Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 75 of 132

Thread: Cylindrical Square

-

20th July 2011, 09:00 PM #61

Hi Pete,

If your lathe turns a taper, then the tilt has to be made greater than the taper.

Regards

Ray

-

20th July 2011 09:00 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

20th July 2011, 10:25 PM #62

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Ray, assume the base has a 10 degree "tilt" and the taper is 5 degrees. Put the indicator on the cylinder and rotate it to the maximim reading on the dti. At that point the surface contacting the dti will be sloping toward the dti minus 5 degrees (with reference to the plate it's standing on). Now rotate the cylinder as you described until the dti reads the minimum reading, the cylinder will be sloping away from the dti at the point of contact 15 degrees. Find the mid point as you described in your note. That point will be sloping away from the dti at 5 degrees, ie the amount of taper only. If the cylinder has no taper (as measured with a micrometer etc) then at that point (and assuming the cylinder is perfectly round, so will its mate diametrically opposite), the cylinder surface will be perpendicular to the surface it's standing on. If it has a taper it will be the taper angle.

Pete

-

20th July 2011, 10:46 PM #63

Hi Pete,

Yes, I see your point. In general, with a non-tapered tilted cylinder the edge will swing above and below 90 degrees equal amounts, when the cylinder is tapered, the 90 degree point moves towards the point of maximal tilt as the amount of taper increases, in the limiting case the 90 degree point is also the point of maximal tilt.

Regards

Ray

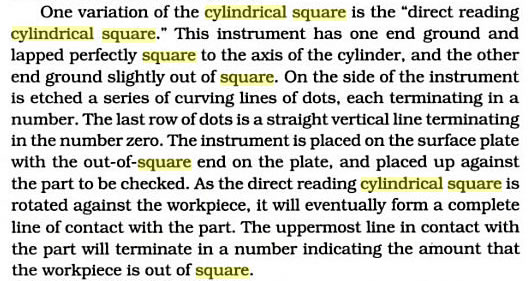

PS I've discovered you can actually buy specially tilted cylindrical squares, that are marked around the circumference for calibrating squares.

This book calls them "Direct Reading Cylindrical Squares"

-

20th July 2011, 11:10 PM #64

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Precisely. That's why you first need to determine that the cylinder has no taper. However that's very easy to do by simply using a micrometer, although there are other methods that are arguably more accurate, I think it's accurate enough for home shop purposes. Once that's done, then use your method to determine the point that's perpendicular. The only thing I've suggested in the past however is to locate the cylinder in some form of V. If held against a flat surface no matter how hard you try not to shift it along that surface as you rotate it, this is pretty fine work we're talking about, and it will fractionally move. Then you're faced with sliding the cylinder up and down slightly to confirm the maximum and minimim points ... a PIA I reckon I'd rather avoid.

Yes I've heard about those squares, but to be honest I've never seen one. Speaking of which, I'm trying to buy some things from the company you bought yours from, they better go nameless as it feels like trying to pull teeth! They're not exactly helping me with the buying process!! In the end I decided to go for a granite square instead of the cylindrical one.

Pete

-

20th July 2011, 11:54 PM #65

Hi Pete,

This is a repeat of what I posted earlier in this thread, you must have missed it. The notch is just visible at the base of the cylinder. Also you can see the relevant marks on the top of the cylinder.

Rotating against a 0.001mm indicator to find the high and low spots, and watching how the needle moves to see that there are no bumps or dips, I found that it was pretty well essential that the indicator be mounted on a base that registered against the cylinder, there is a notch that locates the cylinder. Dust is a major menace, but with a little patience and care you can find the highs and lows.

...........................................................

Regards

Ray

-

21st July 2011, 12:18 AM #66

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Thanks Ray, I'd seen that photo but hadn't noticed the notch until you pointed it out. I was just going off of the pdf notes you posted. Dust is amazing isn't it, it seems like surface plates have an inbuilt dust magnet and things you would even notice suddenly feel as if you're working in a gravel pit!

Pete

-

7th November 2011, 09:14 AM #67

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

Make a small cylindrical square last night/yesterday afternoon..

Have not checked it for squareness yet but it should be not too bad...

Some pictures showing it.... I drilled a hole full length through it and tapped 8mm both ends... The photo showing the micrometers is from either end... But take the measurement with a grain of salt, as once you get into those sorts of dimensions it gets very hard to measure consistently... Measured it up and the needle says 0.0001" taper total error... So I shall now go and gloat on HSM how my workshop grade lathe is good for 50 millionth's squareness and that paying extra for the likes of a Monarch 10EE is wasted money...

Light red, the colour of choice for the discerning man.

Light red, the colour of choice for the discerning man.

-

7th November 2011, 11:52 AM #68

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi RC,

It certainly looks good. Is that straight off the tool or was there some lapping done?

I almost asked what diameter bar you used

About 100mm long?

What was the rule again "no more than 2.5 times dia"?

Stuart

-

7th November 2011, 02:19 PM #69

Hi .RC,

2 micron taper error, not too shabby, who needs a cylindrical grinder..

Even if the base isn't square with the sides, there should be at least 2 points on the diameter where it is exactly square. I'm interested to see how goes when you rotate it.

What's the accuracy of that Tesa level square like?

Regards

Ray

-

8th November 2011, 05:49 AM #70

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Hi Richard

Is there a reason your centre is in the 3 jaw and not in the headstock spindle? Also did you have to do any adjustments to the tailstock to get that kind of accuracy? Just want to know for when I give one a go.

Phil

-

8th November 2011, 06:57 AM #71

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

I put it in the three jaw and turned the centre from there as it takes out one more variable (the centre) in the process..

Reading old turning books, when turning between centres and using a centre in the headstock the first part after installing the centre was to turn/grind it to true it up...I did not wish to do that to one of my centres...Light red, the colour of choice for the discerning man.

-

9th November 2011, 11:51 AM #72

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Richard, can you run that one past me again, I didn't follow that. By "it", did you mean you turned up a new centre by simply chucking some stock in the 3 jaw and turning a taper on it? That would certainly make sense if you did and what you said you were trying to achieve. FWIW I have found all my cheapie Chinese centres have been accurate as received, but I guess like a lot of Chinese stuff that would be purely the luck of the draw. My new lathe is unfortunately MT4 taper (well actually that's obviously good, but needs much new tooling), so I guess I get to play lotto all over again. I'll try an MT4-MT3 adaptor, to get me out of strife, but don't see that as a good long term solution where real accuracy is required.

Nice job on the square by the way. I'll also turn one on the new lathe as part of checking its accuracy once it's installed and levelled.

Pete

-

9th November 2011, 12:04 PM #73

GOLD MEMBER

GOLD MEMBER

- Join Date

- Mar 2011

- Location

- Dural NSW

- Age

- 82

- Posts

- 1,120

-

9th November 2011, 12:22 PM #74

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Oh yes sorry Bruce, things have been just stupidly busy lately. Thank goodness for Skype video or my kids would forget what I looked like, the dog already seems uncertain when I get home each time!

I will also put up a thread or two on the adventures of the lathe. Without getting this thread OT, it's a brand new Hercus 260, a bit "shop soiled" but otherwise hasn't ever turned metal and is still covered in cosmoline. Perhaps that in itself is of interest to a few members in the Hercus section. The other thing I'll put up is the precise procedure I went through re-importing it back from Hong Kong to home for those considering importing machines directly. It all went extremely smoothly until it hit Oz. As I said to GregQ, $730 to crate and ship from dealer in Hong Kong, a 1/4 way around the world to the docks in Sydney. To get it another 100 m from the wharf to the back of my ute cost me around another $1K, so I wasn't impressed with that! The full story when I get a chance to sit down and add up the total charges.

Pete

-

9th November 2011, 02:15 PM #75

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2011

- Location

- Australia east coast

- Age

- 71

- Posts

- 1,469

I can't say I'm surprised by the local charges. It's all a mystery but you pay for it.

WRT centres in the 3 jaw, all you do is chuck up a piece of round stock, preferably with a shoulder so it can't slip backwards, then do a skim cut on it to get the point running true. No need for it to be hardened or whatever as it rotates with the workpiece, you just want the point concentric to within the limits of the lathe. Doing it like this is easy and it doesn't matter how far out (within reason) the 3 jaw is, because you don't remove the centre until you've finished.

I've got a reducing bush & hard centre for my Chipmaster but I've never used them in the entire time I've owned that lathe.

Did you get that pic of my Emco Maximat 11 I sent?

PDW

Similar Threads

-

Cylindrical cabinet

By 3 toed sloth in forum WOODWORK - GENERALReplies: 19Last Post: 2nd January 2009, 02:35 PM -

Cutting cylindrical holes.

By Timmm in forum WOODWORK - GENERALReplies: 11Last Post: 6th July 2007, 07:32 AM -

Make your own cylindrical sander

By rsser in forum WOODTURNING - GENERALReplies: 15Last Post: 27th August 2006, 09:59 PM -

Making a round / cylindrical box

By samueolchoo in forum WOODWORK - GENERALReplies: 2Last Post: 29th April 2003, 10:14 AM