Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 15 of 19

Thread: CNC End Mill Cutters

-

6th March 2012, 09:06 PM #1

CNC End Mill Cutters

CNC End Mill Cutters

Hi all

I am after a bit of advice please, I have HM46 Mill and have purchased

7pce. 4 fluted tiain carbide end mill cnc cutters.

I am wondering now if these are ok to use on my mill, the feed is by hand I have only noticed that it states CNC not sure if that mean I cannot use them on a conventional hand operated mill I do not have a lot of experience in this area any advice appreciated thanks

Colbra May your saw stay sharp and your nails never bend

May your saw stay sharp and your nails never bend

-

6th March 2012 09:06 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

6th March 2012, 09:19 PM #2

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2007

- Location

- sydney

- Age

- 64

- Posts

- 3,566

They will be ok.

-

6th March 2012, 11:54 PM #3Dave J Guest

As Pipeclay said they will be fine, do you have a link to what you bought so we could have a look and give you some more advice.

Dave

-

7th March 2012, 08:59 AM #4

Thanks Dave & Pipeclay here is a copy of my latest purchases

Thanks Dave & Pipeclay here is a copy of my latest purchases

that may be of interest to you Dave and other

eBay Australia: Buy new & used fashion, electronics & home d

eBay Australia: Buy new & used fashion, electronics & home d

eBay Australia: Buy new & used fashion, electronics & home d

Col May your saw stay sharp and your nails never bend

May your saw stay sharp and your nails never bend

-

7th March 2012, 05:34 PM #5

Hi Col,

Quite a few of us buy tooling from CTC, and it's generally pretty reasonable quality, it pays to check his website, sometimes the prices are different to his ebay prices.

That carbide end-mill set you got from ebay is $113.77 if you buy from his web site. Results for Cutting Tools arbide Endmills:Sets

arbide Endmills:Sets

I've been using some of the CTC solid carbide roughing cutters, and they rip through mild steel like nothing... 4 FLUTE CARBIDE ROUGHING ENDMILL CUTTER - METRIC #H50

Regards

Ray

PS.. Anyone have any idea as to how a smilie popped up in the middle of a url? A bug in vbulletin?

-

7th March 2012, 07:01 PM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2007

- Location

- sydney

- Age

- 64

- Posts

- 3,566

No.

-

7th March 2012, 07:12 PM #7

options

options

Maybe this is a cheaper option ?

4 FLUTE HSS M2AL ROUGHING ENDMILL CUTTERS (6 PCS) - METRIC #H01

-

7th March 2012, 07:43 PM #8

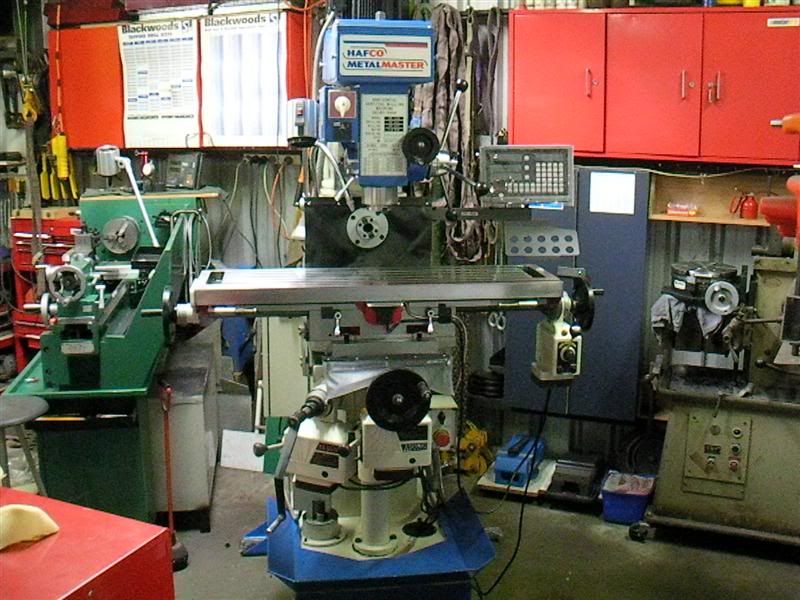

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

-

10th March 2012, 07:48 PM #9

Hi Ray it is my understanding that the cutters you purchased ROUGHING ENDMILL CUTTERS will remove material easier and faster than straight 4 fluted mills, as the ones I spoke about, am I on the right track with this thought also what would be a sensible amount material to remove when cutting mild steel bar or the equivalent with my mill HM 46

Please keep in mind this is only the start of my journey with steel or such like I generally PM Dave with all my questions just in case I am out of order with my ideas on things.

Thanks Col May your saw stay sharp and your nails never bend

May your saw stay sharp and your nails never bend

-

10th March 2012, 09:50 PM #10

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2007

- Location

- sydney

- Age

- 64

- Posts

- 3,566

Are you asking if using roughing cutters or end mills/slot drills.

-

10th March 2012, 10:23 PM #11

Hi Col,

Yes exactly that, the roughing end mills are just a bit more aggressive for removing a bit more material, they usually have serrated flutes, versus smooth flutes on the normal end mills..

The ones I've tried leave a reasonable finish as well, but you won't go wrong with the ones you've already got on order. They will work just fine.

There is a thread here by .RC where he has a video of a 20mm cut he did using a rippa end mill. https://www.woodworkforums.com/f65/ri...-mills-145498/

Regards

Ray

As far as the sort of depth of cut you can expect with the carbide mills on the HM46, I'd start at maybe 1mm and increase from there to see how it goes. Maybe someone with a Hm46 could give a better answer...

-

10th March 2012, 10:59 PM #12

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2007

- Location

- sydney

- Age

- 64

- Posts

- 3,566

From what I have read from members responses here who have the Dovetail type mills they are limited as to there depth of cut,it appears that the dovetail column type is not as ridgid as the round column type.

The size (diameter and length of the cutting tool will also have an effect on the depth of cut.

The speed will have an effect.

The feed rate will have an effect.

The type of material will have an effect.

How the swarf is evacutated from the tool can also have an effect.

If the cut is captivated or open will also have an effect.

Generally the smaller the cutter the less the depth of cut but the greater the speed and vice a versa.

Climb or conventional milling will also have an effect.

-

11th March 2012, 02:11 AM #13Dave J Guest

Hi Col,

For smaller machines (even mine) the roughing cutters are good for removing a lot of material quick, then change over to a normal end mill to finish with. As for how much it will cut Pipeclay pretty well nailed it all, as there are so many variables in milling machines and material.

Start off with the right speed and feed and if the machines seems to be doing it easy load it up a bit more until you feel the machine is pretty well at it's limit. With a 2 hp motor, this will be you machine starting to shake around.

Of course this is only for removing large amounts of material, but even if you doing a light cut remember to keep the feed up as going to slow will kill cutters by rubbing and not cutting.

With CTC you will always find you save a bit buying through his shop instead of ebay. He adds the fees and a little more to each transaction. You are still safe buying through the shop as you still pay by paypal.

What you have will keep you going and if you look after them they should last quite a while. Coolant is a milling cutters best friend, and with it running you will make the cutters last much longer as it also washes away the swarf instead of re cutting it. Even if you have a simple 20 ltr drum to drain it back into and then when your not using it put the lid on it to keep it.

On a lathe you can easily get away without coolant because the tools can be easily re sharpened, but a mill really needs coolant if you want your cutters to last longer because as you know it's probably worth more than the Chinese cutter to get it re sharpened.

Dave

-

11th March 2012, 08:52 PM #14

Thank you Ray, Pipeclay, and Dave I have taken all on board, I now have a much clearer understanding and behaviour of a small working mill, I shall now proceed and gain the practical hands on experience that only time and practice can give, with of course some more questions and hopefully answers from you gents and maybe others.

In the coming months I will purchase a coolant system and a bit later a suitable power feed unit this brings up other questions as to the best options to go down and price.

I have had a look at H&F and there is some gear there, AL-99SP Power Feed Unit X-Axis (110V) transformer required for this unit, and a CPP-20LT Coolant Pump & Tank (240V) Plastic Tank

The power feed unit is rather expensive there may be other options available maybe I could make my own, early days on this one, you folks may have some input on things on which way is the best to go. The difficult thing would be getting all the right components together DC motor reversing switch and a speed control. The coolant pump is an easier option but by the time I got all the parts together it may be cheaper to purchase from H&R in hindsight I should have got the next model the story of my life excluding my wife 42 yrs. married

excluding my wife 42 yrs. married

Col May your saw stay sharp and your nails never bend

May your saw stay sharp and your nails never bend

-

12th March 2012, 03:05 PM #15Dave J Guest

The power feeds can be bought from the US for around $500 posted, and there is a Taiwanese supplier on ebay. Someone on here bought one last year and I never heard any complaints.

I have also seen the standard type like mine mounted on mill drills, but you will have to make up an adapter. These can be bought for around $300 posted.

I had to adapted both the Y and Z power feeds on mine because they are only suited for the Bridgeport mills, but once you see how they operate there is not much to them.

Dave

Similar Threads

-

Arboga EM825 mill vs Hercus model 0 mill?

By neksmerj in forum METALWORK FORUMReplies: 23Last Post: 14th May 2011, 03:16 PM -

What size/shape cutters do you use on your mill?

By markjaffa in forum METALWORK FORUMReplies: 9Last Post: 6th July 2010, 01:52 PM -

carbide end mill cutters

By eggo in forum CNC MachinesReplies: 5Last Post: 7th October 2009, 01:08 AM -

No. 0 Mill Serial Number and Mill at Work Photos

By Anorak Bob in forum THE HERCUS AREAReplies: 1Last Post: 30th December 2008, 03:31 AM -

Comparison Between C.S Mill & Bandsaw Mill

By echnidna in forum SMALL TIMBER MILLINGReplies: 2Last Post: 7th October 2007, 04:26 PM