Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 22

Thread: Very woody Christmas presents

-

16th December 2007, 06:51 AM #1

Senior Member

Senior Member

- Join Date

- Jan 2006

- Location

- sydney

- Posts

- 345

Very woody Christmas presents

Very woody Christmas presents

Each year my wife makes hampers for all the family that she fills with treats she makes herself, they're great but I kinda feel a bit left out...

So this year she has allowed me to add my contribution (and I think I'm going to steal the show...)

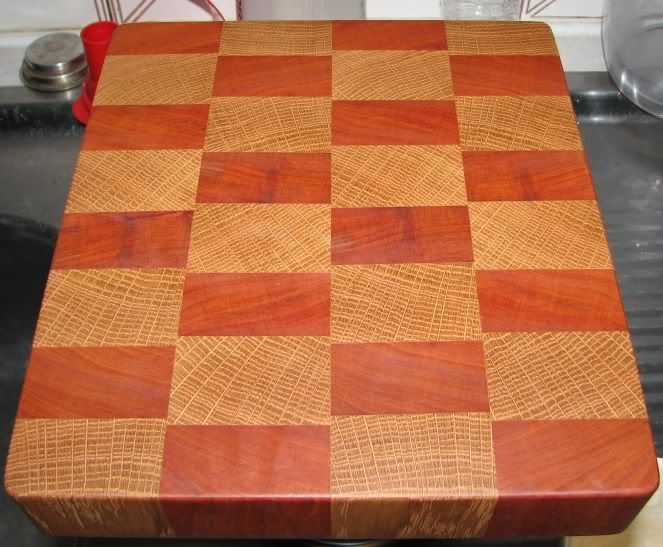

I made a small end grain breadboard to go into everyone's hamper from English Oak and Tassie Myrtle, I never knew Oak had such interesting end grain:

-

16th December 2007 06:51 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

16th December 2007, 06:55 AM #2

Senior Member

Senior Member

- Join Date

- Jan 2006

- Location

- sydney

- Posts

- 345

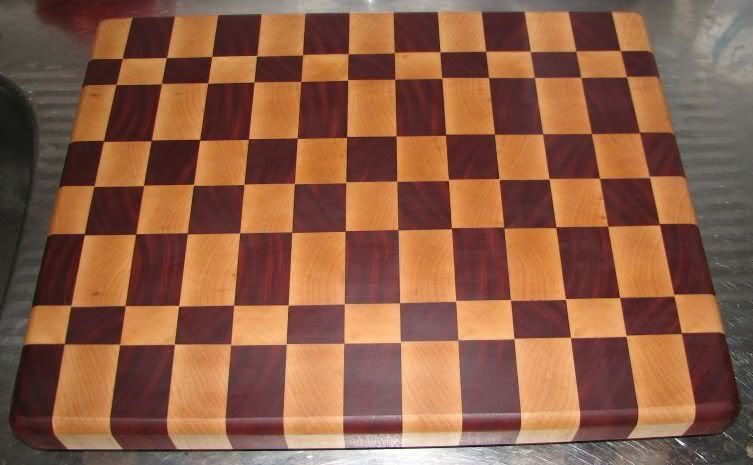

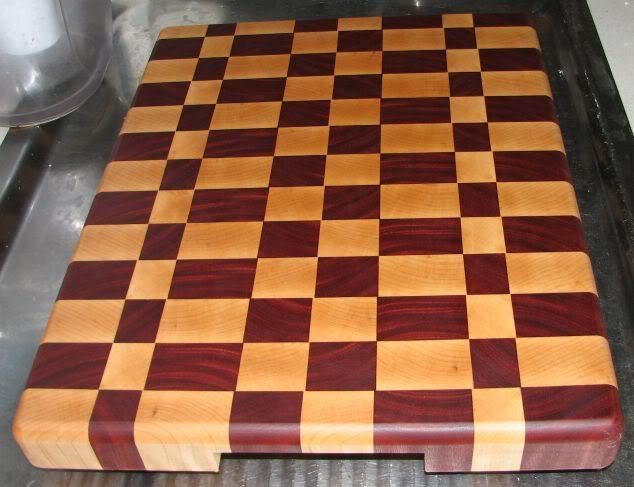

Then I made this one for my mother, purely because I wanted to try out something I saw on Youtube. It's supposed to be made from Maple & Purpleheart but the appropriate sized piece of Purpleheart was $80 so I settled for Maple & Jarrah.

It has 4 adjustable levelling feet & finished in about a thousand coats of woodwipe.

-

16th December 2007, 06:59 AM #3

They all look very good.

Pat

Work is a necessary evil to be avoided. Mark Twain

-

16th December 2007, 07:31 AM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Feb 2005

- Location

- Sydney

- Age

- 74

- Posts

- 1,389

Beautiful... and saleable as well

Beautiful... and saleable as well

Great work

Greg

-

16th December 2007, 12:36 PM #5

-

16th December 2007, 01:49 PM #6

You stole the show in my book MM. Nice.

In woodworking there is no scrap, only firewood.

Dave

-

16th December 2007, 02:01 PM #7

Wow, nice !!! Well done MM. I likes em. English Oak has some spectacular grain, and is pretty hard too.

Really like the one for your Mum. The different edge pattern, (block pattern) is great. She will be impressed.

By the way, what glue do you use for your boards? Your joins are seemless.

Must make a few myself one day with whats in the scrap basket.

Cheers

Pops

-

16th December 2007, 03:36 PM #8

Very nice, there will be some very happy people

-

16th December 2007, 05:51 PM #9

Senior Member

Senior Member

- Join Date

- Jan 2006

- Location

- sydney

- Posts

- 345

thanks for the kind words, glue used is Titebond II (thanks for the tip Wongo) and as long as your stock is well dressed you should get clean glue lines.

-

17th December 2007, 10:06 AM #10

Thanks MM.

Cheers

Pops

-

17th December 2007, 10:25 AM #11

Wow I am impressed MM. The English Oak and Tassie Myrtle are a perfect match. The colour of myrtle is so beautiful and of course the English Oak end grain. I do like it very much. It makes me feel great just looking at it. The one for your mum is very nice too.

End grain cutting boards are a bit harder and take longer to make. You’ve done really well there. If you don’t mind me putting a price tag on it. I reckon they are at least $100 to $150 each and nnd that is only a woody's mates rate. You can easily double that in the shop. No I am not talking about David Jones, they aren't good enough for this sort of stuff.

Lucky family you have there mate.

Wongo's rating:

Visit my website at www.myFineWoodWork.com

Visit my website at www.myFineWoodWork.com

-

17th December 2007, 10:52 AM #12

Great idea for prezies and very nicely done.

But here's a little thought. Don't put feet on them or handles then they can be used double sided. Twice the value and and not only that but you can use one side for cutting onion/garlic/chillies etc the other side for making sandwiches, buttering the toast etc and you don't get onion and garlic flavors permeating the toast and marmalade or the Boston bun, etc. Nothing worse.

Cheers - Neil

-

17th December 2007, 11:07 AM #13

Of course I totally agree with uncle Neil.

However, I think the handles are essential. Without the handles it is very hard to turn the board over. Your Jarrah board looks pretty heavy and a bit of rebate on the edges makes it easier to lift it up and flip it over.

What you can do MM is to cut the handles smaller and less noticeable. Do remember to one on top side and the other one on the bottom side. Otherwise you wonít be able to flip it back. Visit my website at www.myFineWoodWork.com

Visit my website at www.myFineWoodWork.com

-

17th December 2007, 12:18 PM #14

top job MM

....I agree with Wongo....the Myrtle and Oak are a great match

....I agree with Wongo....the Myrtle and Oak are a great match

cheers

BD

-

17th December 2007, 06:15 PM #15

Senior Member

Senior Member

- Join Date

- Jan 2006

- Location

- sydney

- Posts

- 345

Thanks fellas - that's a very flattering estimate there Wongo, if anyone else thought they were worth that much I'd buy me a drum sander and go into business...

I thought about making them double sided but I just couldn't sand any more, top is 320 grit bottom is 120. I normally set the handles in a little lower than that but I went silly this time. For double sided I would use stainless handles, the feet are there purely because they are adjustable to level my bad sanding job out.

Because I am using a Triton I get so much variation in each cut that when assembled the boards are all over the place and need lots of sanding. I'm saving up for a TSC10HB but it's a long way off yet...

Similar Threads

-

some Christmas presents

By ciscokid in forum WOODWORK PICSReplies: 1Last Post: 19th December 2006, 10:26 AM -

So many wedding presents..

By dalejw in forum WOODWORK PICSReplies: 9Last Post: 20th June 2006, 12:59 PM -

Presents ? What Presents ?

By Steve_DownUnder in forum WOODWORK - GENERALReplies: 9Last Post: 19th May 2006, 09:21 AM -

Early Christmas Presents

By journeyman Mick in forum Hatches, Matches & Dispatches. Birthday greetings and other Touchie-feelie stuff.Replies: 6Last Post: 25th December 2005, 05:59 PM -

Xmas presents

By simon c in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 18Last Post: 15th November 2004, 07:30 PM

Reply With Quote

Reply With Quote