Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 12 of 12

Thread: Homemade birdcage awl question

-

27th August 2019, 01:42 PM #1

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2018

- Location

- Melbourne

- Posts

- 507

Homemade birdcage awl question

Homemade birdcage awl question

I quite like the awl made from a masonary drill bit in the attached you tube. At the 2.37 minute mark he quenches the heated tip in some sort of liquid. From the looks and colour it is a light oil. Any thoughts on what the liquid is?

YouTube

-

27th August 2019 01:42 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

27th August 2019, 05:00 PM #2

I like his style.

However, I am not confident of that birdcage awl lasting long. He did not appear to temper the steel, and seems to have left it in a hardened stage. The tip angle looks about 10-15 degrees, which is too low to stand up to twisting.

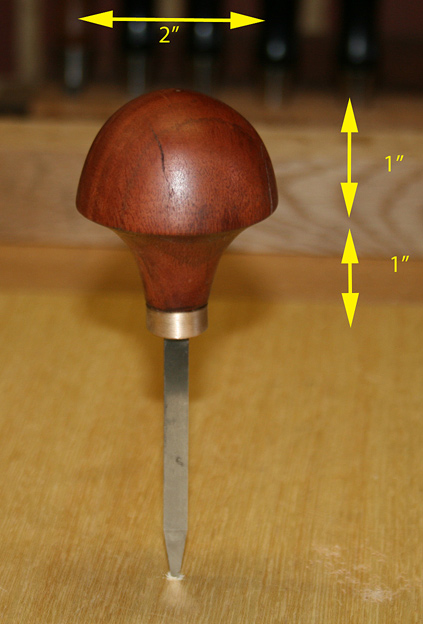

Below is one I designed and made several years ago. The shaft is solid carbide and the tip is 25 degrees.

The quenching liquid is likely either a light motor oil or a vegetable oil. I like Peanut Oil.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

27th August 2019, 05:47 PM #3

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2018

- Location

- Melbourne

- Posts

- 507

-

28th August 2019, 12:41 AM #4

I purchased the blade from Czeck Edge: Bird Cage Awls – CzeckEdge

That was 5 years ago, and I do not know if they sell the blade alone.

My review: http://www.inthewoodshop.com/ShopMad...rdcageAwl.html

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

28th August 2019, 07:39 AM #5

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2002

- Location

- NSW

- Posts

- 1,610

Huon Pine Fan,

he used olive oil

Screenshot_20190828-063405.jpg

-

28th August 2019, 07:59 AM #6

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2018

- Location

- Melbourne

- Posts

- 507

Very informative, thanks Derek

-

28th August 2019, 11:03 AM #7

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

For a WW hand tool, just Hardening is fine as gives maximum hardness and minimum wear.

The reasons for tempering are

- if the tool is going to be struck with mallet or hammer - fully hardened steels tend to be more brittle and can snap. Hardened steel is less brittle than most carbides.

- if the tool needs to be sharpened with a file or by other hand methods a slightly softer steel makes it easy to sharpen, if a grinder or sander are used there is no need.

-

28th August 2019, 11:07 AM #8

There were a few things I took from the video. The overall feeling was that you do not have to have sophisticated machinery to make such things and the emphasis on recycling a product.

I agree with Derek that the tempering process was not shown. For a high carbon steel, such as a conventional twist bit, this would be essential. However, this is a masonry bit and I am unsure what the carbide tips are bonded to. It may be that if the steel is a lower carbon (I am really guessing here) he might get away with it, but it certainly departs from the tried and tested method of annealing, shaping, hardening and tempering: All incidentally very easy to do with small pieces as a huge heat source is unnecessary.

I don't know about the angle. Again Derek makes a good point ( ), but the American timbers are generally not as hard as ours so again it may not be an issue. Just don't hoe into it on a piece of Ironbark, Desert sourced Acacias or Forest Red Gum to quote just a few.

), but the American timbers are generally not as hard as ours so again it may not be an issue. Just don't hoe into it on a piece of Ironbark, Desert sourced Acacias or Forest Red Gum to quote just a few.

I noticed he used Apple for the handle. Hard to get nowadays and that bit was still not large enough for a saw handle.

Just on the angle again and material for the blade, this is an ideal project for a used triangular saw file and of course they are available in a wide range of sizes ( I think I can see a set coming up in the future). As with discussions on another thread the teeth need to be ground off as they leave stress fractures, but as this tool is not subject to high speeds, unless you can twist it a lot faster than I can, it is unlikely to cause any grief even if it did snap. However, tempering is absolutely essential.

Now where did I put those pieces of Bull Oak and Hairy Oak?

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

-

28th August 2019, 02:00 PM #9

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- May 2018

- Location

- Melbourne

- Posts

- 507

Well I have an assortment of used saw files so it would be great to utilize one of them for a project like this

-

28th August 2019, 05:10 PM #10

Bob, birdcage awls need to be sharpened occasionally. The edges need to be treated like blades, as these cut when twisted, and blades need to be sharp. The twisting action will place a good deal of stress on the ability of the steel to be a little elastic and not crack when turned back-and-forth. Therefore I consider that it is important to temper the steel.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

28th August 2019, 06:11 PM #11

.

.

- Join Date

- Feb 2006

- Location

- Perth

- Posts

- 27,790

If TC works in this application then I don't see any difference between TC and the fully hardened steel. I doubt the TC has much elasticity, or that any wood would challenge a fully hardened piece of steel any more than it would a TC tip.

In terms of the overall tool a solid shaft of TC is likely to be less elastic and more brittle that a steel rod with just the tip hardened. It's not like the 90º cutting parts of the blades are very fine anyway. Brittleness is only really a problem for struck tools or tools used on machinery that might catch eg like old files on lathes, and would be an issue for both TC and hardened steel if a tool was dropped say onto a concrete floor. Sharpening on a sander or grinder or a bit of wet and dry, even when fully hardened could be achieved without any problems. Sharpening a TC will require a green or diamond wheel.

-

1st September 2019, 12:19 PM #12

I had the opportunity to anneal some high carbon steel (used triangular files) last night. Normally I would do this in the slow combustion heater, but it is not quite cold enough at night to warrant a fire in the house. The window of opportunity has passed for this year and in fact was very brief compared to previous winters. Our daughter and partner visited and it was an excuse to run the chimenea: It is plenty cold enough outside at night at this time of year and in this part of the world.

I did stoke it up a bit more than usual, but this was because I was just burning offcuts of Cypress Pine and not the Ironbark that is used in the combustion heater. I was not 100% confident this timber would be hot enough:

P1050438 (Medium).JPGP1050437 (Medium).JPG

This morning everything had cooled down, but still too hot to handle as ash holds heat for a long time.

P1050439 (Medium).JPG

I used a strong magnet on the end of a pair of tongs to prise the files from the ash.

P1050443 (Medium).JPG

Quite a few files:

P1050446 (Medium).JPG

The magnet also retrieved a quantity of nails from the demolition timber .I also know where my BIL threw his bottle tops after an earlier evening

.I also know where my BIL threw his bottle tops after an earlier evening

P1050447 (Medium).JPG

These are the files with the ash brushed off:

P1050448 (Medium).JPG

How do you know if the metal has been annealed? Hit the steel with a hammer. If it deforms it is annealed; If it breaks, you did not get the fire hot enough. This is a flattened corner:

P1050449 (Medium).JPG

The final test is whether you can bend the steel. I put the file in a vice and hit it with the hammer.

P1050451 (Medium).JPG

All good! . Ready to find some time and actually make something.

. Ready to find some time and actually make something.

The object of this exercise was to show you don't need a furnace or forge for this part of the operation.

Regards

PaulBushmiller;

"Power tends to corrupt. Absolute power corrupts, absolutely!"

Similar Threads

-

Homemade Chisels!!

By SquidLYF in forum WOODTURNING - GENERALReplies: 8Last Post: 21st May 2013, 11:29 AM -

Help! Homemade Railway Sleeper Table + Creosote Question

By Knockawaddra in forum FURNITURE, JOINERY, CABINETMAKING - formerly BIG STUFFReplies: 5Last Post: 3rd November 2010, 08:32 PM -

Birdcage sidechair.

By JDarvall in forum WOODWORK PICSReplies: 19Last Post: 13th August 2009, 09:19 PM -

My Homemade cnc

By simso in forum CNC MachinesReplies: 18Last Post: 25th October 2008, 03:58 PM -

homemade steam box

By mrpotter in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 4Last Post: 19th October 2006, 12:36 AM

Thanks:

Thanks:  Likes:

Likes:

Reply With Quote

Reply With Quote