Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 22

Thread: scratch building

-

26th August 2005, 10:48 PM #1

scratch building

scratch building

I was going out of the back door towards the workshop and the wife said

" I could do with something better to hold those kitchen spatulas"

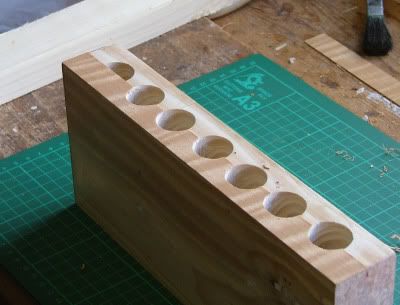

So I went to my offcut box and pulled out a length of 5x2 (straight away like a good boy),

cleaned up two sides

drilled six holes

Put the timber through the bandsaw and then chiseled out the rest of the tool holder slots:

Reassembled the 5 x 2

And reglued back together

Now I want to clean up the other 4 sides and place a triangular section at bottom to add stability.

But can member advise me how to proceed and do a veneer job on this creation. I have some sycamore, black walnut or teak available.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

26th August 2005 10:48 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

26th August 2005, 11:36 PM #2

Errmmm... I don't want to rain on your parade, but are you sure the other half would consider that "better?"

Errmmm... I don't want to rain on your parade, but are you sure the other half would consider that "better?" Originally Posted by jow104

Originally Posted by jow104

The female species have odd ways of looking at things; they don't see needing to remove one tool to get at another as a chance to play with their toys...

But I like the idea. Might have to pinch it.

- Andy Mc

-

27th August 2005, 01:46 AM #3

Well she keeps knocking the plastic tower over, so I reckon I can't lose.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

27th August 2005, 02:25 AM #4

Very thoughtful of you Jow!

....................................................................

-

27th August 2005, 06:13 PM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- Sep 2004

- Location

- Melbourne

- Age

- 87

- Posts

- 1,327

Why veneer it Jow . Why not lash out and make one out a bit of solid oak or how about making a bigger round base to stabilize the plastic tower

I've just become an optimist . Iv'e made a 25 year plan -oopps I've had a few birthdays - better make that a 20 year plan

I've just become an optimist . Iv'e made a 25 year plan -oopps I've had a few birthdays - better make that a 20 year plan

-

27th August 2005, 06:37 PM #6

The timber is construction grade softwood and vey porous and from my usual source. Secondly I have never done any veneering and want to get some action.

The timber is construction grade softwood and vey porous and from my usual source. Secondly I have never done any veneering and want to get some action. Originally Posted by Peter36

Originally Posted by Peter36

Bu :gger why didn't I think of adding the heavy base to the plastic tower

Your mention of oak has got me thinking, any offcuts of 2x1 upto 10 x 2 in hardwoods or mixed timbers would be workable to this design.

Thinking of adding leg supports.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

27th August 2005, 08:04 PM #7

Cool idea. Why did you do the splitting down the middle? Couldn't you have just drilled the holes all the way down?

Here how I solved a similar problem several years ago. Frees up bench space and creates a shelf at the same time Those are my principles, and if you don't like them . . . well, I have others.

Those are my principles, and if you don't like them . . . well, I have others.

-

27th August 2005, 08:24 PM #8

Zenwood,

My Forstener bits were not long enough, high speed drill were OK for length after initial forstener cut but our kitchen tool handles flatten out on the handles and the slots grip better.

Looks like you do some good cooking in Aus. woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

27th August 2005, 08:29 PM #9

Nah: just enough to keep alive

Nah: just enough to keep alive Originally Posted by jow104

Originally Posted by jow104

(except pancakes). Like everything else in our house, it attracts junk!

(except pancakes). Like everything else in our house, it attracts junk! Those are my principles, and if you don't like them . . . well, I have others.

Those are my principles, and if you don't like them . . . well, I have others.

-

27th August 2005, 10:14 PM #10

I'll wish you luck with it then... I'm an expert at stuffing up simple veneering, let alone something with holes to work around!

I'll wish you luck with it then... I'm an expert at stuffing up simple veneering, let alone something with holes to work around! Originally Posted by jow104

Originally Posted by jow104

Nar, toss the plastic! How 'bout combining zenwoods & peter's ideas and make a new tower with a bigger base, using cup-hooks to hang stuff? Or, if you have a lathe, turn a few spokes to hang the implements off. Come to that, hit the implement handles with a BIG hammer and replace them at the same time! Matched set...Bu :gger why didn't I think of adding the heavy base to the plastic tower

Especially if you have access to a lathe.Your mention of oak has got me thinking, any offcuts of 2x1 upto 10 x 2 in hardwoods or mixed timbers would be workable to this design.

Thinking of adding leg supports.

BTW, I've already pinched your idea. I did warn you! Using it to make a knife-block in which the handles recess a few cm.

- Andy Mc

-

28th August 2005, 06:49 PM #11

If you moved those big black and orange clamps to the bottom it would be stable

After that bloody coffee table I am now a veneering expert :mad:

Don't use PVA, use a good cross linked PVA, coat both surfaces, let it dry then iron it on, boom boom, simple as that, and don't use any spirit based stains or finishes as they dissolve the glue.Stupidity kills. Absolute stupidity kills absolutely.

-

28th August 2005, 09:45 PM #12

Iain

What do you mean by a cross link PVA?

I was intending to 10% water a genuine PVA glue, coat one piece of veneer drop side on, coat back side with pva and then drop veneer on. Any problems?woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

28th August 2005, 10:02 PM #13

Yellow glue as opposed to white, stronger and has better hanging on capabilities.

I glued up a buckled bead to a wall once and expected to get about three months out of it before it let go.

8 years later it's still there.Stupidity kills. Absolute stupidity kills absolutely.

-

30th August 2005, 12:54 AM #14

progress

progress

A kind member on the UK woodwork forum posted me a gift of veneers, some burr maple and silky maple together with some banding to complete my kitchen palette holder.

Ends in burr maple as per pictures and top palette holes veneered over and recut.

Hope to complete this evening when our tempertures coold down ( 30c in shop at the moment)

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

30th August 2005, 09:02 PM #15

Thats looking very good John but wheres the blinking scratch that you're building.

Similar Threads

-

Beginners Advise on old 'hoy' style boat building

By peterowensbabs in forum BOAT RESOURCES / PRODUCT SEARCHReplies: 4Last Post: 28th April 2005, 03:37 PM -

Guitar building

By Westie in forum WOODWORK - GENERALReplies: 4Last Post: 8th June 2001, 01:40 PM

Reply With Quote

Reply With Quote