Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 20

Thread: Marking triangles

-

2nd November 2007, 08:02 AM #1

Deceased

Deceased

- Join Date

- Jan 2006

- Location

- poland

- Age

- 78

- Posts

- 761

Marking triangles

Marking triangles

G'day mates

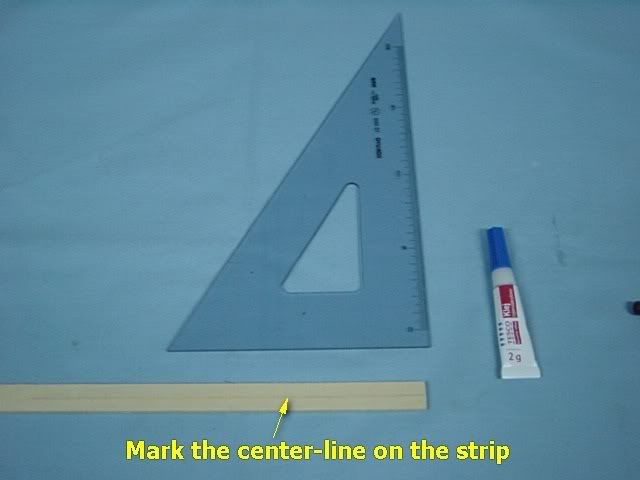

I found those plastic drawing triangles very, very accurate so, instead of buying one of those metal marking triangles..that are changing "moods" according to the season (and from checking them in the shops - not so accurate), I made them from more stable materials like plywood or plastic.

For the base, you can use any man-made board like, plywood, MDF or even "floor panels" because they have very consistent thickness.

Usually, I use 8 mm floor panels for the big triangles but, for that one on the pics that is 2mm thick, I used 4 mm plywood

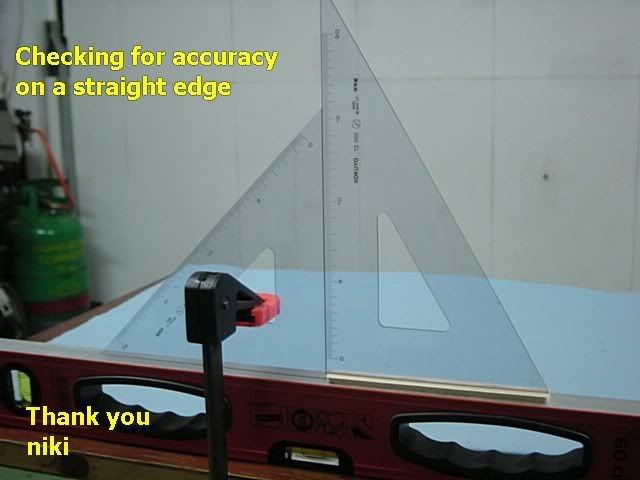

After the modification, you can still use the triangle to check for squareness.

And the rest is very simple...

Regards

niki

-

2nd November 2007 08:02 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

2nd November 2007, 08:11 AM #2

Thank you Niki.

However can I set you a task?

I want a straight edge around 1 metre long, that is accurage to .000.

and can be used to check out things like my thicknesser tables.

Suddenly thought of an idea myself. how about a length of taut string stretched to a nail each end of a batten and looking like a bow saw.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

2nd November 2007, 08:35 AM #3

Deceased

Deceased

- Join Date

- Jan 2006

- Location

- poland

- Age

- 78

- Posts

- 761

Thank you DW

Yes, it's a great idea but I think that it's better if the string will pass below the sticks so when you put it down on the table, it will be at the same level.

Regards

niki

Attachment 59201

-

2nd November 2007, 09:33 AM #4

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2007

- Location

- Nicholls ACT

- Posts

- 728

That will highlight depressions but may not show up bump to the accuracy you want as the string could deflect slightly without you knowing. Even depressions might be hard to spot the relative fuzziness of string. Or am I missing something.

Pusser

-

2nd November 2007, 06:35 PM #5

OK Pusser, so we need a new idea.

Any takers?woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

2nd November 2007, 06:52 PM #6

shame you couldnt tie a string between the bottom string and the centre as this would droop'/slacken off if there was any depression.

-

2nd November 2007, 07:09 PM #7

If the string and holding setup was longer than the piece being tested it would make both discreptancies stand out. ?

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

2nd November 2007, 11:38 PM #8

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2007

- Location

- Nicholls ACT

- Posts

- 728

Sorry to be negative but my solution was to buy a 1 metre strait edge and some feeler guages.

When I used a triton i used a laser pointer with a series of targets on a wooden base and just jacked up the adjustable legs until the laser passed through the holes in the centre. It was ok but is an alignment test rather than a flatness test. The accuracy required which I interpreted to be better than 0.0004mm is tough even with a straight edge. Trying to sight a gap under string would be a tough ask and a few thou bend in the string is going to be nigh on impossible to see.

Pusser

-

2nd November 2007, 11:58 PM #9

Sorry Pusser no spending allowed.

woody U.K.

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd November 2007, 08:17 AM #10

Awaiting Email Confirmation

Awaiting Email Confirmation

- Join Date

- Jan 2007

- Location

- Goulburn NSW

- Age

- 89

- Posts

- 913

I use my 1 meter level as a straight edge didn't buy it.... it's been around for years

les

-

3rd November 2007, 07:04 PM #11

Les, I also have got a 1 metre ruler, reasonable quality, but it sags, drops down at the ends to take a rest.

So when I lay it across the P/T it gives me a true reading which I suspect is false.woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

-

3rd November 2007, 07:11 PM #12

Looks good. But just quietly, I reakon you should grind a plough blade to plane a trench that gives you a tight fit for those set squares.....say 3-5mm deep then slot them in with that glue. But thats just an opinion. Be other ways too I'm guessing.

-

4th November 2007, 01:25 AM #13

Deceased

Deceased

- Join Date

- Jan 2006

- Location

- poland

- Age

- 78

- Posts

- 761

Thank you Apricotripper

I did it on two of my triangles but for some reason, after some time the setting (squareness) changed...maybe because I used Pine as a base...

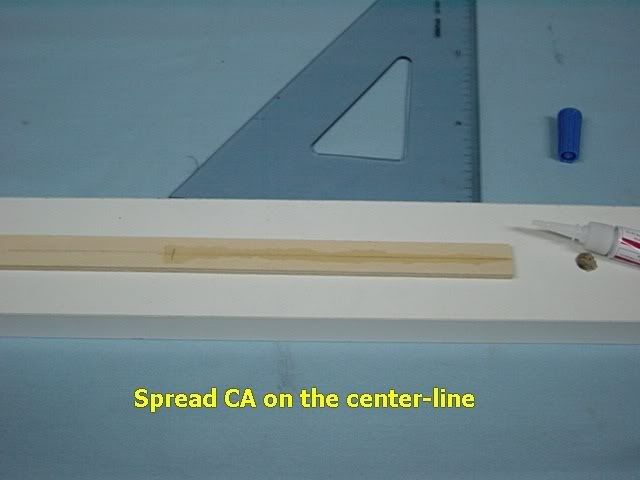

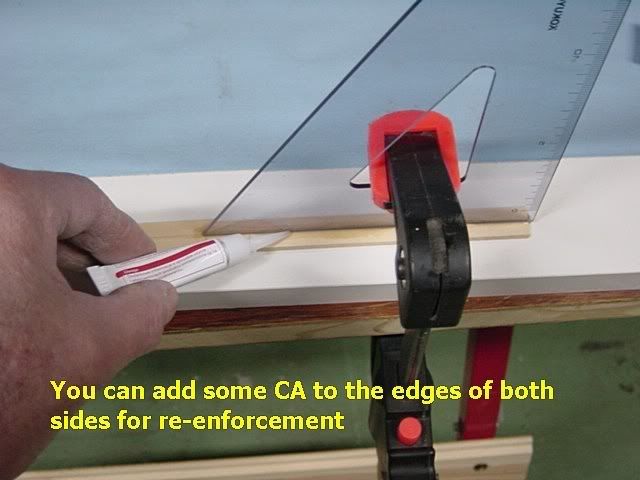

Later, I thought that it's too much work to make the base very consistent in width (so I'll get square from the inner and the outer side of the base) and to make the slot on the router table so, I thought that plywood, MDF or "floor panel" are very flat and consistent in thickness and gluing it with CA (super glue) will be strong enough.

The plywood triangles are 6 mm thick that I made 2 months ago and nothing broke or changed.

Yesterday I tried to break the plastic one and it looks very strong...

Regards

niki

Attachment 59364

-

4th November 2007, 06:43 PM #14

Why not just laminate a slat on each side of the triangle, so the plastic edges are still the references?

That way, any variation in the wood thickness shouldn't affect the angle.

- Andy Mc

-

4th November 2007, 07:33 PM #15

I hope niki doesn't mind me hijacking into his thread again but what Skew has written could apply to my steel 1 mtr. ruler. I could laminate a piece of ply to the steel to reduce zagging?

woody U.K.

"Common looking people are the best in the world: that is the reason the Lord makes so many of them." ~ Abraham Lincoln

Similar Threads

-

Marking knives

By derekcohen in forum HAND TOOLS - POWEREDReplies: 43Last Post: 9th July 2006, 08:33 AM -

Marking knife for skinny dovetails, and a set screwdriver

By derekcohen in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 2Last Post: 16th August 2005, 12:40 AM -

Weird marking gauge

By JDarvall in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 4Last Post: 25th July 2005, 04:24 PM -

Sturdee's marking gauges.

By Sturdee in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 57Last Post: 26th April 2005, 08:40 PM

Reply With Quote

Reply With Quote