Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 53

Thread: Reverse angle shooting board

-

13th December 2011, 09:44 PM #31

gravity is my co-pilot

gravity is my co-pilot

- Join Date

- Apr 2010

- Location

- Melbourne

- Posts

- 562

-

13th December 2011 09:44 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

14th December 2011, 02:36 PM #32

Not saying a lot about ramp up or down as my board is the lazy man flat sort. One thing about shooting boards is that the edge of the plane sole rides along the edge of the bed so where there is space under a ramp then the bed will get planed away. That first pic shows a gap where the plane sole edge has nothing to contact. May be ok for a longish plane but I would be filling that in with a wedge if it were my board.

Regards

John

-

14th December 2011, 04:36 PM #33

I'm not sure I agree with your reasoning. With end grain to end grain glueing I think you want the glue to reach down into the wood fibres (which are like tubes) and then cross link across the joint. If the ends of these tubes are cleanly cut the ability of the glue reach into the tubes should be improved compared to rough ends. Then again, depending on you choice of glue, the whole question maybe accademic.

I'm with John on this,regards from Alberta, Canada

ian

-

14th December 2011, 07:06 PM #34

Of the two options, the sawn mitre surface would be stronger than the shot mitres, but I think this difference would be marginal, & neither would withstand any hard knocks without some reinforcement such as keys. Additionally the shot mitre is more likely to produce a neater joint.

Regards

-

14th December 2011, 08:28 PM #35

Smooth surfaces are better for glueing. Rough sawn edges will present less glueing area where they join, which is an issue for non-gap filling glues.

Smooth surfaces are certainly going to create a tighter and cleaner fit ... which is what you want on mitres.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

14th December 2011, 10:48 PM #36

Two things are infinite: the universe and human stupidity; and I´m not so sure about the universe.

Two things are infinite: the universe and human stupidity; and I´m not so sure about the universe.

-

14th December 2011, 10:57 PM #37

Hi Phil

I was assuming - since we are talking hand tools - that the saw you were referring to was a handsaw. My guess now is that you meant a power saw. A handsaw, unless Japanese, will leave teeth marks. These are not flat like those sides off a plane.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th December 2011, 08:13 AM #38

Yes I should have clarified I was talking about off the table saw, or a nicely executed cut with a fine handsaw such as a dozuki.

The joints will hold fine without keys, on boxes and such, but they will open up if they are dropped or suffer a hard knock ( I can attest to that )

Regards

-

15th December 2011, 08:18 AM #39

A saw is a saw is a saw Derek so long as it is nice and sharp they all do the same job except one makes a bit more noise and is less effort to use.

From an engineering point of view that is. I think I did mention that I use a table saw Derek.

From an engineering point of view that is. I think I did mention that I use a table saw Derek.

BTW I am quite familiar with hand tools I made all my own by hand and some help from machines when I was a first year apprentice. I can still remember hand filing a perfectly square 1" x 1" x 1" mild steel block, sorts the men from the boys.

I still have the tools, the 6V series DC motor I made from scratch still sits on my bookshelf, we were not allowed to glue a coin showing the date under these so we used washers with the date stamped in instead.

Last edited by Phil Spencer; 15th December 2011 at 03:25 PM. Reason: Shouldn't type with out my specticles!

Two things are infinite: the universe and human stupidity; and I´m not so sure about the universe.

-

15th December 2011, 08:26 AM #40

-

15th December 2011, 08:38 AM #41

-

15th December 2011, 09:26 AM #42

Don't know where the block is now wish I still had it.

Still use most of the tools, some of the clamps need a bit of attention to remove some surface rust

As a snotty nosed apprentice earning $18.00 per week I couldn't afford to waste money, I learnt the value of the coin of the relm then,

I am still a tight A## and just can't fathom throwing money away by gluing it to bits of wood (what is that saying? look after the pennies and the pounds look after themselves) so I use washers instead.. I could go on for hours about people who throw money away, I find it some how offensive.

Regards[/quote]Two things are infinite: the universe and human stupidity; and I´m not so sure about the universe.

-

15th December 2011, 10:45 AM #43

i mentioned the 6V DC Series motor I made as an apprentice I know this is off topic here are some pictures.

Two things are infinite: the universe and human stupidity; and I´m not so sure about the universe.

-

15th December 2011, 02:56 PM #44

Hi Phil

A handsaw does not leave the same kerf as a power saw in my experience. The handsaw will leave a slightly ragged surface, and this is why it needs to be planed flat.

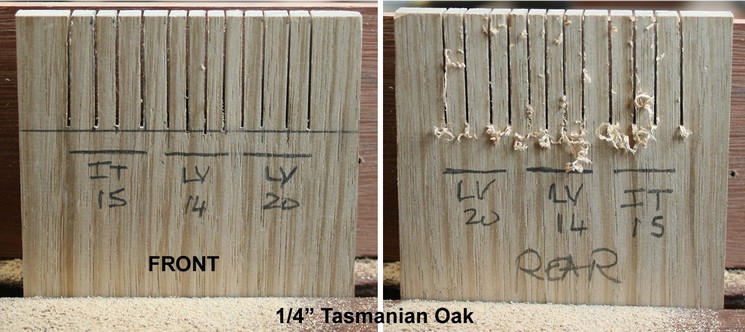

Here are some images I took when comparing the LV 20 pip and 14 pip dovetail saws and the IT 15 pip dovetail saw.

First vertical rip cuts were made ...

.. and then these were cut open to reveal the surface of the kerf ..

On a mitre, such as a picture frame, I would want to plane that flat. By contrast, if I used a table saw, I would get a smooth, glassy finish that, if the angles were accurate, could be joined as they were.

Regards from Perth

DerekVisit www.inthewoodshop.com for tutorials on constructing handtools, handtool reviews, and my trials and tribulations with furniture builds.

-

15th December 2011, 06:35 PM #45

gravity is my co-pilot

gravity is my co-pilot

- Join Date

- Apr 2010

- Location

- Melbourne

- Posts

- 562

I'm sticking to flat shooting boards from now on. After reading all the excellent posts, I've decided I don't wish to push a plane against an uphill piece of wood (did I say wood?)

Have we explored the drag coefficients of various planes, and the surfaces on which they run? I presume that the shiniest planes set up a vacuum, and end up 'locking-on'?

cheers,

B-D.

Similar Threads

-

Shooting board

By Basilg in forum HAND TOOLS - UNPOWEREDReplies: 21Last Post: 28th January 2012, 05:01 PM -

Shooting Board

By SHIPPERS in forum WOODWORK - GENERALReplies: 2Last Post: 7th December 2007, 09:08 PM -

shooting board

By forunna in forum WOODWORK - GENERALReplies: 3Last Post: 27th April 2004, 12:32 PM

Reply With Quote

Reply With Quote