Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 43 of 43

Thread: Embroidery table and drawer

-

29th July 2011, 06:32 PM #31

Interesting design. Are you going to allow for wood movement?

-

29th July 2011 06:32 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

29th July 2011, 06:35 PM #32

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

31st July 2011, 05:47 PM #33

Made a start on the table ends and they required a 60% angle cut, I attempted to cut on the tablesaw using a spacer but doing a test run my fingers were a bit to close to the blade and I thought "I don't need that, I will cut using handsaw and finish with a hand plane".

Screwed the former to my saw board and also clamped down the cutting piece and cut with a Japanese saw.

Fitted the ends individually and the last one I redrew the angles like this.

And got a reasonable joint to complete the top, and ready to put in biscuits later.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

31st July 2011, 05:58 PM #34

Nice to see how this is coming together.

-

1st August 2011, 05:53 PM #35

I set the biscuits up (Triton way) but could not get a satisfactory fit on the fifth (end piece) board. So I glued up as per picture.

When the parts above were set I was then able to fit the final piece and it only needed a couple of strokes with the plane and bingo it went in. I will have to clean up the edges and faces.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

2nd August 2011, 05:47 PM #36

A couple of close ups of tabletop each end, this is after planing, sanding with 60 & 120 orbital sander, most probably will go to the 300's before varnishing.

Took the carcass and top indoors for a positioning and the lady seems satisfied.

Starting on the drawer fronts next.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

2nd August 2011, 11:11 PM #37

Looks good.

-

3rd August 2011, 06:32 PM #38

Before doing those drawer fronts I did a bit of tidying up, its very warm here again today and tomorrow.

So the drawer rail and base need to be smartened at the area marked with crosses.

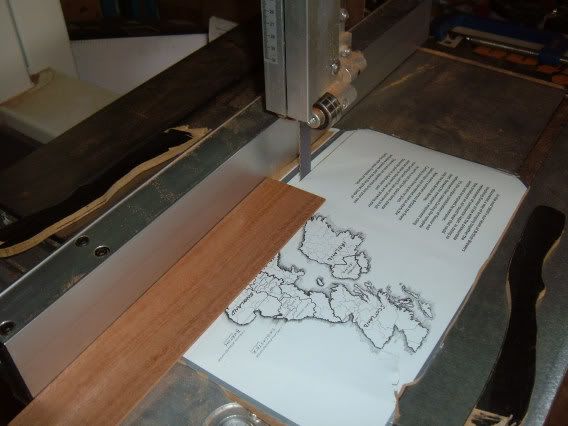

So I took a slice of around 1.5mm of a short board and then cut two thin slats on my new bandsaw but to avoid a rubbish finish I covered the table throat with a bit of heavy card and got a nice clean cut.

Then did my thing at both ends.

Perhaps today I will complete the drawers, although the forecast is hotter.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

4th August 2011, 06:06 PM #39

Just a small progress report today, (it was too warm yesterday) I put on those cover strips to the drawer assembly carcass rails and they have gone on nicely.

(see photograph previous post for part mentioned (with crosses)

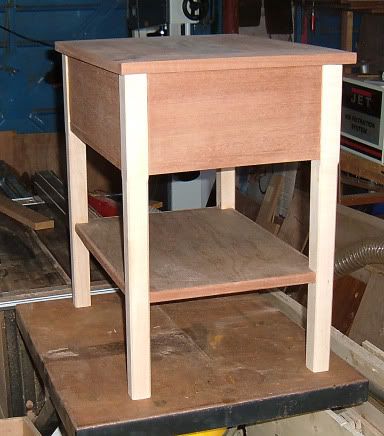

Status now reached. Drawers to be completed and top to be fitted.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

5th August 2011, 05:57 PM #40

Started on the drawer and made it mainly an evening job.

Never in the past have I wanted to do mitred corners on a bandsaw but I thought I would try it this time, and it worked.(even the mitre gauge is accurate and goes to 60%.) Made my self a high fence from an offcut of lime scrap given me some years ago and voila!

Then cut the contrast colour, maple, and I was reasonably happy cutting that small piece on the BS. I do have to use the sanding machine disk to get a good fit.

Commenced gluing the pieces to the drawer front at left hand side.

And finished off the evening putting the maple pieces in, the last small white piece needed tapping in with a hammer, nice and tight it was.

Got in mind some two colour exotic to complete the handle portion, AB are its initials, do you know what that is?woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

7th August 2011, 12:00 PM #41

No idea but will wait and see.

-

8th August 2011, 05:53 PM #42

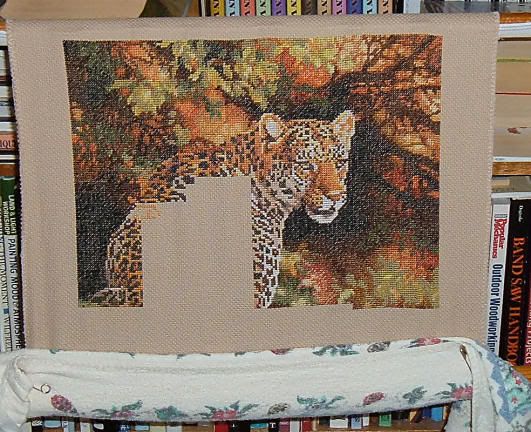

Here we come to the final stage of the embroidery table for my wife and pictured below is her latest project, a crossstitch reaching the halfway mark.

The wood chosen for the handles is African Blackwood, its black and has a colour variation to cream.

I machined on the router table to this profile.

It works with hand planes and machinery very nicely and is imo a good and cheaper substitute for ebony.

The drawer fronts were sanded down to 120 grit.

and then handles glued and screwed as per picture and displayed below.

Rear view of table

The table will most probably be fitted with casters, it is quite heavy. I intend to now bring the furniture indoors for a month before fixing the table top and then put on a finish of varnish.

I hope you have found visiting this thread interesting, it was a pleasure for me making and posting to keep up my momentum to the finish.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

8th August 2011, 10:52 PM #43

It was enjoyable to watch this work in progress. I also agreed with you that posting does help keep you moving through to the next steps.

Similar Threads

-

Hall Table Drawer

By groeneaj in forum WOODWORK - GENERALReplies: 7Last Post: 3rd November 2010, 10:29 AM -

Myrtle 4 drawer coffee table

By AlexS in forum WOODWORK - GENERALReplies: 17Last Post: 1st April 2010, 02:30 PM -

Embroidery cabinet.

By hahnice in forum WOODWORK PICSReplies: 18Last Post: 7th June 2009, 07:10 PM -

coffee table drawer

By mattym83 in forum WOODWORK - GENERALReplies: 17Last Post: 9th October 2008, 12:54 AM -

Five Drawer Embroidery cabinet a la AlexS

By jow104 in forum WOODWORK PICSReplies: 12Last Post: 1st June 2005, 09:57 AM

Reply With Quote

Reply With Quote