Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 46 to 50 of 50

Thread: The Square Head Thread.

-

4th April 2015, 09:13 PM #46

Hi Rod,

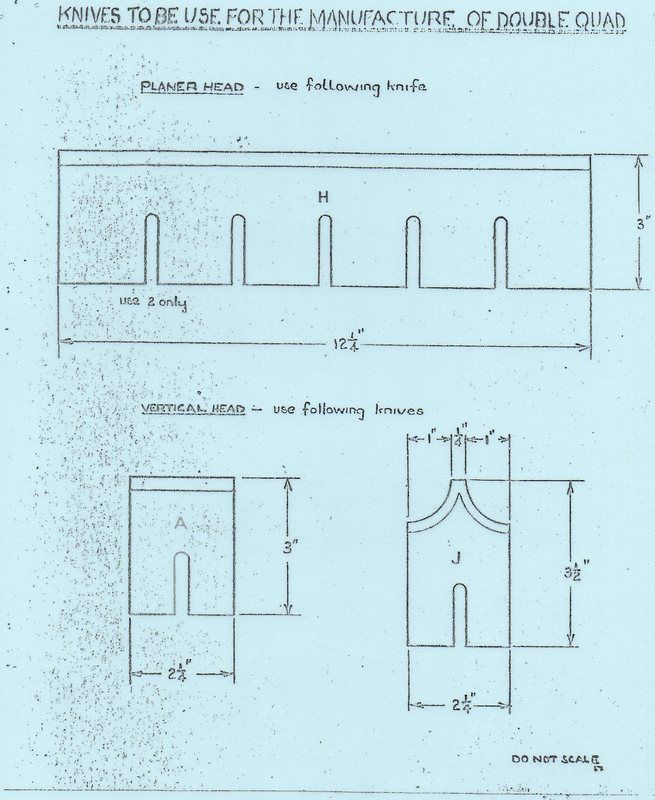

Jeffwood thicknessers were designed to also run small mouldings, it actually mentions this in the users manual.

Cutters can also be ordered from Jalor Tools PTY Ltd. - About - Google+

Here is a page from the manual showing an example...

Melbourne Matty.

-

4th April 2015 09:13 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

4th April 2015, 09:26 PM #47

-

7th April 2015, 10:54 AM #48

I was told by my machinist (tool and Die ) friend that EDM is the only safe way to cut brazed tooling with out damage to the braze weld from heat. the cutting is done under water and its said to be

better than grinding i am told. I asked because i am having some old square head tooling that is carbide brazed to mild steel 1/2" cut to make cutters for the trenching Heads

great thread

jack

English machinesAll tools can be used as hammers

-

12th April 2015, 04:24 PM #49

2) adequate support for the cutter , cont..

Thought I would push on with this thread, I have a bit of interesting stuff to show and felt the need to start with some talk on Bolt condition.

The Bolts that hold the cutter in place are probably the most crucial aspect to the function of a square head cutter.

I know, I have gone on a bit about "bolt condition' but for me it can be the start of most square head cutter accidents.

Over tightening can be a big oversight upon setting up, yes, there is the need to have cutters well attached to the head, but putting a length of water pipe over a spanner for leverage is a big no, it puts way too much pressure on bolts.

For tightening up bolts a 300mm long spanner with enough physical force is plenty, any more is over kill.

If needed, this can be checked with a torque wrench set at around 100 to 110 lbs, but I will always prefer to hand tighten, its a feel thing.

New bolts are the best, its like putting on a freshly washed and ironed shirt, I guess what I am trying to say is that its like most things, all bolts will basically have a shelf life, how they are cared for will extend the life of the bolt, over tighting and abuse will only bind and stretch the thread leading to a shorter amount of use.

Never oil the threads nor soak bolts in oil, keep dry and rust free, if a lubricant must be used then graphite is acceptable.

A good test for threads is to remove the nut from the bolt and turn it over/upside down and if it threads back on to the bolt the condition is good, if not then the thread has been compromised.

Below are some great examples of over tightening and wear on threads.

These are dovetail bolts from a larger square head, the top bolt is stretched enough to angle the thread away from the bolt, where as the bottom bolt is still in reasonable condition.

These are bolts from a square head thicknesser, and again the top bolt is stretched and shows visible signs of distortion, where as the bottom bolt is still quite usable.

And the last example, these are from a Jeffwood thicknesser, very small bolts and easily over tightened. the top example is unusable, the bottom is still in reasonable condition.

Melbourne Matty.

-

12th October 2015, 01:57 AM #50

Novice

Novice

- Join Date

- Mar 2009

- Location

- Perth, Western Australia

- Posts

- 20

Sorry bump and old thread, but wanted to share some second hand experience.

Someone visiting my shop in 2004 saw my old jointer and held up his hand. It looked just like the pic from the Oliver catalogue Matty posted earlier in the thread, only with just slightly more of each finger left. My jointer had a round head which was hidden from view and I was able to confirm that his accident was with a square head.

I have seen one square head jointer in person - was in an old line shafted shop that had not be used in a long time - many babbitt bearing machines. The jointer was an 16" and I'm pretty sure from mainland Europe. Funny thing, there was also a very early 12" Barker jointer there - round head of course - and was the newest machine in the shop. It appeared that even the shop owner thought exposed belting everywhere at below waist level was OK (the belting ran under and across the floor), he was sufficiently afraid of the square head jointer to buy something safer.

- Jayeson

Similar Threads

-

Attaching thicknesser blades on a square head

By woodlogic in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 3Last Post: 17th April 2015, 12:13 AM -

thread tapping head

By tanii51 in forum METALWORK FORUMReplies: 4Last Post: 15th August 2010, 06:58 PM -

Where to get big square-head bolts?

By Gunnaduit in forum WOODWORK - GENERALReplies: 16Last Post: 21st August 2009, 08:53 PM -

Square thread

By pommyphil in forum METALWORK FORUMReplies: 12Last Post: 10th August 2008, 11:27 AM -

Thread on stainless steel square bar

By SBartleet in forum METALWORK FORUMReplies: 13Last Post: 30th October 2007, 11:47 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote