Needs Pictures: 0

Needs Pictures: 0

Results 91 to 105 of 112

Thread: Wadkin Wood Lathes

-

14th May 2016, 03:55 AM #91

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2012

- Location

- uk

- Posts

- 456

-

14th May 2016 03:55 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th May 2016, 08:23 AM #92

Gatherer of rusty

Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

14th May 2016, 09:49 PM #93

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2012

- Location

- uk

- Posts

- 456

Here you go Vann, I did notice some subtle differences between the two lathes. One thing for definite is make sure you have the correct tail stock when you have two machines and your restoring one. I finished everything and when I came to put it all together the tail stock wouldn't fit in between the bed gap. The size difference is very small but if a wadkin part doesn't fit just doesn't. I then had to dig out the other part and make it pretty. Strange they both date from 1951, could that be change over year for tin to cast tags

-

17th May 2016, 08:22 AM #94

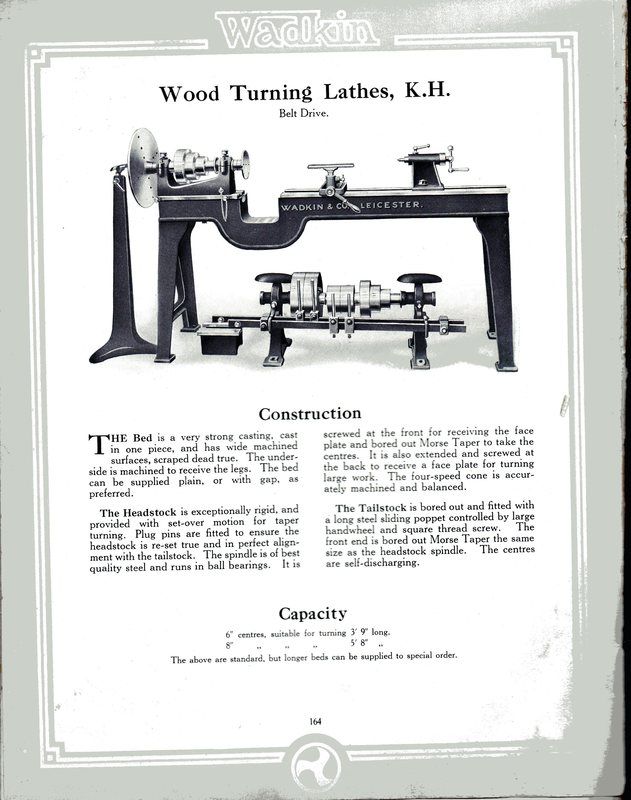

It's a KH Jim, but not as we know it!

It's a KH Jim, but not as we know it!

Way back in post ♯30 (page 2 of this thread), Matty posted this picture of a Wadkin KH woodlathe.

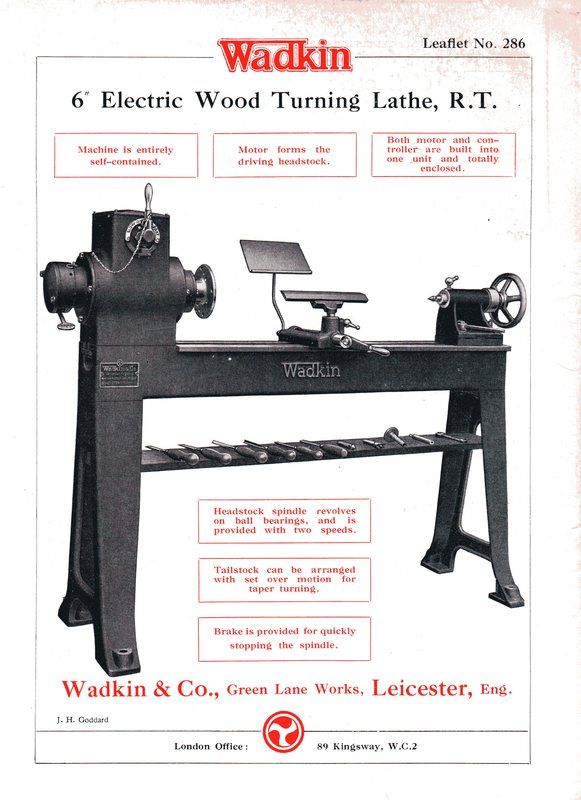

While in post ♯80 (page 6) I posted this picture of an RT at Cowbridge Sawmill museum in UK.

RTcowbridge.jpg

This morning the fine folks at Cowbridge sent me these photos.

aKH1.jpg aKH2.jpg

Turns out it isn't an RT after all, but a KH - without the gap bed.

aKH3.jpg KH 253, test 6759 - making it pre-1937

Of further interest is that it's test number 6759, is later than that of the RT shown in post ♯50 (p4) of RTA 148 - test 5629 - meaning both RT and KH were in production at the same time - albeit both sharing the RT bed (most unseemly behaviour for the 1930s ).

).

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

7th July 2016, 06:35 PM #95

Tailstock Nut

Tailstock Nut

Well, after some careful research (I asked Camo and wallace about the size of their nuts - they both have two BTW

) I have concluded that the correct size of the tailstock nut is 1.10" (27.94mm) across flats.

) I have concluded that the correct size of the tailstock nut is 1.10" (27.94mm) across flats.

Interesting - because 1.10” is the old, pre-WW2 standard for 5/8” BSW nuts and bolts, while 1.01” is the revised standard from WW2 on. I did wonder if Wadkin retained the larger nut for the larger flats, or if they simply had a large stock of the special nuts from before the war. However, while wallace has a 1940 lathe with that size nut (which could well be pre-WW2 stock), Camo's RS lathes date to 1953 and later - so almost certainly they retained that size for the larger flats. The nut on Henry's is also this size, but I don't know the age of his lathe.

Camo put the length (height?) at 1.014"

I asked my machinist mate to make a couple of nuts. I had a length of rusty 1 5/16" diameter bar (the column of an old Boynton & Plummer post drill) and he machined them from that. And here they are...

RTAnut1.jpg New nut fitted - old nut at left, spare nut at right.

RTAnut2.jpg The washer is off a CK saw - a genuine Wadkin part but thicker than normal in this application.

Cost me $50 for the two. The nut was tight after an initial few turns. I suspect the bolt threads may be a bit stretched, thanks to years of abuse in the school classroom.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

19th August 2016, 09:25 AM #96

So that spanner was to fit the standard post-WW2 nut (1.01" across flats) that came with the lathe.

Once I'd had a replica nut made up - to ye olde pre-WW2 standard (1.1" across flats) - I had to find another spanner. I found this ¾"w + ⅝"w one and once again painted it in Wadkin grey.

58spanner1.jpg

However I found that having the bigger ¾" BSW jaws hanging off the other end made the spanner a bit awkward in use. I hunted through some old spanners and found a ⅝"w + ½"w spanner, but the half inch jaws had been abused and were no longer parallel. So I ground off the jaws, and ground and filed the end until I had this...

58spanner2.jpg

Much easier to use, and painted matt black (not Wadkin grey) as black appears to be the colour of spanners supplied by Wadkin.

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

11th September 2016, 07:19 AM #97

This is one of the Wadkins I used from 1959 till 1970. The others were RS 10 lathes. I have Wadkinitise, I think they call it. Loved using these.

image.jpg

-

11th September 2016, 08:38 PM #98

-

12th September 2016, 09:42 PM #99

Yes it's the Ru. I worked in a steelworks patter shop. We turned work nearly 8' diameter & nearly 12' long spindle work. The bed was 10' long & could be wound away from the pedestal with a rack & pinion.

this is one of the pieces we turned on that lathe. It's a liner for a steel making vessel. It is approx8' diameter x 16' tall. It was made in segments forming sections 2' deep & bolted together to form the whole. We were experimenting liquid oxygen steel making & used an old Bessemer converter for the trials this former was erected inside the vessel so the refractory lining could be rammed in place, then removed in sections. Ah, memories.

image.jpg

-

13th September 2016, 02:18 AM #100

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2012

- Location

- uk

- Posts

- 456

Love the old pictures, did you put that first one on a different forum a few years ago? It rings a bell. I very nearly bought an RU last year for £1500, I've kicked myself ever since. Any more old pics?

-

13th September 2016, 09:21 AM #101

-

13th September 2016, 06:13 PM #102

Only when you moved the bed out to maximum length.

I used one of these a few times as an apprentice at the local naval dockyard.

Didnt use it for the capacity, the RS6 was being used by the other apprentice.

The foreman was silly enough to give us a globe valve pattern each, so of course we were flat out.

H Jimcracks for the rich and/or wealthy. (aka GKB '88)

Jimcracks for the rich and/or wealthy. (aka GKB '88)

-

24th September 2017, 07:36 PM #103

Back on page 1 (12th post) Matty kindly put up 4 catalogue cuts. Unfortunately they've been photobucketted

. I thought I'd copied all four, but here's the only one I can find:

. I thought I'd copied all four, but here's the only one I can find:

RT cat2.jpg

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

25th September 2017, 08:30 AM #104

RS Banjos

RS Banjos

I had no intention of carrying out any work on my lathe at this time, however you may recall the broken banjo handle...

The Wadkin RT uses the same banjo as the Wadkin RS (the castings have RS parts numbers cast into them). It seems that broken banjo handles aren't uncommon:

Rest1.jpg Sellers photo of my RTA with repaired handle.

Rest2.jpg Sellers photo of RTA 339 (same school) also with repaired handle.

Rest3.jpg An RS banjo with the same aliment.

It had been my intention to have a new handgrip portion turned up, then cut the broken portion at the collar, drill and tap both pieces - and then probably braze the two parts as well.

Imagine my delight when I spotted a Wadkin banjo in a $20 auction of old woodlathe parts.

Rest4.jpg

Cost me $72.60 by the time bidding was over . There was a toolrest there as well, so still a good price.

. There was a toolrest there as well, so still a good price.

I was further delighted when the seller said he had another toolrest that he would throw in...

Rest5.jpg What , another banjo!

, another banjo!

So now I have three.

Rest6.jpg My original at left.

I'm one happy chappie

Cheers, Vann.Gatherer of rustyplanestools...

Proud member of the Wadkin Blockhead Club .

.

-

25th September 2017, 03:47 PM #105

Nice one Vann !!

Did that lot have to be posted or was it within reach by car for you ?

I just did a BRA Bursgreen handle repair sort of similar. Ill have to put a picture in a new thread.

It was all done with a welder and angle grinder and its surprising how good you can get it if you take your time .

I would have done that handle the same way.

Rob

Similar Threads

-

Wadkin RS lathes, an out of the box question.

By camoz in forum WOODTURNING - GENERALReplies: 28Last Post: 10th May 2018, 03:04 PM -

Wadkin PK - Can I fit a Single Phase Motor to a wadkin pk table saw?

By Pommy Ker in forum ANTIQUE AND VINTAGE MACHINERYReplies: 17Last Post: 30th December 2015, 06:31 PM -

Wadkin PK manual link and other wadkin manuals

By Pommy Ker in forum ANTIQUE AND VINTAGE MACHINERYReplies: 0Last Post: 29th December 2015, 07:56 PM -

Wood v. machine lathes

By Dengue in forum WOODTURNING - GENERALReplies: 6Last Post: 6th December 2011, 11:15 AM -

wood lathes

By pedro in forum WOODTURNING - GENERALReplies: 27Last Post: 20th May 2003, 11:14 AM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote

.

.