Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 15

Thread: Wolfenden 12" Jointer

-

17th August 2015, 01:37 PM #1

Wolfenden 12" Jointer

Wolfenden 12" Jointer

Does anyone have a Wolfenden 12" Jointer? I'm picking one up in a week or so (machines 4u $750 http://www.machines4u.com.au/view/?advert_id=243749?).

Looks like it will need a bit of cleaning up and I'll look at adding a spiral cutter at some point - just moving it around is going to be interesting, I expect it will be a fair lump of a thing and once in place I doubt if it will be shifting too soon

But for the moment, if anyone has any info about these machines, I'd appreciate hearing about it - usual web searches have found very little... that just makes me more curious I think, therefore I am... unable to get anything finished!

I think, therefore I am... unable to get anything finished!

-

17th August 2015 01:37 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

22nd August 2015, 12:54 PM #2

Hi Moo,

Firstly well done on your purchase, when I was there looking at other equipment I did have a brief look at your machine and also met Jim, who is a gentleman I might add.

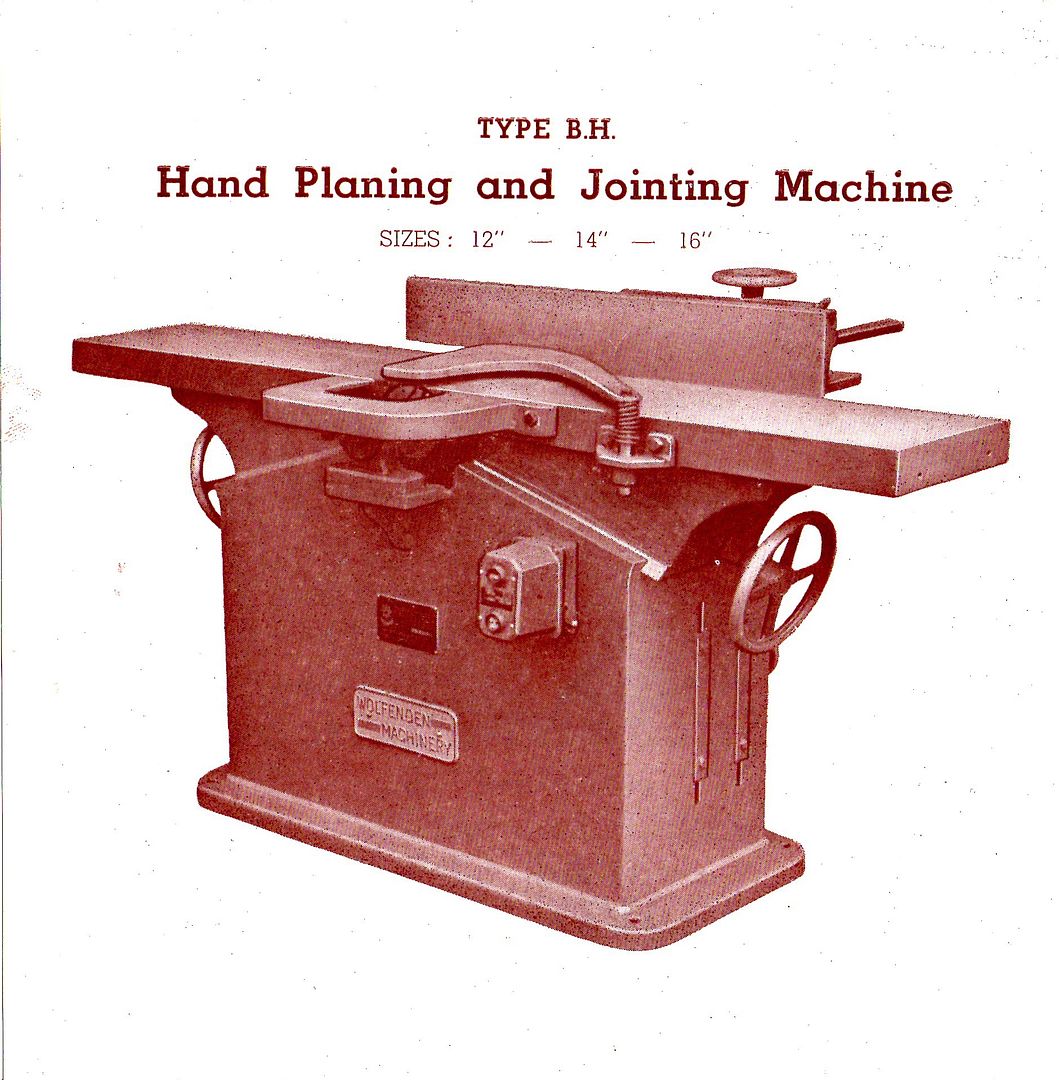

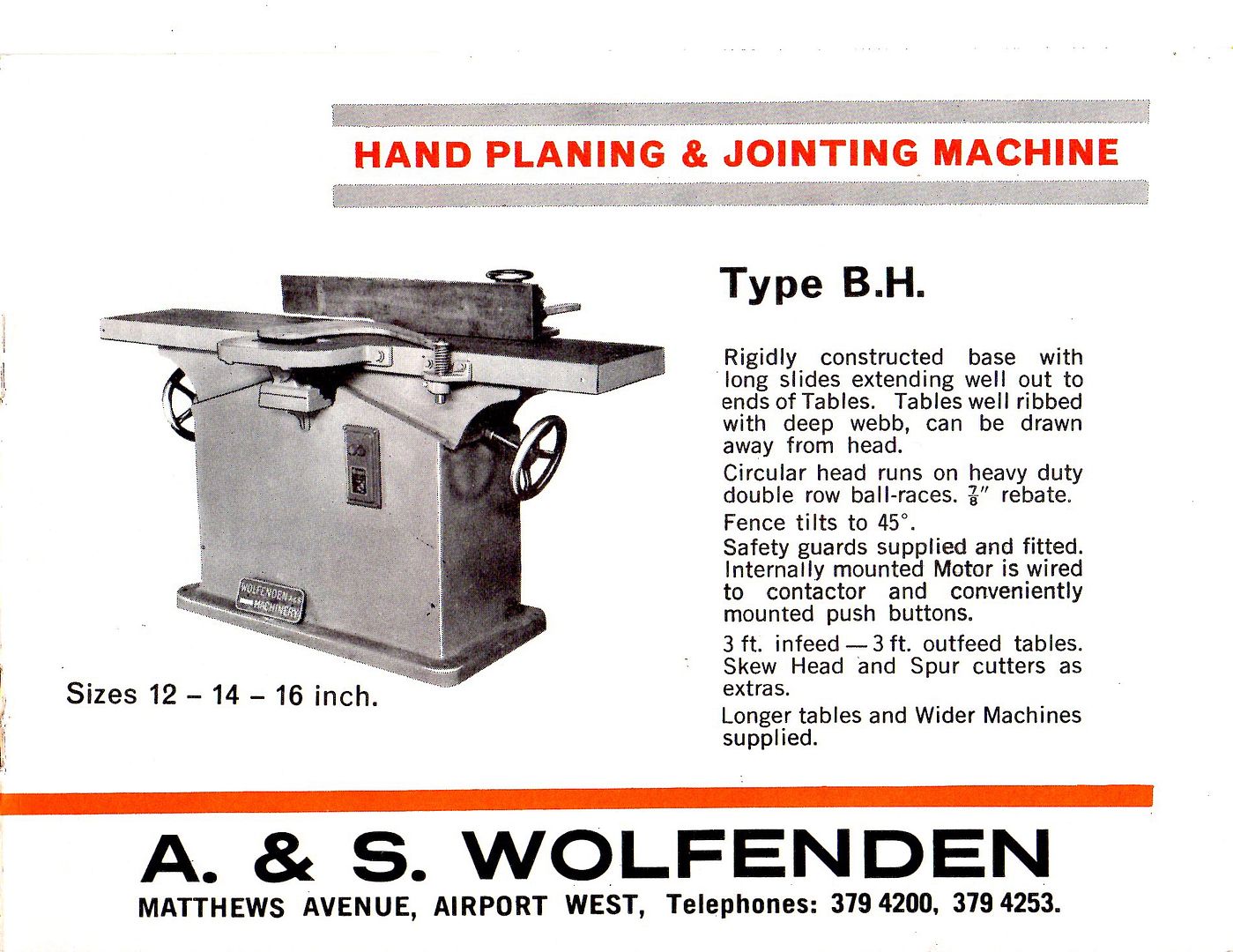

I'm Pretty sure your Jointer is a 1957 model, Wolfenden made this style of jointer from roughly 1954-55 to well into the 70's

Not forgetting that the Wolfenden Brothers split in 1947, resulting in two machinery manufactures.

“Buzawolf” who were Charles Wolfenden & Co and Wolfenden Machinery PTY. LTD. who were Allen and Stanley Wolfenden and later named A & S Wolfenden and located at Matthews Avenue Airport West around 1965.

Your machine was produced by A & S Wolfenden also.

You mentioned putting in a spiral head into that machine, I was impressed with the plethora of cutter blades that that machine came with there would of been at least 15 sets.

One of my good mates has the same model as well and I have had some time to look over it carefully, what caught my attention first up was the diameter of the cutter-head, it is huge !!.

Its a 2 blade head with dovetailed gib-ways and is quite safe to use once set up.

Good luck with the pick up, I hope the weather is kind on your trip down.

Melbourne Matty.

-

22nd August 2015, 03:30 PM #3

Thank you for that Melb Matty - I'm still tossing up what I'll need to move/transport her. How heavy do you think she'd likely weigh?

Cheers

LeanneI think, therefore I am... unable to get anything finished!

-

22nd August 2015, 08:45 PM #4

Hi Leanne,

Matty sent a text asking for pics of my machine....

here are some pictures of the machine Matty was talking about.

Mine came from a school in Ferntree Gully. I'd bought a lathe, and the bloke asked if I wanted the buzzer.

I fitted a 3hp single phase motor on a plate which is bolted into the original adjuster slots. All up that conversion cost about $450.00.

I'm not that good at weight estimates, but I think 3 - 400Kg max is about where it is.

A friend here puts his machines on wooden plate, and that makes them a bit easier to shift around the workshop, but if the extra few inches extra height is not on for you, choose a place for it and leave it there.

The head on mine is 130mm, huge compared to some I've seen.

I love the machine ... I was lucky in that it was still in good nick, and the tables are co-planar.

If you have any specific questions, I'll try and help out.

Cheers,

Peter

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

23rd August 2015, 11:08 AM #5

I was able to move my 12" jointer which I think weighed in at 600kg (1300lbs) With a box trailer and engine crane. This was done by three blokes one end and off loaded by two the other.

…..Live a Quiet Life & Work with your Hands

…..Live a Quiet Life & Work with your Hands

-

23rd August 2015, 12:12 PM #6

Hi Leanne,

I've had those all cast iron buzzers, like the one in the trailer above.

As you probably already know, the ones we have are fabricated steel, and although quite heavy, aren't as heavy as the thick walled cast items.

I based by estimate on that.

Either way, if it is 600 or 400 kg you will need pretty much the same eqipement.

Are you moving it professionally?

crane truck etc.

you're moving it interstate aren't you?

Are you planning on doing it like those blokes in the pics above?

Moving around the workshop floor is another thing altogether.

are you on concrete or timber?

Cheers,

Peter<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

23rd August 2015, 01:41 PM #7

Thanks guys, that's all really useful.

Have a couple of options that pick up, either way will need a few hands maneuvering

Just depends who I can rope in to come with me on the pick up trip... Oh brother of mine, you free for a few days??? I think, therefore I am... unable to get anything finished!

I think, therefore I am... unable to get anything finished!

-

23rd August 2015, 02:16 PM #8

A road trip!!

excelent fun.

Weve done a few of those. You get to know someone's taste in music very quick.

Hehehe

plenty of time to solve all, or most of the worlds problems.

Good luck.

Peter<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

11th September 2015, 09:38 PM #9

Well, pickup went well. Of course, it was always going to go well when the seller had a forklift handy

Wrapped and strapped, the drive home from Kilsyth, VIC to Wollongong, NSW was uneventful - I like uneventful!!

20150905_044706754_iOS.jpg20150905_044729445_iOS.jpg

While the shed is built, home for the jointer is a storage unit. Took 3hrs to offload using an engine crane and a whole lot of monouvering to get around 600kgs to move on teeny weeny steel wheels across blue metal exposed concrete on an incline to enter the storage unit. Picture human hitched like bullock moving inch at a time... yep, something like that.

20150906_041452578_iOS.jpg20150906_042201199_iOS.jpg

Will be a few months before I get to play. And there maybe a project to build a mobile gantry at some point soon I think, therefore I am... unable to get anything finished!

I think, therefore I am... unable to get anything finished!

-

12th September 2015, 11:40 AM #10

-

5th December 2016, 10:43 PM #11

Moving from storage to the shed was covered quite a few months ago in the shed build thread here, but today I was able to switch her on for the first time, finally.

There's a bit of cleaning up that needs to happen before I can put her to good use. That, and sort out a blade guard, seeing as hers is AWOL.

Peter, (or anyone really) do you have any pics/specs of the one on yours?I think, therefore I am... unable to get anything finished!

-

7th December 2016, 10:04 PM #12

-

8th December 2016, 02:54 PM #13

Hi Leanne,

Mine is made from 20mm ply.

Here are some pictures

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

8th December 2016, 06:42 PM #14

Excellent, thanks Peter. That will get things moving.

Cheers

Sent from my iPhone using Tapatalk ProI think, therefore I am... unable to get anything finished!

-

14th December 2016, 05:36 PM #15

A couple of Q's Peter - apologies for the drawing quality, hopefully it makes sense: jointer drawing 20161214.jpg

It appears that the the brass(?) bracket is attached via a bolt into the tapped end of the 1" rod - does the bolt bottom out in the tapped end leaving clearance above the rod end for the bracket and washer to swivel about the rod itself?

I'm also assuming that the upper leg of the torsion spring is held captive by the plywood against the internal 90deg angle of the bracket.

As an aside - I notice on your model there are two spacers between the bed and the rod holding bracket at the front of the machine. Mine's flush against the bed (same as in the sales brochures Matty posted above). Do you know why the spacers are there?

Cheers

LeanneI think, therefore I am... unable to get anything finished!

Similar Threads

-

Wolfenden Jointer

By woodturner777 in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 17Last Post: 26th February 2014, 08:55 PM -

Wolfenden Jointer

By woodturner777 in forum MUSICAL INSTRUMENTSReplies: 1Last Post: 24th February 2014, 07:35 PM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote