Needs Pictures: 0

Needs Pictures: 0

Results 46 to 60 of 112

Thread: Wadkin Wood Lathes

-

13th April 2016, 11:34 AM #46

-

13th April 2016 11:34 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

13th April 2016, 11:50 AM #47

-

13th April 2016, 12:54 PM #48

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Jack,

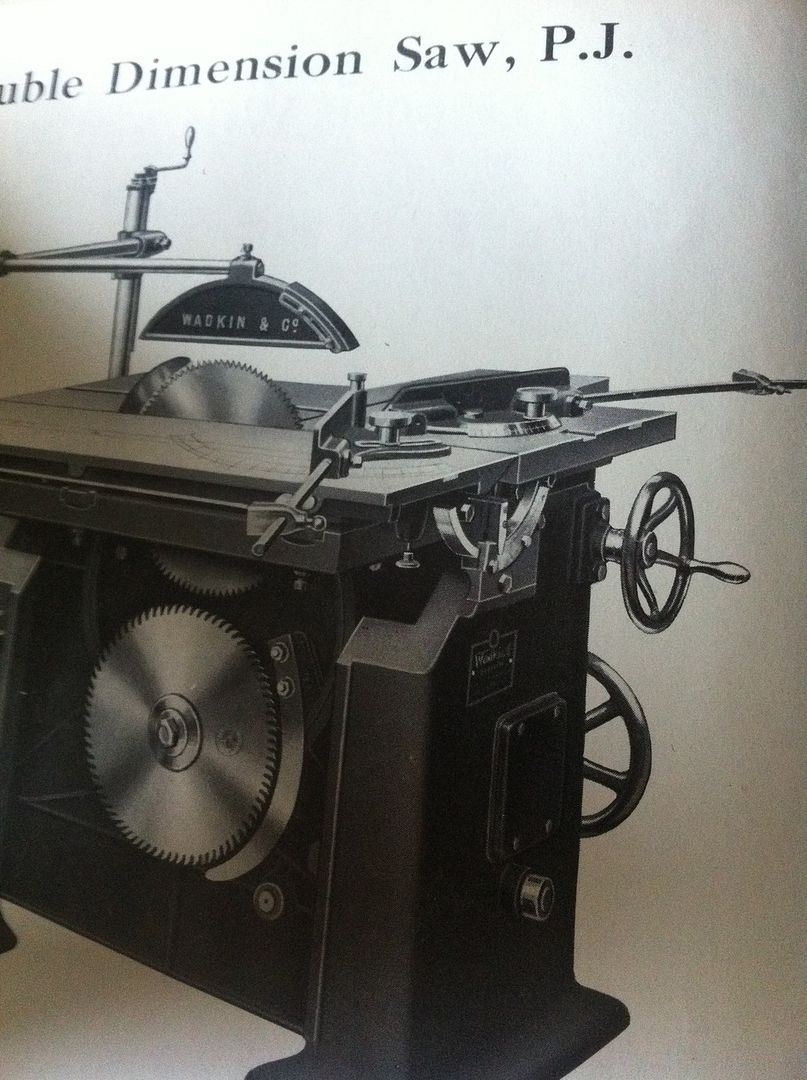

There is another complete topic that could be discussed (don't want to get Vann's post too far off track though), but here is the PJ, so it probably depends where you want your hand wheels and if you want a riving knife

The reason for asking clarifying PJ vs PL was I may have some insight for you (a piece of the puzzle perhaps, certainly no answers, but perhaps some more information) as to why you might see PL's with DC (all assumptions until proven obviously). Here is how I think the PL came about, although I make some leaps (due to lack of documentation, so this is definitely a theory at this stage). The PL to me was the direct drive version of the PM, and the PL replaced by the PK, but the PM remained for longer due to it being the flat belt option. The PM had the option of Belt drive or driven by motor off the fast pulley or "the motor is mounted in a special manner direct on the main frame".

This was a time of change, and the company was obviously trying to move towards self contained options. There was the X.A which was a 20" non tilting saw (flat belt or floor mounted motor), but there was also the A.Z.A they say in the description "This machine is of similar construction to the A.X, except that it is electrically driven with the motor mounted direct on the saw spindle". Interestingly in the description they say "the motor is special design, and is manufactured by us by one of the best-known British makers". They mention the difficulty of an A.C. direct mounted motor at the time with the difference between 50 and 60hz, "we can supply machine on 60 cycle supply also, but saw should not then exceed 16" diameter". Also around the same time their is the P.A/P.B. with the option of a Direct coupled motor drive "the motor coupled direct to the saw spindle by means of a flexible coupling". In the description they state two hurdles they faced "the only disadvantage of this drive is that the motor comes above the saw table.......it is not always possible to adopt this method of drive as the speed of the motor must always be the same as the saw spindle speed.....In the case particularly of A.C. supply it is not possible always to obtain motors of suitable speeds"

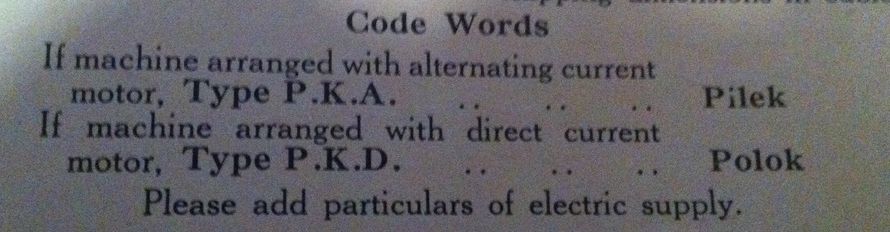

I don't know my history of the standardization of voltage and frequency, the PK definitively (at least initially) had the option of DC or AC, and perhaps the reason why DC is seen in the examples of the PL, had to do with the limitation of the size of the blade, the thickness of the motor or the availability of power options. Like I said no real definitive answer, but perhaps some more information on the hurdles Wadkin were facing at the time, both with the differing power sources locally and in their overseas markets.

How does all this tie back in to Vann's post?? Well Vann let me apologies if I have gone off track, but I thought it might help understand how the RTA came about, firstly the "A" was due to it being a time of many drive options, with the introduction of electric motors, they added "A" and "D" to denote AC or DC, adding a 3rd letter could also mean something completely different eg. "B" was added to the X.A.B. which was the boring stand for the X.A. Secondly the RTA is an example of a self contained direct drive machine.

Cheers,

Camo

-

13th April 2016, 02:22 PM #49

So, to update the list (in alphabetical order):

K.A. Propeller Boring & Recessing Machine;

K.D. Patent Strut Copying Lathe;

K.E. Automatic Propeller Shaper;

K.F. Universal Propeller Vice;

K.G. Capstan Wood Trimmers;

K.H. Wood Turning Lathe;

K.T. Hand Feed Jointer.

Cheers, the real Vann Gatherer of rusty

Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

13th April 2016, 04:42 PM #50

So are you saying that the RTA is just an AC powered RT with a direct coupled motor (like a PKA is an AC powered PK)?

If so, that would make sense if they only ever intended to make an AC version (hence the "RTA" pattern numbers) but later added a DC version (as shown in Matty's cattledog cuts). This is what Jack is suggesting. That would mean there are/were RTDs made.

I was going to argue that you are wrong, because this DC machine is classified RTA (pikkies from post 15 in this thread).

RTA148.jpg RTA148t.jpg

But then I re-read the tag and noticed the "50 cycles" and "3 phase" (well it looks like a DC machine

(well it looks like a DC machine  - I'll just go sit in the dummies corner).

- I'll just go sit in the dummies corner).

Then again, that would mean there should be CCA saws out there (for example). Does anyone know if there are?

As for going off track Camo - don't apologise. It's an interesting discussion (to me anyway). Loving it.

Cheers, Vann (the real one)Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

13th April 2016, 09:55 PM #51

Thanks camo I think you're thinking the same way I am of course you have just a bunch of knowledge I've never had Available .

Vann The AC is in all intensive purposes the CCA . if it wasn't for in AX I would've swore they were just claiming the saw to be AC powered by calling it AC. Obviously the A-line is the very first machines made after the pattern Miller and it appears that the K line was developed by government contract . This initially got Wadkin off to a good start. The catalogue cut I show is from 1915 . And I often wondered if these machines were specifically made for the mosquito aircraft that was a massive contract for the government . Incidentally the mosquito was a wooden Boomer and the fastest plane made out running the Germans .All tools can be used as hammers

-

13th April 2016, 11:06 PM #52

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Jack,

I think you are right, just curious if you had found any info on those machines being specifically part of the propeller manufacturing machines, as this is information that I had seen but not really looked closely at.

It has really been fun having you jump on the Aussie forum and talk about all things Wadkin. Thanks for sharing those 1915 cuts. After your post, I went to look for clarification on some points regarding the history of Wadkin, and it's amazing to find how foggy the past is, even when it comes to looking at what might be considered to be reference sites.

Cheers,

Camo

-

13th April 2016, 11:23 PM #53

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Vann,

Firstly let me say that is not correct, you are far from a dummy, just in case someone has not seen your work, you really do have a knack for researching your machines. Also by no means am I suggesting that necessarily all I am saying is 100% correct, I don't think anyone who has spoken on the forum can make that claim, I mean if you go back a year or so, we were all pretty much convinced that the first 2 numbers of the test number was the year, so everything should be treated as a theory until proven.

Now to try and answer some of your questions as best I can. Let me see if I can supply a bit more information to clarify what I am talking about.

Well interesting you should pick the CC as it has a bit of an interesting past which may help shed some light on your previous questions and may even help Jack in the fact that we will be going back to the A's (but hold on because we are going right off topic here).

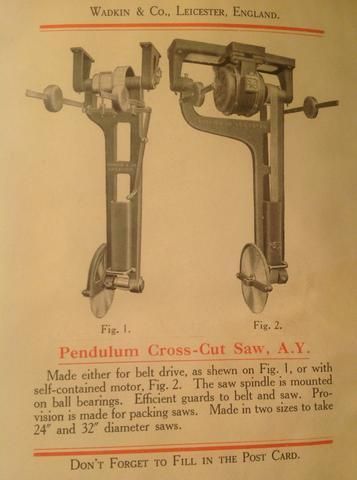

Wadkin had the A.Y. Pendulum Cross-Cut Saw

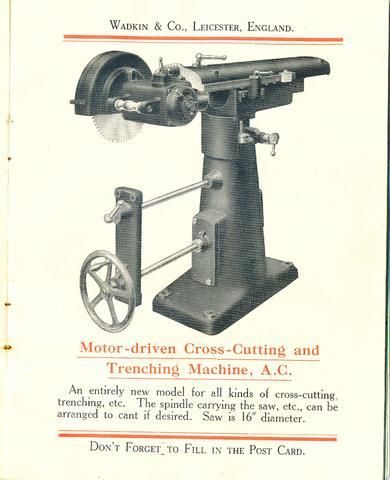

Then they came up with the Wadkin A.C.

As Jack has said they also had the AX, and a few other A's so I think at first they thought they had a group they would call the A's. They obviously tinkered with the idea of the Cross cutting machine for a bit and thought, lets see if we can get some more depth of cut and while we are at it, some people have said they just want to cut things at 90 and don't even want depth of cut adjustment, so now they had the CA (plain straight cross cutting) and the CC (for mitre cuts, angle sawing, trenching and grooving.....etc).

Now what about that A.Y. I was talking about? Well it came for either flat belt drive or with a self contained motor, but it also came in 2 sizes the 24" and the 32". Well things must of started to get a bit confusing with all the options either with ordering or perhaps assembly or casting, because the AY soon became the AY (24") and the AK (32").

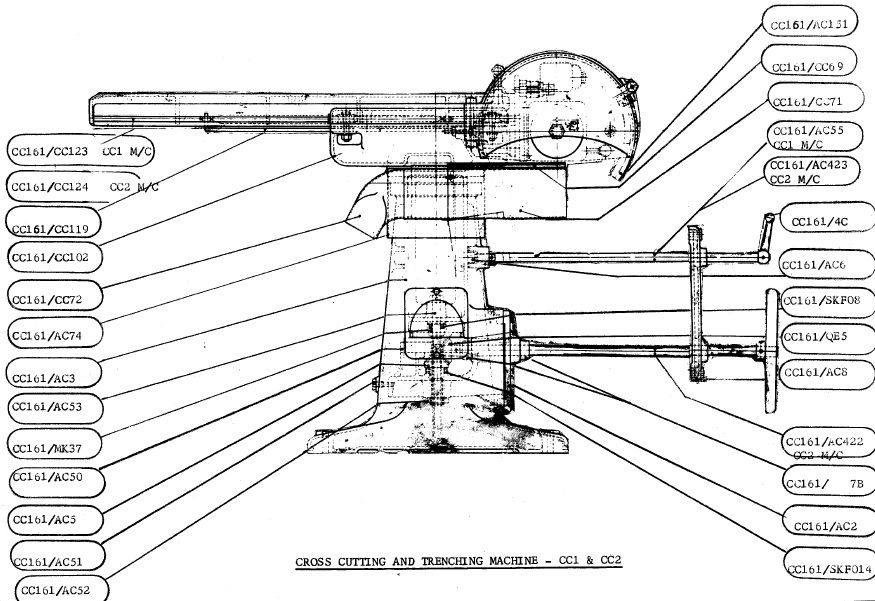

Now back to the CC, I imagine some guy in the assembly room putting together a CC, while someone in the spare parts room is looking for a spare part for and AC for a customer, and the guy in the foundry is making parts for both. If you have a look at this parts list:

You will see that some of the parts are CC some are AC and there are even others eg MK. As you can imagine, some parts are the same on one machine as they are on another, and some machines were made before the other, so when it comes to making a CC, and probably when it comes to looking at the casting on a CC, there will probably be parts marked with an earlier model part number (like Jacks example of the PK fence having PJ part numbers), and even part numbers associated with other machines (like the MK), otherwise you start having doubling up on everything (although looking at a later model machine you may find this is no longer the need to keep say an AC part, and I am guessing they may when recasting a batch change it to a CC, although that is purely speculation).

Now regarding the "A" for the RTA, well I see what you are saying about the CCA, as the CC was available in either Alternating Current or Direct Current, so what is the difference between the CC being just tagged CC and the RT being tagged RTA.

Well the PK is the same, in the fact that it was never designed to be flat belt drive, and there are certainly PK's in the wild stamped PKA, so in theory there may well be CC's stamped CCA, but when the 3 digit ##A is used in the catalogues I have seen, they are always described like this:

"A" denotes Alternating Current version and "D" denotes Direct Current version, so I think it is probably a fairly safe bet to say that an RTA is simply an RT with Alternating Current motor and the only reason we see all these RTA's and not any CCA's is simply because the RT was being produced in a time when Wadkin was adding the letter A to their alternating current machines.

Looking at Matty's catalogue cuts, I think they are actually different generations of RT's shown, and are both AC versions, just the first does not have a magnetic switch and just runs directly off the Drum switch (magnetic switch added in later version).

Hope that helps clarify some things, but as always things are never 100% clear when talking Wadkin and it's models.

Cheers,

Camo

-

14th April 2016, 03:44 AM #54

-

14th April 2016, 07:41 AM #55

Waddy yah talking about?

Waddy yah talking about?

C'mon man, I read the definition of a Waddy - I have to have two of the same Wadkins. I've only got two Wadkins, total (and bits of two more). Camo's got two BZLs, Auscab (Rob) has two PKAs*, I don't know what Matty has (does two Wadkin catalogues count?

).

).

But, yes I admit to having Wadkinitus - and I'd have more than two if I had the space (and a bit more tolerance from SWMBO).

* actually - reading a thread on another forum, I read that Rob has thirty machines, so I bet there's more than one double-up of Wadkin in that lot .

.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

14th April 2016, 11:23 AM #56

honorary Waddy Vann. Any one that documents PK changes is a shoe in.

All tools can be used as hammers

-

15th April 2016, 02:42 PM #57

If you think documenting PK changes is bad, you wait until you see my next evil undertaking (it might get me to Chief Waddie status). I'm considering a list of Wadkins by test number (not just confined to PKs, but anything and everything I can find). Just gotta decide whether there are enough Waddies here - or if I have to go to the Canadian site (heaven help me after the software upgrade there).

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

15th April 2016, 03:10 PM #58

I had to take the cat to the vet before work yesterday (he got beaten up by a neighbourhood cat) so didn't get any shed time. But this morning I got everything wired up. It now runs the right way and all the switches work as they should.

I just need to tighten everything and put the lid on the electrical box.

I had to make an executive decision with regard to the cloth covered wires. I think I've loaned out my heat gun (haven't stumbled upon it yet) and the cloth insulation is in very good condition. I don't want this job to drag out as I still have a Preston bandsaw and Wadkin PK saw in bits. In a year or two I'll probably repaint the lathe and I'll do the wiring then.

I also checked out the handle on the speed selecting drum switch - which felt very sloppy. It turns out the handle should engage in a hole in the switch shaft - but the end of the handle is missing so it barely engages. I'll need to have that repaired.

I'm going to order an MT2 spur centre, as there wasn't one with the lathe. I'm assuming this one will do the job

TTMT2.jpg

Teknatool Nova Spur centre | Trade Me (I guess I should really ask in the turning sub-forum as I think I've crossed the line from Antique & Vintage Machinery to Woodturning)

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

15th April 2016, 04:30 PM #59

Narr, keep it here Vann its your post !

Narr, keep it here Vann its your post ! Originally Posted by Vann

Originally Posted by Vann

What do u need to know ?

Do u have a live center for your tail stock ??

Melbourne Matty.

-

15th April 2016, 06:31 PM #60

Hi Matty. The lathe came with two faceplates (screw onto the 1 3/8" headstock spindle); a screw centre (also screws onto the 1 3/8" headstock spindle). These are all genuine Wadkin parts AFAIKT. Then there's a live centre stuck in the MT2 tailstock.

So I need a spur centre to fit the MT2 taper in the headstock spindle. I assume any commercial MT2 spur centre (such as the one pictured above) will do?

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

Similar Threads

-

Wadkin RS lathes, an out of the box question.

By camoz in forum WOODTURNING - GENERALReplies: 28Last Post: 10th May 2018, 03:04 PM -

Wadkin PK - Can I fit a Single Phase Motor to a wadkin pk table saw?

By Pommy Ker in forum ANTIQUE AND VINTAGE MACHINERYReplies: 17Last Post: 30th December 2015, 06:31 PM -

Wadkin PK manual link and other wadkin manuals

By Pommy Ker in forum ANTIQUE AND VINTAGE MACHINERYReplies: 0Last Post: 29th December 2015, 07:56 PM -

Wood v. machine lathes

By Dengue in forum WOODTURNING - GENERALReplies: 6Last Post: 6th December 2011, 11:15 AM -

wood lathes

By pedro in forum WOODTURNING - GENERALReplies: 27Last Post: 20th May 2003, 11:14 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

).

).

Reply With Quote

Reply With Quote .

.