Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 38

Thread: Anvil-vise anyone seen one?

-

8th April 2012, 11:56 AM #16

Member

Member

- Join Date

- Jul 2008

- Location

- Sydney Australia

- Posts

- 81

Silversmiths Vice ?

Silversmiths Vice ?

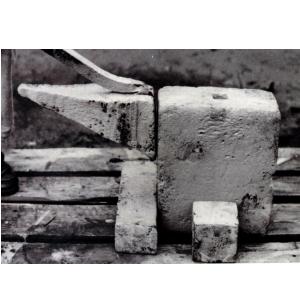

This sold recently on a popular online auction site for $20 - only one bidder and it wasn't me

cheers,

greg

-

8th April 2012 11:56 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

8th April 2012, 04:33 PM #17

Someone at the Toowoomba swap this year had a blacksmiths vice/anvil/geared drill/grinder..... i cant remember the specific name of this type but

happy turning

happy turning

Patrick

-

9th April 2012, 03:59 PM #18

Nice Phil but besides the point. You have an interest in old tools, that does not mean they are better than new quality tools.

Steam engine? Coke forge? Bellow? All nice stuff for a person like you or a museum.

I also like old stuff, in fact I am int the market for a Ford model A and already own a Buick 1929. The brakes on the Buick are actioned by steel rods and the braking action is from outside the brake drum. Love it.

Yet I wouldn't go to work every day on it nor pull my boat with it.

And the same applies to the tools you display rightly with pride.

Look up for real blacksmith in the 21 century and you will have to look up the US or Europe. Then look at the one actually doing some work and the tools they use.

True there are hardly any blacksmith in Australia. Not sure why but that explains how useless clumps of metal get sold on e-bay for premium prices and get the name of anvils.

As for the cost of new tools, again besides the point completely.

An amateur can work with old tired tools and get them to work. He will probably learn a lot from the exercise. A tradesman buys good reliable modern tools every time because he needs to make a a profit. Unless...he really likes the old stuff...

Yet you will agree it is hard to make a profit working on a sunken rounded old boat anchor or a coke forge. Buy a gas forge, a new anvil (or fix your old one and good luck with that) or make yourself a new anvil. "The only tool you can not do yourself?"

Come one ...

I like your display, and I am sure you can even produce fantastic stuff.

Yet that is not the way of today's blacksmithing, that is nostalgia and love of the old ways like me and vintage cars or boats.

I doubt you would be impressed if you go to the dentist and he has a pedal powered drill.“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

9th April 2012, 04:09 PM #19

How to make an anvil

anvilfire.com is probably the best website for professional blacksmith and serious amateur.

http://www.anvilfire.com/21centbs/an...hing%20article

How to buy an anvil

http://www.beautifuliron.com/gs_anvils.htm“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

9th April 2012, 04:30 PM #20

Hi Marc,

You have to know who to talk to and where to look.. Australian Blacksmiths Association (Vic) Inc. - Welcome

I've dabbled in blacksmithing, and have ambitions to learn the craft, but I've yet to progress beyond flattening hot bits of metal without much planning or skill.

There's no better therapy than whacking away at red hot bits of metal, I'm not sure you'd call what I do blacksmithing, but it's good fun.

I've seen the blacksmiths shop where Phil works and the quality of the work is outstanding, it's good to see the skills being preserved.

Regards

Ray

-

9th April 2012, 04:41 PM #21

Yes I knew of the Melbourne association and I think there is another in Perth (?)

I have no doubt that many old school blacksmith do great work with old tools. My blacksmith master during my apprenticeship back in the 60ties was one of them.

Yet he would use a MIG and an angle grinder and a gas powered forge if he had them available as they are today. And if his Swedish anvil would sink in the center and round the edges, do you think for a minute he would have gone to the trouble of "fixing" it? No way. Out to the scrap merchant and in with a brand new Swedish . . .

Nothing has changed today,

"New anvils are now cheaper than used anvils. Prices of used, broken, chipped, worn-out, poorly repaired(?) anvils at auctions in the U.S. have been bid up so high as to make buyers of those used anvils look like the proverbial village idiot. Prices at auctions are now higher than the prices of new anvils of the same or heavier weight. Know the prices of new anvils before buying a used anvil at auction. Check out the prices at the distributors linked lower on this page." http://www.beautifuliron.com/gs_anvils.htm

Shipping an anvil from the US is a non issue, just a matter to get informed and try a fright forwarder that is keen. Try not to ship them airmail next to a bouquet of orchids and you will be fine.

You can start with myus.com or ibcinc.com

As for your interest in red metal...good for you.

Go to anvilfire.com and look for the iForge demonstrations to start with

http://www.anvilfire.com/iForge/“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

9th April 2012, 05:02 PM #22

And for the record here is another brand new series of nice spanking new anvils.

Nimbus is the name, Italian style made in the US

“We often contradict an opinion for no other reason

“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

9th April 2012, 05:08 PM #23

And if you really must buy Australian, you can.

Doug Slack Foundry in Emerald Queenslad makes anvils from time to time. They have 2 molds, one 42 and one 90something kilos I think.

You will have to send it for heat treatment if you want to work them hard and want them to last.

I have two of theirs and they are OK“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

10th April 2012, 02:30 PM #24

son of a blacksmith

son of a blacksmith

- Join Date

- Jun 2011

- Location

- Roxby Downs Sth Aust

- Age

- 47

- Posts

- 254

ive been around blacksmithing and smithy's my entire life and one thing i can say about the old / worn anvils is that they have character and not in the way Benny Hill did. each rounded edge, concave, worn / flogged out prichard hole allows for far more versatile anvil. how many old smithys ive heard say they prefer their old anvils to a new one with sharp edges? all of them. if you want to cut steel on an anvil use a hardy chisel not the edge of the face.

my old peter wright anvil made circa 1865 225lbs has a range of different radii on one edge, you can't buy that, that's150 years worth of love there.

there's no comparison between a vintage car and a modern car (in terms of technology), thats a given but when comparing tools/tooling, just ask a few of the hercus fellas here.im no machinist but quality will always stick out like dog's balls and should even be obvious to those that are impressed by shiny new things.

-

10th April 2012, 07:17 PM #25

You bring up a few issues of mainly personal nature.

Old anvils have "character"

Benny Hill does not.

Round edges on the anvil are handy

Concave work surface is versatile

Fools who can't really see quality or dog balls, are impressed by shiny new things.

Hum...

what can we use out of the above statements.

Not much.

There will always be a market for old tools and wood work or metal work tools are no exception

I have never seen anyone putting up an argument that wood block planes are "better" than modern metal jack planes, however wood block are pricy and collectable yet no carpenter in his right mind would show up at the building site with one in the tool box.

The same goes for blacksmithing tools of old. When they are usable and they make some good starting point for hobby metal workers, they are no match for new quality tools for a professional or serious hobbyist.

And this is probably the sticky point.

Who is a professional blacksmith?

What is quality?

Blacksmithing is old hat and therefore associated with old tools. A blacksmith can make a living with museum pieces and so "keep the craft alive"

Yet blacksmithing is not black magic and like any other trade of technical nature, requires skill technique tools and renovation.

One can turn green wood under a tree with a pedal powered lathe of sort and claim it is the best in the world, yet a better job can be done with an electric lathe inside a shed.

Not romantic enough?

Sorry, perhaps should take up painting or playing the violin.

Old tools are OK providing the time they have served has not taken away their qualities. To say they have improved is rather naive and you are probably comparing apples with oranges.

Yes you can buy some good old anvils.

Here are some Anvils for sale

Are they value for money?

Not for a minute, check out the prices!!!!

You can do better with new quality anvils, check out the list of manufacturers in my previous post.

In Australia you will be hard pressed to find any good anvils at all, simply because we lack the hundreds of years of tradition other countries have.

And the proof is in this thread were some cling to old clumps of metal that only have the scars of the battles to show and should have retired to the living room coffee table a few decades ago.

But hey...I respect anyone who is able to make anything useful with a sunken rounded anvil.

Just don't say they are "better" than a new one because that is not true, was never true and will never be true as long as manufacturers deliver better and cheaper new anvils.

Chinese origin excluded of course.“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

10th April 2012, 07:26 PM #26

“We often contradict an opinion for no other reason

“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

10th April 2012, 08:07 PM #27

A bit of blacksmith work on an OLD German anvil

did I mentioned old?

did I mentioned old?

German Anvil forging demonstration - YouTube

How to make your own anvil

ANVIL MAKING“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

10th April 2012, 08:09 PM #28

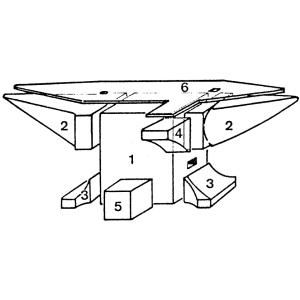

The elaborate hand forged double horned anvil is efficient for the blacksmith and is in itself an artform. In the middle ages a simple steel block was the typical anvil.

The elaborate hand forged double horned anvil is efficient for the blacksmith and is in itself an artform. In the middle ages a simple steel block was the typical anvil.

With the development of more artistic blacksmithing in each village, a more efficient and better quality anvil was required.

Many attempts were made to make anvils from cast iron and steel. These early attempts failed due to poor quality of the castings.

Up until 1956 the blacksmith anvil was made of many parts forged and fire welded together.

The various individual parts comprising the horns (2), the feet (3), the side shelf (4), and the heel (5) were all fire welded to the main body called the Luppe (1). For example, the Luppe was heated in a main coal fire and the foot was heated in a separate fire used just for individual parts. After both reached welding temperature the pieces were put together and forge welded by the sledge hammers of 4 to 6 blacksmiths.

Up to this point, the anvil was made of iron which could not be hardened and was called “puddeleisen” ,puddled iron, or wrought iron.

Now came the most importand and heaviest part of the forging work, the forge welding of the steel plate (the anvil face (6)). This work was done by 6 to 8 anvil smiths each with heavy sledge hammers hitting around the plate in turn. The plate had to be welded without stop in 15 minutes. It was better to have 8 men as then each man had a little longer to rest between blows. After completion of the face welding, the men flattened and straightened the anvil with their hammers.

The last shaping step was the filing of the round horn with a 2 meter (6 foot) long file. This was held by two men. All this was done hot as it was easier than if it were cold.

The next major step was to plane/polish the anvil face. This was done on a stone wheel 6 feet in diameter.

For all this work the machinery was powered by waterwheels. One waterwheel ran the drop hammer used to forge the various parts, one waterwheel ran the stone wheel, and one waterwheel ran the blower for the fires.

The last part of the work was to harden the anvil-face by cooling the hot anvil in water. 20 tons of coal were used every month for their daily forgings. Using these methods and factory, they made anvils up to 550 kg. or 1215 lb. The only devices the men used to manhandle the big anvils were iron rods used as levers. They also utilized leather rags to keep the heat from their bodies.

Due to improvements in casting iron, since 1956 the old forged anvil body was replaced by a one piece cast iron forging. The casting was still faced by the fire welding of a top plate using the traditional method. Since 1975, technology improvements have allowed anvils to be made entirely of cast steel. The face is still hardened in the traditional mannerie, heated in a coal forge, and quenched in water. This process allows for an anvil of a consistent quality that is superior to previous anvils. It also results in a face that is as hard as the fire welded plate, but hard to a much greater depth.

Ernst Refflinghaus | [email protected]“We often contradict an opinion for no other reason

than that we do not like the tone in which it is expressed.”

Friedrich Nietzsche

-

10th April 2012, 08:12 PM #29

So you are a blacksmith then Marc?

-

10th April 2012, 08:15 PM #30

Or do you just have some strange ideas about double horned anvils- copying and pasting doesnt really impress anyone. How about taking on board what other EXPERIENCED people have to say rather than your attitude of its my way or the highway.

Similar Threads

-

repairing an anvil

By kraits in forum METALWORK FORUMReplies: 5Last Post: 30th June 2011, 11:06 PM -

Railway iron anvil

By xcam in forum METALWORK FORUMReplies: 7Last Post: 30th July 2008, 01:50 AM -

Rail iron anvil

By Andy Mac in forum HOMEMADE TOOLS AND JIGS ETC.Replies: 2Last Post: 26th October 2005, 11:34 AM -

Anvil wanted in Melbourne

By Auld Bassoon in forum HAND TOOLS - POWEREDReplies: 12Last Post: 25th October 2005, 11:51 PM