Needs Pictures: 0

Needs Pictures: 0

Results 16 to 30 of 112

Thread: Wadkin Wood Lathes

-

5th April 2016, 01:14 AM #16

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Vann,

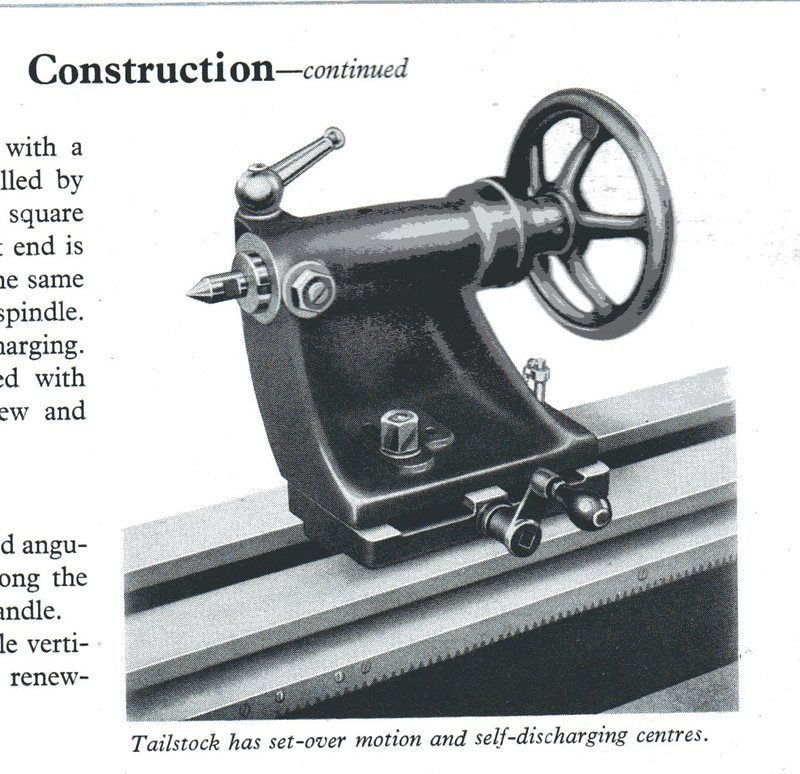

I don't think this is a packer, this is for tapering. The RS6 I have has this setup, but with a square shaft to take a handle to adjust the offset. If you look closely you can see a pin below the hand wheel, this is the locating pin for the home position.

Cheers,

Camo

-

5th April 2016 01:14 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

6th April 2016, 07:24 PM #17

-

7th April 2016, 01:52 PM #18

Well, not to be outdone, I bought an RS wood lathe machine tag. RS 133, test 3197

.

.

aRS133.jpg

Just the tag unfortunately

. Actually I bought it last year - I'm not really sure why?

. Actually I bought it last year - I'm not really sure why?

Cheers, Vann .

Gatherer of rusty

.

Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

7th April 2016, 02:40 PM #19

-

9th April 2016, 05:53 PM #20

Well... technically... it's not the start

. My first Wadkin tag is the one on my Wadkin PK dimension saw. The second tag is off the munted BCK radial arm saw I bought for parts. This is my third Wadkin tag. And my forth is on my RTA wood lathe which arrived home yesterday.

. My first Wadkin tag is the one on my Wadkin PK dimension saw. The second tag is off the munted BCK radial arm saw I bought for parts. This is my third Wadkin tag. And my forth is on my RTA wood lathe which arrived home yesterday.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

9th April 2016, 06:27 PM #21

Pick-up and Delivery

Pick-up and Delivery

I left home at 11.30pm Thursday evening and drove through the night until, after 5 hours, I had to stop at the roadside for a sleep. Another two hours yesterday morning had me at Te Awamutu College to pick up the woodlathe. 487km according to the trip-meter.

It was still exactly where the sellers photographs were taken.

aa1.jpg In the woodwork room.

I removed the tailstock. and the tool rest holder. Then unbolted the headstock - it took a bit of persuading to get it to seperate. I was just able to lift the headstock (complete with intergral motor and switchgear) to the ground - luckily the body of this unit is aluminium. Then I unbolted the legs and lowered the bed to the floor, first one end, then the other.

I was able to lift each component, except the bed, which was rolled down two 4x2s, on pipes, into the van.

aa2.jpg Half-way through loading into the van.

The woodwork instructor told me they sold their two Wadkin lathes (even though they were working fine), for modern lathes – because they wanted to standardise the tooling !! Lucky for me! And they didn’t care what price they got for them as the revenue wasn’t coming back to the technical department – hence the $100 starting price and $250 buy now on both lathes.

Once everything was loaded he was kind enough to give me a turning lesson (after I told him I had virtually no experience with woodlathes).

aa3.jpg The 3 lathes they now use (and my piece between centres)

Then it was drive back to Wellington. 7 hours driving; 8 hours all up (including breaks), and straight to bed.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

9th April 2016, 08:30 PM #22

Well done Vann !!

I see it all fitted in your van very neatly.

Did he throw in any turning chisles or are you on the hunt for some now ?

Melbourne Matty.

-

9th April 2016, 08:42 PM #23

I have three turning chisels of unknown parentage. I'll be keeping an eye out for some more.

I don't intend to get into bowl making (at present). I want to make some simple handles for tools, and some patterns for missing parts - and there's a banister required in the house (though I'm not sure if we want turned posts for that), so my range of turning chisels may not need to be extensive. However my daughter wants to try making wooden eggcups.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

9th April 2016, 09:47 PM #24

Reassembly

Reassembly

This morning I unloaded the van (and returned it to it's owner).

aa4.jpg

I cleaned off any paint or crud from machined surfaces and oiled them before bolting parts together.

aa5.jpg Re-attaching the legs (I've misplaced one bolt ).

).

aa7.jpg Turned back up the right way.

aa6.jpg Underside of the headstock.

aa8.jpg Motor tag - no specific maker mentioned - looks like the motor is made by Wadkin !

aa9.jpg Nearly all back together again.

It just needs the power cord to be attached. There was no electrical connection box on the rear of the headstock - just conduit wires inside a green hose, attached to the machine by a PVC ebow. I'll have to see if a can get some better fittings, but hope to have it running tomorrow - even with a temporary connection if necessary.

aa10.jpg I believe it should have a fitting like this...

aa11.jpg ...but all I have is this.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

10th April 2016, 06:33 PM #25

It runs - kinda...

It runs - kinda...

I wired the lathe up with a temporary connection, and with much trepidation, switched the 'On' button.

Nothing.

Okay, move the speed lever from 'Off', to 'Low Speed', and try the 'On' button again. Success well, kinda. It runs backwards

well, kinda. It runs backwards  . It's a good thing I didn't have a face plate on, as it was the screw plate half unwound on start-up.

. It's a good thing I didn't have a face plate on, as it was the screw plate half unwound on start-up.

Hit the 'Off' button. Nothing . Try again. Nothing

. Try again. Nothing  . Switch it off at the wall.

. Switch it off at the wall.

Turn it back on again. Nothing. Push the 'On' button. Starts. So at least the contactor drops out when the power is off - that's good. Hit the 'Off' button again. Nothing (sigh). Switch it off at the wall.

I know that all I have to do to get it to run the right way, is to change two wires. I'll change the Red and Blue wires so that it 's still wired Red - Yellow - Blue, just in the opposite direction. But while I have the switch out I'll need to check out the 'Off' function - and I just didn't have time for that today.

All in all, a satisfying result - even though it still needs some work.

And I think the grease nipples on the headstock might benefit from a squeeze of grease (I'd better finish off cleaning up the grease gun I bought on Trademe several months ago).

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

11th April 2016, 02:28 AM #26

I,v offten wondered if the American Oliver 159 wasn't a knock off of this lathe . There's enough similarities to constitute similar design . And all of my research of Wadkin machines I have never come across a line belt lathe even though most English manufacturers made them .

I would just like to add a little conjecture about the third letter designation. It's my understanding that the third letter only belongs to Motor driven machines and not Linebelt machines . Very few classic machines existed in Wadkin's lineup that were strictly motor drive developed. The CC,RT ,RS,PK, I would include the LQ but I believe that was a line belt machine originally as was the pattern Miller. But the pin router development could be spurred by the phase shifter's . Because the motor was being developed by Wadkin and BTH the designation I believe regards that . It's been unclear whether the PJ had an AC motor or DC and certainly some if not all of John McDougall's early examples were DC motor driven . It's also fun to see the parts mixing like brake in the square shape motor development of the Wadkin /BTH Direct drive motor that clearly dominated the range . Enjoying the thread Vann

-

11th April 2016, 07:57 AM #27

I'm now doubting my conclusion that an RTA is just an AC powered RT. Apart from the tailstock and toolpost holder, which bear pattern numbers starting with "RS" (they're common with the 6" RS lathe) all the other pattern numbers start with "RTA" (not "RT") - where as my PKA (AC powered PK) has pattern numbers starting with "PK" (not "PKA"). According to Matty's cattledog cuts there was a DC powered RT/RTA.

I'm now doubting my conclusion that an RTA is just an AC powered RT. Apart from the tailstock and toolpost holder, which bear pattern numbers starting with "RS" (they're common with the 6" RS lathe) all the other pattern numbers start with "RTA" (not "RT") - where as my PKA (AC powered PK) has pattern numbers starting with "PK" (not "PKA"). According to Matty's cattledog cuts there was a DC powered RT/RTA. Originally Posted by jgforsberg

Originally Posted by jgforsberg

So now I'm confused. This doesn't dispute what you wrote Mr Forsberg, I'm just trying to make sense of the third letter use, and work out the difference (if any) between an RT and an RTA.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

11th April 2016, 09:57 AM #28

It appears the RT is older than the RS but the letters don't suggest that . The first letter is the family of machines the second letter is the generation or model designation in alphabetical order of development in that family . At least from the drawing room perspective of development . planers were originally in the K family and later became the R Family Sometime in the early 40s . In the beginning it appears that multiple models were being developed simultaneously and it's my asertation that castings would've been development Based on the winning development In the engineering works . It's clear that model number castings appear on the majority of family designated machines and this was a common practice in Wadkin development Of a particular range . All RTA on the casting tell me is that the A C drive model RT was the first to make it out of the pattern shop and therefore became the initial castings . You Really have to look at the subtle changes like the bed casting letters or in the case of the PK the fences I've seen both PK and PJ With the PJ appearing first .

-

11th April 2016, 02:54 PM #29

Pattern Numbers

Pattern Numbers

That sounds to be a plausible explanation.

Just out of interest, here are pikkies of the pattern numbers in various places on the lathe:

aRTA11.jpg 'RTA 38' on the rotary switch panel, and 'RTA 2x' on the selector handle.

aRTA12.jpg 'RTA 42' upside down on the inboard motor mounting plate.

aRTA13.jpg 'RTA 34' inside the electrical box of the main headstock casting.

aRTA14.jpg 'RTA 37' inside the electrical box lid.

All the above castings (with the probable exception of the selector handle) are unique to the AC version of the RT woodlathe. However 'RTA' also features on the leg castings

aRTA16.jpg 'RTA 43' inside each leg casting.

And to prove myself wrong, the tailstock is NOT an RS casting, but an RTA casting

aRTA19.jpg 'RTA 36' on the back of the tailstock.

These last two support your theory IMHO.

I'd guessed that the RTA was a much newer than the RS (mostly due to the direct drive instead of belts), however finding RTA 148 (see post ♯15) with a test number so low as to be late 1920s or early 1930s suggests it is an old design. When did the RS come out?

Cheers, Vann.Last edited by Vann; 11th April 2016 at 02:57 PM. Reason: tidying up typos

Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

11th April 2016, 09:55 PM #30

Similar Threads

-

Wadkin RS lathes, an out of the box question.

By camoz in forum WOODTURNING - GENERALReplies: 28Last Post: 10th May 2018, 03:04 PM -

Wadkin PK - Can I fit a Single Phase Motor to a wadkin pk table saw?

By Pommy Ker in forum ANTIQUE AND VINTAGE MACHINERYReplies: 17Last Post: 30th December 2015, 06:31 PM -

Wadkin PK manual link and other wadkin manuals

By Pommy Ker in forum ANTIQUE AND VINTAGE MACHINERYReplies: 0Last Post: 29th December 2015, 07:56 PM -

Wood v. machine lathes

By Dengue in forum WOODTURNING - GENERALReplies: 6Last Post: 6th December 2011, 11:15 AM -

wood lathes

By pedro in forum WOODTURNING - GENERALReplies: 27Last Post: 20th May 2003, 11:14 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote

.

.