Needs Pictures: 0

Needs Pictures: 0

Results 1 to 12 of 12

Thread: Wolfenden 12" Jointer

-

19th November 2016, 11:43 AM #1

New Member

New Member

- Join Date

- Nov 2016

- Location

- Melbourne

- Posts

- 3

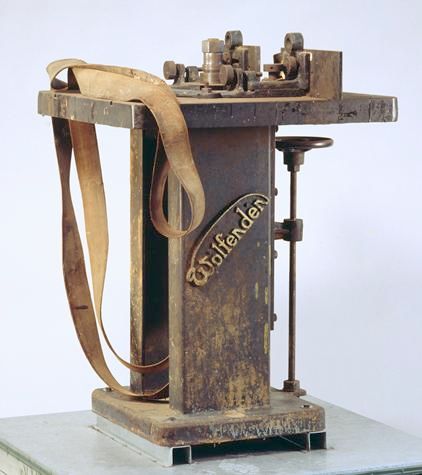

Wolfenden 12" Jointer

Wolfenden 12" Jointer

Hi

Just bought an old Wolfenden 12" jointer to restore and I have a couple of questions.

1. I want to strip the paint right back and spray it the original colour. Unfortunately I can identify at least three layers of different colour paint. Does anyone know what the original factory colour for wolfenden was? Better yet does anyone have a pantone number for it?

2. I'd really like to date the machine but can't find much info online about this particular jointer. Does anyone have any links that would help me get a reasonably accurate date of manufacture?

Thanks for your help

CatIMG_20161119_105512.jpgIMG_20161119_105527.jpgIMG_20161119_105641.jpg

-

19th November 2016 11:43 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

19th November 2016, 03:25 PM #2

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jul 2010

- Location

- melbourne

- Posts

- 382

Hi Cat,

my suggestion is, if you're taking the name plate off during the restoration, the original colour is probably beneath that.

Good looking bit of gear by the way.

Cheers

Frank

-

19th November 2016, 07:54 PM #3

Nice machine Cat,

The museum of Victoria has some Wolfenden machines in the Blue /Gray I can see under the lighter green. Pictures are on the net somewhere ? Matt will know . Looks like your third colour is the orange on the name plate . That could be original ?? the museum ones have a different name plate casting and are Yellow. It looks like the name is part of the casting though and wont come off like Frank said, sorry Frank I could be wrong though . I think when it was cast the name plate was screwed to the pattern and the casting shows the screws that held the plate on . You may get a good match from under the switch box Cat. Rather than a paint number ,which I don't think any one can supply, get a good sample, remove a part with a good bit left, and take it to Paint Spot, the business, for a match. I love that original Wolfie colour . Id be trying to remove the top coat and save the original Blue gray.

Rob

-

19th November 2016, 09:55 PM #4

Nice get! Love Wolfenden machines, unfortunately they're all a little too big for any shop I'm likely to occupy.

-

20th November 2016, 08:27 AM #5

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Nov 2011

- Location

- Newcastle NSW

- Posts

- 775

Hi Cat,

That is a nice machine, thanks for sharing some photo's.

For he purpose of determining the age of the machine, the company started in 1918, but they didn't start manufacturing woodwork machinery until 1921 when they moved to Hopkins st Footscray. Looking at the badge on your machine (part of the casting), suggests it is an early machine, but it's going to be hard narrowing things down further than that.

If I had to guess colour, I would say the colour on the fence (as seen in your 3rd photo), but as already suggested generally removing bolts and parts should help find the original colour (as most repaints tend to be a spray or brush without dismantling).

cheers,

camo

-

20th November 2016, 10:00 AM #6

Hi Cat,

I had the same machine for a while, and mine was painted a real bright blue.

Back when I had it, if memory is working right, we thought it was from mid 1920s through to about mid to late 1930s.

It is a great old beast, only sold it because a closed school in Ferntree gully through up a more recent one from the same company quite cheap And the gib type head was a bigger diam, and vast improvement on the older clam-shell design

Here it is in it's bright blue paint There were a few places where another colour was visible underneath.

It looks like yours has the blue/grey like mine, and over it the green/grey of later Wolfenden machines, like my later buzzer.

That blue/grey looks like the colour of my bandsaw, which was a 1980's restoration done by Wolfenden.

That blue/grey would be my choice if someone made me repaint yours .... but I don't go for repainting as a principle. I like them to carry the history so I can see it. Other folk here love the full resto, up to as new ... or better. That's a ligit personal choice, and no rule is there to follow. I think getting the mechanicals safe, and right is a primary concern.

Without knowing where you are with mechanical things, and tools etc, hard not know how much you want/need, and to perhaps give too much or too little info.

Tell us more!

There are a few good people here who will follow along, and help with advice if asked. I've got a few pics of the early machine stripped down from when I replaced bearings, and fitted a pulley & 3hp single phase motor.

Cheers,

Peter

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w

<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

20th November 2016, 10:27 AM #7

New Member

New Member

- Join Date

- Nov 2016

- Location

- Melbourne

- Posts

- 3

Thanks to everyone for all the advice. I think I'll try and pull a bit of paint off the worst of the rust/peel areas and take it down to get a colour match done on the blue grey. The suggestion of removing the switch box sounds like the best idea to find some original paint. I would like to strip it back and get the "as new" look to it so I'll do a complete strip down and respray. Yes this machine is way too big for my shed, but it was just so beautiful I couldn't stop myself from buying it. (My partner thinks I'm crazy for thinking a machine is beautiful!)

I have had a look at the museum website and done article searches in papers (Argus mostly) and as camoz and lightwood have suggested it looks like it was manufactured between 1922 and the early/mid 30's. Around the 30's this model started to get integrated motor mounts which my hasn't got and also they started using screw on name plates around this time as well.

Lightwood, was the 3hp motor enough to run it? I'd like to keep it to single phase if I can.

The rebuild won't start for another few weeks as I have a full sheet cnc to complete in the next few weeks, but I would love to share pics of the strip down and rebuild if people are interested (I'll be taking lots of pictures anyway as I strip it down so I know where things come from and how they go back LOL)

Thanks everyone

Cat

-

20th November 2016, 11:50 AM #8

You've come to the right place ... beauty in old cast iron machinery is what it's all about here!

Cat,

I was doing some work for a bloke who sold motors, and the 3hp in 415v seemed to be standard for this type of machine.

I've found the 3hp is about as much as a standard elec circuit is happy with, and never had an issue with the motor power.

My machines are on 16a circuits, and my thicknesser is the same 3hp setup.

Back then, after asking around, it seems they run around 4000 - 5000 rpm at the head, so that got the rpm & pulley sizes sorted.

I needed a single phase capacitor start & run, 4 pole, 1440 rpm motor. (I think I'm better of with what I have, rather than a 2-pole 2880rpm)

So I have a head diam of 130mm, head pulley 112mm and motor pulley 320mm.

He got me a couple of WEG motors, made in Brazil.

They are a slow start, and the large - small pulley setup, to get the rpm step up, does take a while to get going.

Cheers,

Peter<!--[if gte mso 9]><xml> <w:WordDocument> <w:View>Normal</w:View> <w:Zoom>0</w:Zoom> <w oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

oNotOptimizeForBrowser/> </w:WordDocument> </xml><![endif]-->

-

20th November 2016, 12:35 PM #9

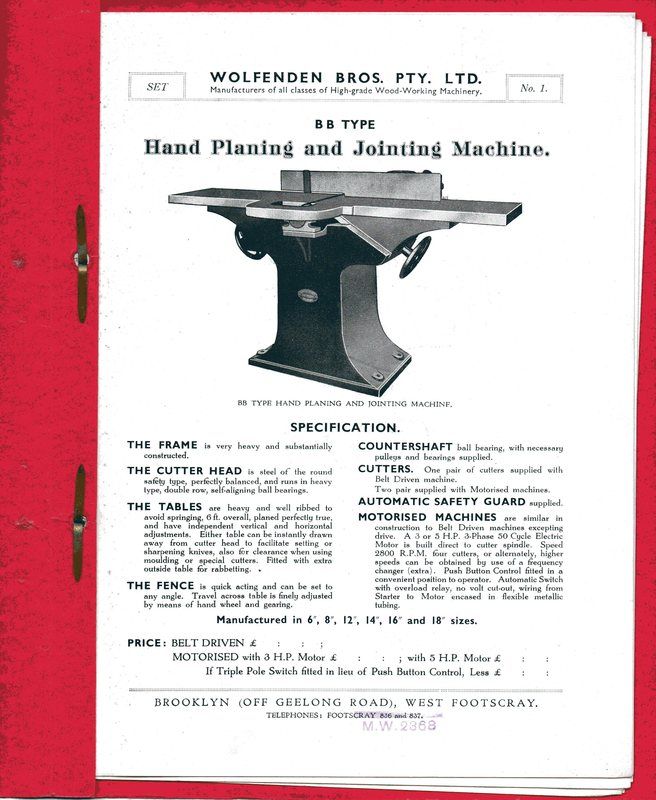

Pretty sure Rob is referring to these machines below, and although later that your machine Cat they still show a good original paint colour.

I would agree with Rob either a Blue/grey colour or satin Black would be my choice of colour but do your paint scraping and see what you find.

Here is a catalogue cut of your machine from what seems to be a Late 1920's early 1930's catalogue with no date on it so I'm just speculating.

Melbourne Matty.

-

20th November 2016, 01:07 PM #10

Yeah that's them . I went to that turners workshop before it was all pulled out . That was a long time before I knew any of you cast iron tragic's , lol . You should have seen that workshop though! I did take my camera that day but don't know what happened to any pictures?

All belt driven ,with big Owner built wood lathes made of wood . There must be pictures at the museum of the rest of the work shop , They had first pic of all the machines and benches and they took it all . They would have documented it . I'm going to ask right now . I'm still friends of the lady from the museum who was in charge that day and have just got back in touch because of facebook.

Rob

-

20th November 2016, 02:14 PM #11

GOLD MEMBER

GOLD MEMBER

- Join Date

- May 2013

- Location

- Rockhampton QLD

- Age

- 68

- Posts

- 2,346

Welcome to the forum Cat.

Ross

-

20th November 2016, 07:49 PM #12

One thing I noticed on your machine Cat, that you should check out, is why are these screws holding a plate where they are . And has the job been done well. It looks like the machine has thrown a blade, broken the back table and had a repair made . By the screw position it looks like it should be going through into the cast iron underneath . And if its all good and tight no problem. Just check it is screwed to the casting in three spots and looks good.

And read a little about checking the condition of a head like that , how the screws should look and all that. I think there are threads here on it that Matty or Jack put up.

Rob

Similar Threads

-

Wolfenden 12" Jointer

By Moo73 in forum ANTIQUE AND VINTAGE MACHINERYReplies: 14Last Post: 14th December 2016, 05:36 PM -

Wolfenden Jointer

By woodturner777 in forum ANTIQUE AND COLLECTABLE TOOLSReplies: 17Last Post: 26th February 2014, 08:55 PM -

Wolfenden Jointer

By woodturner777 in forum MUSICAL INSTRUMENTSReplies: 1Last Post: 24th February 2014, 07:35 PM

Thanks:

Thanks:  Likes:

Likes:  Picture(s) thanks:

Picture(s) thanks:

Reply With Quote

Reply With Quote