Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 12 of 12

Thread: Parting/cutting on the shaper

-

25th July 2012, 11:48 PM #1

Parting/cutting on the shaper

Parting/cutting on the shaper

Hi,

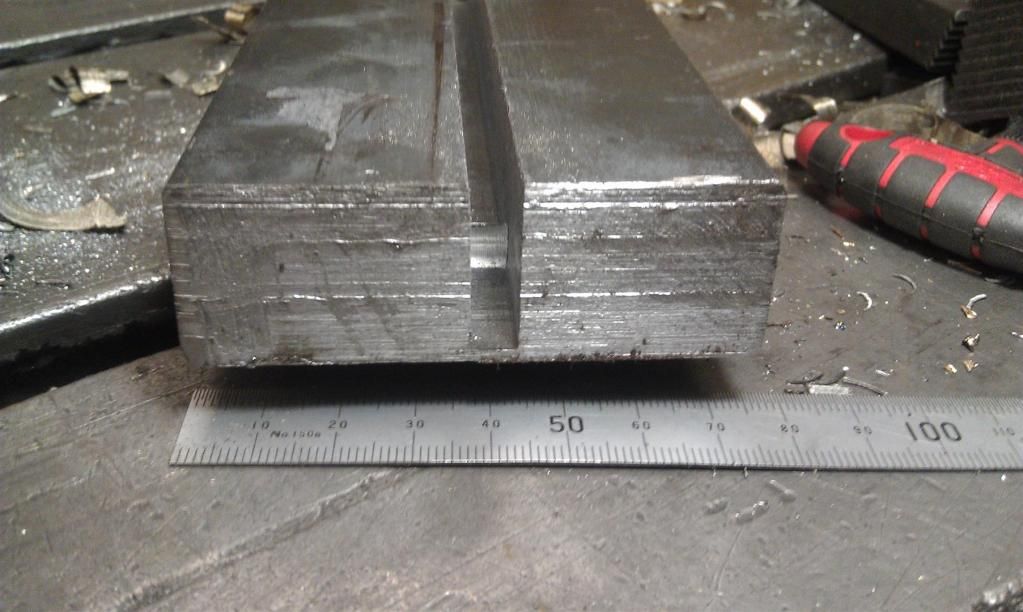

I started a little project tonight, just some decent t nuts for the shaper.

The steel i am using is the offcut from the vice jaws, but it is a bit wide.....so i thought i would cut it in 2 with the shaper (i still don't have a bandsaw -and here am i bidding on a surface grinder )

)

I sharpened the parting tool as you would for the lathe but the chatter was unbearable.... I then tried to v the top of the tool.....still bad.....round nose? great until the whole cutter was cutting. I even reversed the tool and locked the clapper...better but still not good. I ended up going back to square but with a lot more back rake. Cuts pretty well but i had to hold the toolpost down otherwise i was getting chatter at the start of the cut. In the finish the piece was pushed out of the clamps before i got through it but there is not much left to run the grinder through. In the end it probably would have been quicker to cut it with a hacksaw but i learned a lot....

but there is not much left to run the grinder through. In the end it probably would have been quicker to cut it with a hacksaw but i learned a lot....

[ame=http://www.youtube.com/watch?v=SWOSaHIO2WA]24" Queen City shape parting tool - YouTube[/ame]

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

25th July 2012 11:48 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

26th July 2012, 12:05 AM #2

Senior Member

Senior Member

- Join Date

- Jun 2012

- Location

- Germany, Outback of Munich

- Posts

- 213

I also once (had) to do that. Is was quite exciting.

I used a HSS part off blade and LOTS of cutting oil.

Nick

-

26th July 2012, 12:07 AM #3

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Would take you awhile to get through it on a surface grinder.

Have you thought about making a hacksaw frame up for it?(you shouldnt have any trouble finding a vid on utube)

Stuart

-

26th July 2012, 08:52 AM #4

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- South East Queensland, Australia

- Posts

- 354

Hi Ueee,

It's lookin good.

It's lookin good.

I'd lock the clapper, set stroke position to give more room at the beginning of the stroke to give enough time to do the downfeed adjustment. Try a tool with not much bottom clearance(lathe terminology , front clearance).

Some cutting oil(or even just engine oil), or soluble oil in a squirt bottle should help too.

Good luck with the tee nuts.

Cheers.If I'm not right, then I'm wrong, I'll just go bend some more bananas

.

.

-

26th July 2012, 10:14 AM #5

Distracted Member

Distracted Member

- Join Date

- May 2010

- Location

- Lower Lakes SA

- Age

- 58

- Posts

- 2,557

I haven't parted per se, but have done some slotting. Most of the problems are similar to parting on a lathe but there's an extra one. Because you're feeding with gravity the backlash is always trying to bite you, a bit like climb milling I guess. All you can do is adjust it out as much as possible and keep the gib snug.

I find my auto down feed is too coarse for slotting. I need to hand feed the finest amount: .02 - .05mm. You can't be in a hurry. My technique is to apply some preload to the handle on the backstroke and when the clapper seats it will bump it around.

As Log says, front clearance can be small and that should help support the tool. I don't know what the minimum is, maybe 2 or 3 deg? I've fooled around with edge geometry but the biggest improvements have come from a narrower tool. Every time I grind it it gets narrower and better. Will check later but the one I've been using is maybe around 3 or 4 mm. I know 1/4" doesn't sound big, especially for a machine like yours, but it's big for parting. Imagine using it on a lathe!

Edit: Stu is right: Saw it if possible. Come to think of it I've seen a pic recently of a short piece of saw blade mounted in a shaper tool. Will see if I can find it.

Here: http://bbs.homeshopmachinist.net/thr...558#post783558. Ok it's not going to help for parting unless it's very thin work. Still could be handy though.

-

26th July 2012, 03:32 PM #6

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

I have a goose neck tool for my Hercus lathe's lantern toolpost.

I tried it on my Douglas shaper. It works great! All chatter ceased - smooth as silk.

Jordan

-

26th July 2012, 10:23 PM #7

Thanks Guys,

Lets see.....I didn't even think to add oil....was caught up in the moment i think....

I had such a short run up on the cut so the speed wasn't too high at the start of the cut. I had the gib done up firm so i had to push the toolhead down and not have it fall. I have almost all the backlash out of the fixed end of the screw but the nut has about 10 thou.

My grinding angles are about 15 deg bottom (didn't think it was so big) and 10 on the front (top for the lathe). I have been looking online for a cheap enough 1/8" thick blade, but once you get up into this size they are pretty few and far between.

I didn't think the chatter was too bad....but today i noticed the 2 wedges under the machine where out....and then it dawned on me the whole 2+tons of her had moved back a good inch or more

Thanks for the link Bryan, that does look handy.

As much as making a saw frame would be handy, it would give me an excuse not to buy a bandsaw, and also use the shaper a lot for work that another machine would be better at.

I bought the parting tool as i have a large piece (like 1500x500) of 35mm plate. There are a few things i would like to do with some of it but every time i think of them cutting the plate puts me off. I had to cut some years ago for a job, all i had was the 5" grinder....even with 1mm wheels it took forever......1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

27th July 2012, 12:58 AM #8

Senior Member

Senior Member

- Join Date

- Jun 2012

- Location

- Germany, Outback of Munich

- Posts

- 213

The problem with the part off tool is, that the clapper box makes a mess on the back stroke. On the back stroke, the blade rubs in the slot and is (violently) pulled out. Way more than with a "normal" cutter. The clapper box can't handle that much stroke properly.I had the gib done up firm so i had to push the toolhead down and not have it fall. I have almost all the backlash out of the fixed end of the screw but the nut has about 10 thou.

The problem with the part off tool is, that the clapper box makes a mess on the back stroke. On the back stroke, the blade rubs in the slot and is (violently) pulled out. Way more than with a "normal" cutter. The clapper box can't handle that much stroke properly.I had the gib done up firm so i had to push the toolhead down and not have it fall. I have almost all the backlash out of the fixed end of the screw but the nut has about 10 thou.

That's the same problem as with cutting keyways on the shaper. Here, it's advisable to completely block the clapper box.

Nick

-

27th July 2012, 02:19 AM #9

4-6-4

4-6-4

- Join Date

- Mar 2009

- Location

- Melbourne

- Posts

- 295

Parting off

Parting off

Greetings Chaps Instead of a surface grinder you should invest in one of those Taiwanese metal cutting Band saws. I never cut anything over 1/4 inch Dia with a hack saw. I had to re motor mine recently but it goes OK.. I have had two now and this one actually cuts square. With a bit of drama and time I have cut 6 inch Dia steel. They will take 6 by 4 rectangular steel I have cut 3/4 inch plate on mine in the vertical mode. To do this you sit on the vice and using a piece of wood between the job and you stomach your hands guide the metal. And they are cheap. yours 4-6-4

-

27th July 2012, 09:34 AM #10

Mechanical Butcher

Mechanical Butcher

- Join Date

- Oct 2004

- Location

- Southern Highlands NSW

- Posts

- 920

-

27th July 2012, 01:22 PM #11

Senior Member

Senior Member

- Join Date

- Jan 2009

- Location

- Captains Flat

- Age

- 71

- Posts

- 131

gooseneck

gooseneck

I saw someone refer to using a gooseneck on shaper. I too use a wacking great Armstrong gooseneck that I bought on ebay thinking it was half the size. I ground down the top of the gooseneck little by little to increase the "spring" until chatter ceased. Cuts very smoothly. I sharpen cutter at 90 degrees, pretty much same as I would for parting on the lathe. I also have a beautiful little (american) gooseneck that I use to part-off on the Hercus and that too works nicely on shaper.

David

-

27th July 2012, 01:30 PM #12

I don't own any gooseneck holders. This is the one I am using, https://www.woodworkforums.com/f65/to...ml#post1523154

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

Similar Threads

-

Parting for beginners

By sjm in forum WOODTURNING - GENERALReplies: 12Last Post: 23rd February 2011, 06:39 AM -

Parting off on Hercus

By YarrD in forum THE HERCUS AREAReplies: 7Last Post: 21st November 2009, 09:48 AM -

Two for $1.00 Parting Tools

By Paul39 in forum WOODTURNING - GENERALReplies: 5Last Post: 23rd May 2009, 06:03 AM -

Parting off video

By .RC. in forum METALWORK FORUMReplies: 4Last Post: 6th August 2008, 04:03 PM -

Parting off problem

By Sterob in forum METALWORK FORUMReplies: 20Last Post: 27th May 2007, 06:21 PM