Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 50

Thread: The Square Head Thread.

-

21st March 2015, 09:36 AM #16

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Matty,

Great thread, lots of good information! I'm looking forward to seeing you expand on things when you get a chance.

cheers,

Camo

-

21st March 2015 09:36 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

21st March 2015, 11:30 AM #17

Thank you for the objective observations of square cutterheads

I personally can't see what is wrong with using them, having used some incredibly dangerous contraptions and machines in my 35 odd year careers of boilermaking, cabinet making and generally working around/with my father on properties in the west of queensland for as far back as I remember.

I will follow this thread with interest.

RobCheck my facebook:rhbtimber

-

21st March 2015, 09:49 PM #18

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

It's not that there's anything wrong with them, they're just not quite as idiot proof or forgiving of lapses in concentration as some of the newer heads. 100% attention 100% of the time (which should always be the rule anyway) or things can go very bad very quickly.

That and the noise...soooo much noise

-

22nd March 2015, 03:16 PM #19

Kuffy, Cam and Rob, thank you for your comments, its great to see folk chiming in and talking about their experiences and concerns.

I was going to push on with John's hit list, I think its a good start at least to discuss, in some depth techniques and processes.

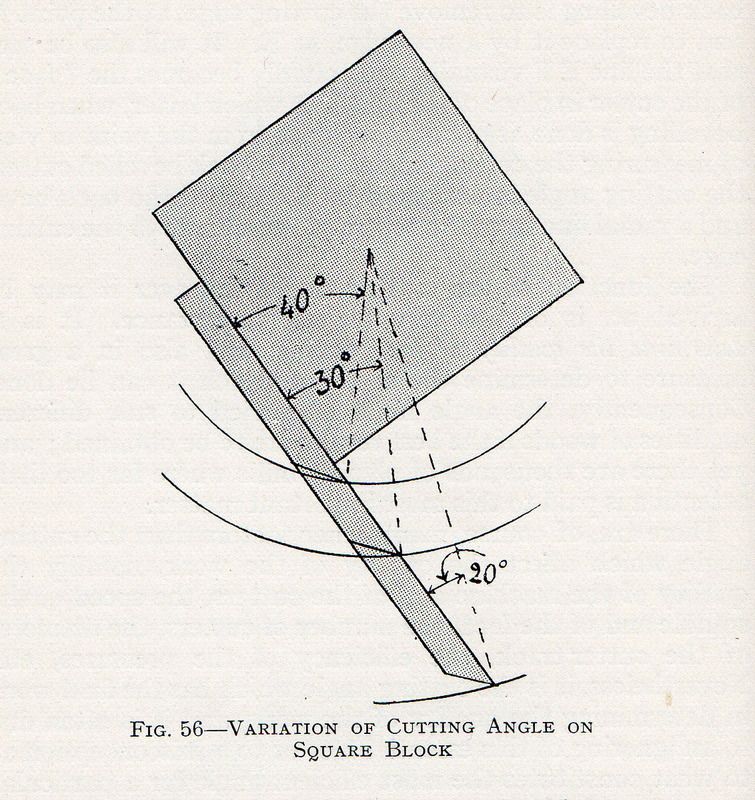

1) presentation angle of the cutting edge to the timber, and its capacity for tweaking (via projection, not grinding)

I use an old Wadkin NL grinding machine for grinding and sharpening my cutters, it cost me $300 at the time, problem was from Melbourne, I had to go all the way to Whyalla in SA to get it, what a road trip !

Its a beautiful machine and has done a bomb of cutter grinding for me over the years.

My angle Preference is set to 38 Degrees, I have found this angle to be the best for both hard woods and soft woods in general.

35 degrees is the best bevel set for hardwoods then running all the way up to 43 degrees for a longer bevel for softwoods.

Some may have a different take on this, happy to discuss it here more.

At the point of the cutter striking the timber to make the cut in theory, the longer the projection the more acute the cutting angle will be.

But the trap here is the greater the overhang of the unsupported cutter the greater the danger/risk for bending or breaking of the cutter.

Thicker cutters can be made to aid this and side braces/supports set up but over hang must still be kept to a minimum.

This all mainly concerns setting moulding machines, if I am running a deep profile with a lot of projection on cutters, I usually remove a great deal of the material prior to running, so the cutters are taking of the minimum of material and as to not load the cutters too much.

When I asked where do you start setting a cutter on a cutter block, how far out does it go? I was told many years ago that overhang and projection begins with bolt clearance.

I prefer to use bolts with a very flat nut as to give me as much clearance as possible.

Setting a Thicknesser is much easier, projection can be kept to a minimum from the edge of the block.

Here are some pic's below of my wadkin grinder and diagram of the cutting angle variation.

Melbourne Matty.

-

23rd March 2015, 02:41 AM #20

-

23rd March 2015, 02:49 AM #21

I have a 20" Cooksley thicknesser with a square head and exposed belts (previously video'd).

It doesn't get used a great deal, but it has taken some large logs through and I love that damn thing.

Talking about noise ... I much prefer it's low, aeroplane engine sound to the high-pitched scream of the lunchbox thicknesser.

But sure, if someone was giving away spiral heads ...

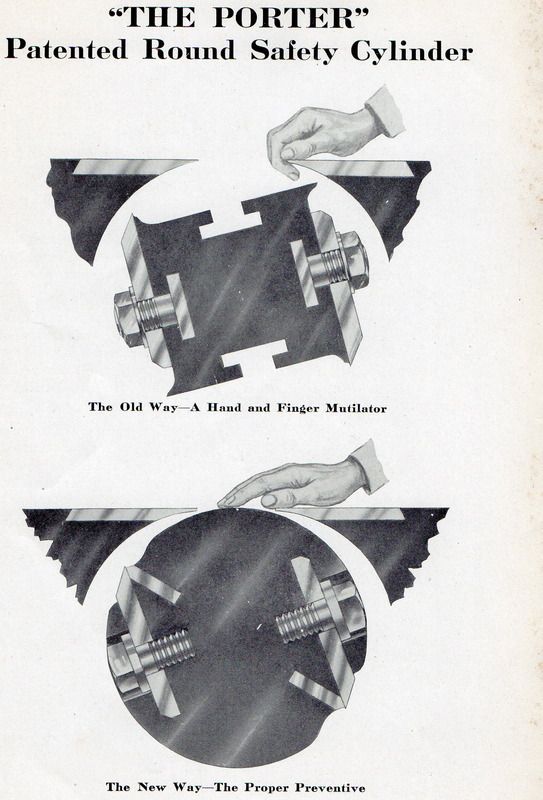

There's also the factor that not all round-heads are approved of either.

I have a 12" clamshell-head jointer that is yet to be setup ... but I have read up about the head design.

Cheers,

Paul

-

23rd March 2015, 07:09 PM #22

Paul, just keep an eye where the gent has his fingers, one cutter will take a lot more that the other, I'll stick with pregnant.

Love to see a pic of the cutter-head on your Cooksley, if you can manage it Paul, I have seen pics of your beast before, next door to you would know when to get up ...lol

Im either stone deaf or I'm just not hearing it, none of my square head machines are that loud.

One point I will emphasize on the subject of noise, is sharp blades play a big part, yes there is a lot of cutting through the air noise as square heads are not the most aerodynamic, but sharp blades will reduce much of the cutting noise.

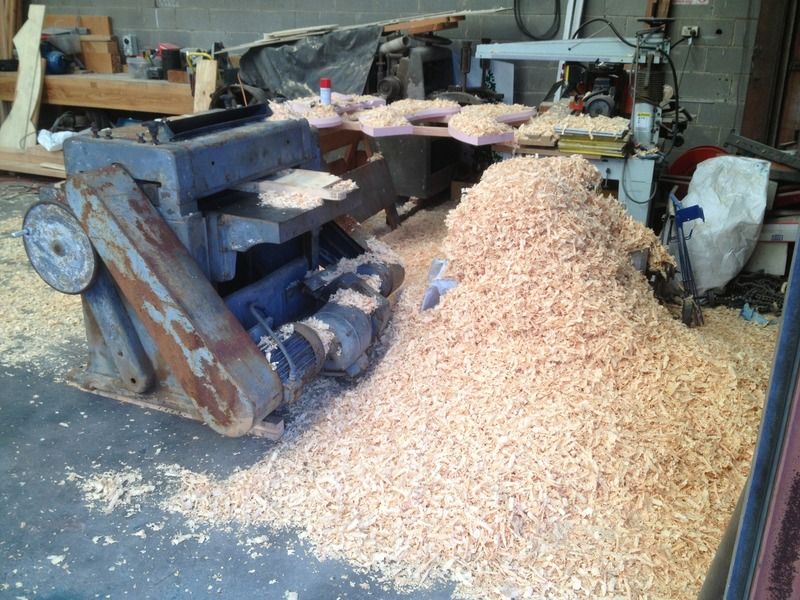

My Barker thicknesser came with the worst set of blades I had ever seen, it looked like the Previous owner had been machining red gum sleepers, and yes they were loud and blunt.

A few hours to clean up sharpen and hone, set in the machine and wow what a difference, rather than the timber being vibrated to death you could actually hear it cut, and big fluffy shavings coming out the back, just the way the machine gods intended !

Before......

After....

Melbourne Matty.

-

23rd March 2015, 07:42 PM #23

Nice pictures and thread Matt . And nice Barker , you going to paint it ?

Convoy Grey is the in thing these days they say down the Mens shed's.

I think it's the colour for when you really mean business! Like a Battle ship or a Holden

Your missus must love it when you get home , smelling of all that lovely Oregon .

I think I like the smell more than Huon in strong doses .

Rob

-

23rd March 2015, 07:59 PM #24

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

Love the dust extraction, Matty

Don't let BobL see that or he'll have a heart attack

-

23rd March 2015, 08:16 PM #25

Matt, Ive got to get around to getting cutters made for this one day soon . I know who to go and see .

Do you think because those four little cutters ( two upper and two lower) are only working end grain that it would be a different bevel angle because of that ?

Rob

-

23rd March 2015, 08:40 PM #26

Rob yes it will be painted up sooner or later, I just wanted to get it going for now, make some money with it.

But yes, it will be Grey, the colour-bond colour is "ironstone" or traditionally known as "Machine Grey"

Lately I'm smelling more like a Mechanic with all the machinery restoration going on, but yes the Oregon is a great smell.

so is Huon too !!

Thanks Elan, yes Bob would be less than impressed, but it is just temporary, Bob would have a heart attack if he saw how big the system is that we will be hooking up to.

Lets just say that every bit of flexible duct gets replaced every 6 months, as they basically get sucked apart.

Melbourne Matty.

-

23rd March 2015, 08:52 PM #27

Defiantly more of a scraping action would be better for end grain rob, the thing to watch out for on scribing cuts is tear out.

A more of an acute grind should help eliminate this, and it should hold its edge better too.

Finding cutters are not a problem either, if you know some one ......

Melbourne Matty.

-

23rd March 2015, 08:54 PM #28

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

If you're happy to have an observer/extra pair of hands for the restoration I'll happily volunteer; I've pulled a few machines at work apart for repairs before.

I wish we had an extraction system like that, we've slowly been adding bigger machines to the system and the system just can't do it any more. I've started my campaign for a larger reverse-pulse extractor instead of the vibration-clean one we have now, but I don't see it happening any time soon; I'm not even going to bother asking for an increase in pipe size.

-

23rd March 2015, 09:10 PM #29

Elan, thanks for the offer and the enthusiasm, much appreciated, I may yet take you up on it !

We have both systems, the Vibration-clean seems more reliable, as every few months the large pulse system blocks up top because of the shape of the hopper (a design floor), not the most glamorous task to clean out, but hey, as far as suction is concerned its a winner, a serious bit of kit, no leaving any tools or small children near open ducts.

Melbourne Matty.

-

23rd March 2015, 09:23 PM #30

Taking a break

Taking a break

- Join Date

- Aug 2008

- Location

- Melbourne

- Age

- 34

- Posts

- 6,127

The vibration-clean managed just fine for years with the larger chips from planing and sawing, but then we hooked it up to a 1350mm wide belt sander with 2x8" ports and now a 10" flexi hose to the CNC as well. The fine dust packs into the filter pleats and no amount of shaking gets it out; someone (fortunately not me) has to go out in a full suit and mask and blast compressed air through the filters to clear it.

Similar Threads

-

Attaching thicknesser blades on a square head

By woodlogic in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 3Last Post: 17th April 2015, 12:13 AM -

thread tapping head

By tanii51 in forum METALWORK FORUMReplies: 4Last Post: 15th August 2010, 06:58 PM -

Where to get big square-head bolts?

By Gunnaduit in forum WOODWORK - GENERALReplies: 16Last Post: 21st August 2009, 08:53 PM -

Square thread

By pommyphil in forum METALWORK FORUMReplies: 12Last Post: 10th August 2008, 11:27 AM -

Thread on stainless steel square bar

By SBartleet in forum METALWORK FORUMReplies: 13Last Post: 30th October 2007, 11:47 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote