Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 18

Thread: 1945 Dewalt Radial Arm Saw.

-

7th January 2016, 12:24 AM #1

1945 Dewalt Radial Arm Saw.

1945 Dewalt Radial Arm Saw.

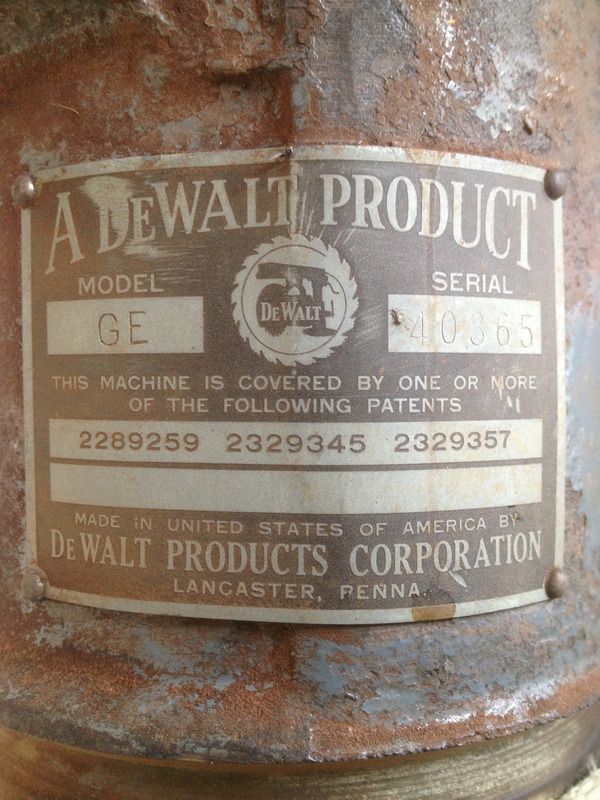

I picked up a Dewalt RAS last year, now that the holidays are here I've had some time to get it in the work shop and clean it up.

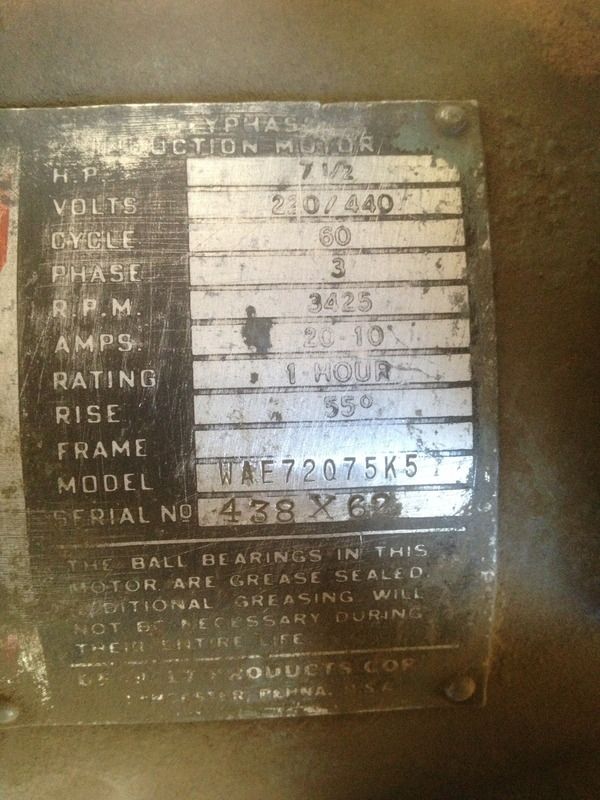

Its a real neat old thing, really big too, 16 inch blade, 7 1/2 HP motor very well made in the US.

Every thing seems in order, good bearings on the slide, motor is quiet, no cracks in the cast or striped out threads on locking levers, good condition for its age.

I have liked these saws ever since I was a young apprentice carpenter & Joiner, the first one I ever saw was at Mordialloc Timber near the station, all gone now..

Its nice to have my own after lusting after one for so many years.

Melbourne Matty.

-

7th January 2016 12:24 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

7th January 2016, 12:53 AM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Apr 2012

- Location

- Sydney

- Posts

- 1,503

Looks like new. And how were the ball bearings?

-

7th January 2016, 07:26 AM #3

Nice education. I did not know dewalt was that old.

Great work

Dave TTC

Turning Wood Into Art

-

7th January 2016, 09:57 AM #4

Bearings were very good in the motor, quiet as !

Bearings in the sliding carriage were just ok, most spun, one I had to free up a little.

The whole track system benefited from a good clean out, the previous owner had been making red gum out door furniture and the red dust was every where.

The track it self had very little wear, there is a tiny amount of play when the motor and carriage is in the start position but no play or side movement during the cut.

For an old 1945 machine I was pretty happy with the condition, the only thing I was disappointed with, and it was purely cosmetic, was the frame had taken a hit on the L/H side front, possibly from a fork lift or something, it had been repaired well enough, just the steel is not flat there any more, a few ripples.

My plans for now are to just get it cutting with a brand new blade, see what it can do, the track bearings I will replace some time soon and see if I can get the upper cast iron arm track re machined at some stage, very tricky job, Wolf over in the US offer this service, I'm not sure who can do something like that over here, I'll talk to a good mate who runs an engineering shop in Dandy.

Melbourne Matty.

-

7th January 2016, 10:19 AM #5

-

7th January 2016, 10:58 AM #6

One of them would go nice in my workshop when its up and running

Dave TTC

Turning Wood Into Art

-

7th January 2016, 04:53 PM #7

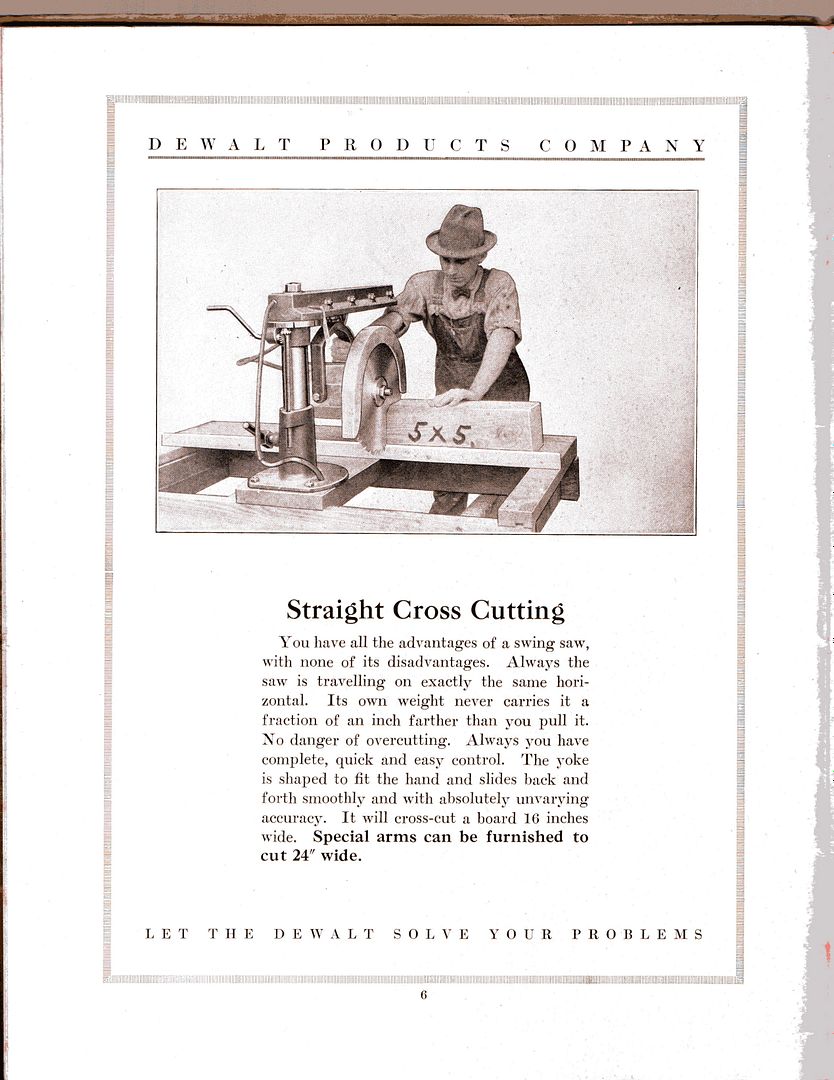

Lovely machine Matty, and that early catalogue is a treasure, what power machine is it describing? I'm not sure about plugging 7 1/2Hp into an ordinary light socket.

-

8th January 2016, 07:46 PM #8

Hi Sion, its great to see you posting here when you can, its a nice slow pace on this side.

The Dewalt saw is three phase power, so yea, not a little light socket.

Moved it all in position, started welding up a side bench and cleaned up (or more so rebuilt) the saw stop set up.

Just have to work out now what type of material to use on the tops the for timber to slide across on, traditionally timbers such as Vic Ash were used in sawmills for docking bench tops.

Melbourne Matty.

-

13th January 2016, 07:18 AM #9

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Matty,

That has come up looking really nice, with 7.5HP she is a beast, looking forward to a video of it cutting (if you get a chance). I really like those stops, are they original to the machine?

For the table top, perhaps some MDF, I know how you like that stuff

Cheers,

Camo

-

13th January 2016, 04:36 PM #10

China

China

- Join Date

- Dec 2005

- Location

- South Australia

- Posts

- 4,474

Nice machine, nice clean up, most people think I'm behind the times when I tell them I have a radial arm saw, (been trying to find a set of stops like that for yonks)

-

14th January 2016, 06:42 PM #11

Intermediate Member

Intermediate Member

- Join Date

- Aug 2015

- Location

- Australia

- Posts

- 31

Just lovely !!

-

15th January 2016, 02:32 AM #12

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2011

- Location

- Murray Bridge SA

- Posts

- 3,339

-

15th January 2016, 01:32 PM #13

Senior Member

Senior Member

- Join Date

- Feb 2014

- Location

- Bne

- Posts

- 383

The Delphi forums they would be in awe of that beast, what a find. I have a 1960's 12" model and it is great.

Something that worked for me is a solid rubber bung strap attached to the shed bearer and the saw carriage to stop any chance of the saw climbing towards you with bigger stock.

Very nice.

Well done

-

16th January 2016, 08:56 AM #14

Thanks Cam, I'm just not so sure about MDF, just not a big wrap for that stuff, it doesn't like water for some reason...lol

I will probably go a traditional hard wood ladder frame construction, I have seen this in some timber yards many years ago, the spaces between make it easy to move the timber because you can place your hand around and under the stock easily.

Melbourne Matty.

-

16th January 2016, 09:02 AM #15

Hi China, thanks for your comments !

China, those stops believe it or not can be made up quite easily, I have a pattern/design of one that could easily be laser cut, plasma cut the shapes out (inexpensive these days) and assembled.

Its a very simple design and there is not much to it. I can provide some pictures if you like ?

Melbourne Matty.

Similar Threads

-

dewalt radial arm saw

By racyrabbit in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 17Last Post: 2nd October 2011, 01:24 PM -

dewalt radial arm saw 125 or 320

By dtmiskin in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 0Last Post: 28th September 2011, 09:40 AM -

help please with dewalt radial arm saw

By scamp in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 4Last Post: 22nd March 2011, 10:13 PM -

Dewalt 740 radial arm saw

By johnnyo1934 in forum JOINTERS, MOULDERS, THICKNESSERS, ETCReplies: 5Last Post: 8th September 2008, 11:55 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote