I talked to you at the Melbourne show and you pondered how it would go and if you would cover expenses.

You did well and this seems to be one of the most supported threads on the forum ATM

Big thumbs up and if you do another one I hope timing works for me to attend

Dave

The Turning Cowboy

-

2nd December 2013, 02:02 PM #611

Member

Member

- Join Date

- Feb 2012

- Location

- Brisbane

- Posts

- 93

-

2nd December 2013, 03:01 PM #612

IanW ... first I might remind people that in the past there have been ?? truncated conical ?? boltheads that look kinda cool on some old saws

... but regarding domed boltheads ... don't you think it could be put in a lathe or drill-press, roughed with files, and then a single "mould" made in jarrah or whatever that could be charged with SiC or diamond paste or something to get them all down to a uniform end result? Maybe a series of them in different sizes and with different grits progressing towards an end result ... assuming someone wanted to go to the trouble?

Also I'll note that your standard D8 handsaw had, at least on the 26" version, 5 bolts with the first one undersized to the other 4.

I'm guessing without checking ... probably the same story on the 4-bolters.

Cheers,

Paul

-

2nd December 2013, 05:10 PM #613

-

2nd December 2013, 05:58 PM #614

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Dec 2005

- Location

- Sydney

- Age

- 79

- Posts

- 647

-

2nd December 2013, 06:20 PM #615

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Dec 2005

- Location

- Sydney

- Age

- 79

- Posts

- 647

DSCF7930.jpg

The saw made at the workshop (and finished at home). This was the first time I had used a scroll saw, and whilst fairly slow, it is not too difficult to get a pretty reasonable outline, even for an uncoordinated person like me. I consider this a ‘prototype’, there is definite room for improvement. The handle broke during the mortise cutting process (dodgy vice), but seems to have gone back together ok. The She Oak Dale provided seems hard and brittle, so I might have been banging on the chisel a bit hard as well. Handle size and shape are interesting – I think I prefer a fairly flat end shape, and a relatively wide handle (fairly long fingers); using the Blackburn handle sizing guide, my measurement is 4” or large. However, using the large handle template, the resulting handle is a bit too big, the bottom horn does not ‘snuggle in‘ and I now making another one using a Medium sized handle template with enough beef at the bottom of the blank to get the size just right. Finish is 3 coats of Blonde shellac and a cost of clear wax. Final thickness 15/16th" which I find comfortable.

I believe the wood is She Oak, this is a blank cut from same plank, have I got the species wrong?

DSCF7931.jpg

I found the carvers chops handy for shaping the handle.

DSCF7929.jpg

This saw is unset, and when freshly sharpened cut very well indeed, but as Isaac mentioned in a message, I think somewhere back in this thread, the saw quickly becomes tougher to push. Nevertheless went 0.75” through 1.75” pine without too much protest. I guess once the burr is gone…

Looking at making some more saws, however I am finding quarter sawn timber hard to find. I have acquired some Silky Oak and a scrappy piece of American Walnut. But rummaging through my accumulated timber pile I found only an offcut of Huon Pine that was partly QS (that would make 2 saw handles) – I seem to recall that RayG had a Huon handle break, but this scrap has limited use anyway, so will give it a go.

Cheers

Peter

"Form follows failure" Dornier

Similar Threads

-

workshop needed in Melbourne

By zceren in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 0Last Post: 7th June 2012, 12:28 PM -

Anyone know of workshop space to rent in melbourne?

By mandodan in forum WOODWORK - GENERALReplies: 1Last Post: 18th March 2009, 05:42 PM -

Workshop hire in Melbourne?

By Pra33 in forum WOODWORK - GENERALReplies: 9Last Post: 26th June 2008, 12:36 AM -

Workshop space needed - Melbourne

By monoman in forum WOODWORK - GENERALReplies: 6Last Post: 19th January 2005, 08:59 AM -

Public workshop in Melbourne?

By Tracey in forum WOODWORK - GENERALReplies: 4Last Post: 21st August 2003, 01:29 PM

Likes:

Likes:

Reply With Quote

Reply With Quote