Thanks: 0

Thanks: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 41

-

7th April 2013, 08:36 AM #16

What a great set of WIP posts Dave

.

.

Thanks for posting that, great pics as well.

-

7th April 2013 08:36 AM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

7th April 2013, 10:27 AM #17

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2011

- Location

- sydney

- Posts

- 880

Hi Dave,

Great work. Really good pictorial essay as well. Good to see your back.

Ben.

-

7th April 2013, 10:49 AM #18

amazing and interesting to a new comer

-

7th April 2013, 10:51 AM #19

Dave thanks so much for the WIP shots. You have made me envious. You can now take on a complex job with lots of tool changing and be head of the pack with all those holders.

A comment from the "sideline", the Dickson system may be "complex", when compared to other systems, but that ability to get the tool to centre height by the knurled knob puts it slightly ahead. It may have been a repetitious job but now that its all done and looking so good it was well and truly worth it. How many hours approximately did it take?

Great job indeed and yes you are an asset to the Forum and the rest of us less experienced can marvel at your abilityJust do it!

Kind regards Rod

-

7th April 2013, 10:55 AM #20

Nice crisp knurling too! Any additional pictures of the clamp knurler?

Regards

Ray

-

7th April 2013, 01:05 PM #21Dave J Guest

Thanks Guys, makes it worth posting if at least a few get something out of it.

Rob, wow thans for the compliments, good to be back.

Hi Ray,

Here is the knurler in detail, there is one picture I took through an eye loup.

https://www.woodworkforums.com/f65/scissor-knurl-153449/

Dave

-

7th April 2013, 01:48 PM #22

Thanks Dave, I wondered why I missed that, I think I was away around that time. Just another question, have you considered case hardening them? I have some "cherry red" if you wanted to give it a try.

Regards

Ray

-

7th April 2013, 01:57 PM #23Dave J Guest

I was thinking about it and would like to, but with all the machining they would relax and warp I think.

I have them where they all lock up as the factory, so if they where to warp I am stuffed because I cant take any more off the V's and will be left with a bunch of steel blocks good for nothing.

Saying that the lock has a long way to go until they wouldn't fit, maybe they where designed to allow for wear. On the factory tool holders and tool post it would be not be in my life time as they are really hardened.

Dave

-

8th April 2013, 09:37 AM #24

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Jun 2011

- Location

- Australia east coast

- Age

- 71

- Posts

- 1,469

I wouldn't worry about hardening them. You'd have to remove & replace them a hell of a lot of times before you wore the mating surfaces to the point of measurable problems.

Making a pile of these has been on my 'round tuit' job list for ages, though I'll probably do mine on the horizontal mill as I have all the cutters I need. The undercut is about the only operation I'd need to do differently. As someone else has commented I think I'll do an entire length of bar (there's one sitting on the floor) and then cut off slices to suit. You can't have too many tool holders really.

Someone in the UK has recently listed some 00 sizes for a reasonable price but I don't know if my tool post is an 00 size or not.

WRT accuracy some years ago I was doing a short production run swapping tools out. The repeatability was better than 0.001" for sure as, once I had the cross slide DOC set, I could turn, face & bore for bearing recesses without really bothering to check for final fit.

PDW

-

8th April 2013, 12:48 PM #25Dave J Guest

Thanks for the replies,

I thought long and hard about heat treating them before I started and decided against it because of them warping.

They are only mild steel so no chance of doing it at home with low heat. John Stevenson did suggest Tuftriding them, but even if they where $10 each to get done (highly unlikely here) that would be $460 so sort of kills the cheap part of making them.

If they where drooped on the floor the V is protected as it's recessed in and so is the T slot, so it would only be cosmetic damage.

As for wear I have been using a few and they don't seem to be wearing. The only part that could really wear is the T slot where the plunger pulls them in,you would never have enough force to squash the V's and it would take a lot of use to wear they as they don't slide.

Dave

-

8th April 2013, 12:52 PM #26Dave J Guest

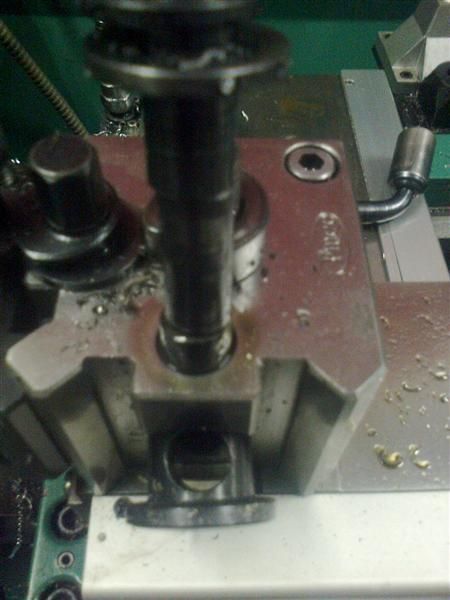

Here are some detailed shots of how the tool post works for those that are not familiar with them. I think it simpler than the wedge style and also think the tool holders are easier to make than the dovetail ones.

It would not be hard to make up a tool post in the home work shop.

Sorry about the crappy pictures they are off my phone.

Dave

-

8th April 2013, 08:50 PM #27

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Dave,

You think 46 will do? Still better ten to many than one to few.

Still better ten to many than one to few.

Great work.

Re hardening I wonder if 46+ soft holders would wear the hardened post out first anyway?

Stuart

-

8th April 2013, 09:55 PM #28

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2006

- Location

- Mallacoota,VIC,Australia

- Age

- 53

- Posts

- 656

HI

Dave,

Dave,

Wow Mass Production. Gee Dave 230 M8 Holes tapped by Hand how are Your Wrists ?. The Tool Holders look great, I really like the Black Finish on the Knobs. I haven't had a go at Blackening anything in Oil yet, how Hot like Colour wise do You have to get the Metal to get a Finish like that ?.

Dave You certainly are an Inspiration to us all and as Steamwhisperer said an 'Asset' to this Forum - Well Done

.

All The Best

.

All The Best steran50 Stewart

steran50 Stewart

The shortest way to do many things is to do only one thing at once.

-

8th April 2013, 10:17 PM #29Dave J Guest

Stuart thanks, your probably right about the wear, LOL

Steran (Stuart), thanks for the compliment.

I did promise this thread last year but with things going on in my life it got delayed so I went to the extra trouble to do a good post about the process with lots of pictures.

With the blackening if the part it not critical (warping) like the adjusters I get them just orange/red hot and dunk them, take them out and reheat them again which seems to bake on the black and re dunk them and hang them to cool.

After that just wipe them with a rag to clean it off, works great.

I usually use used motor oil but with those I was given so filthy diesel oil from a truck to try, it might be just my thinking but it seems to blacken them better.

I use either my propane burner or my cheap clip on butane burner to heat them. The butane ones clip onto the camping throw away cylinders you buy in packs of 5 from the supermarket. I picked up 3 at the markets for $10 each and they have a built in igniter, very handy to have around.

Dave

-

9th April 2013, 12:20 PM #30

If you got carried away with the quantity would you be wiling to part with a few?

Also did you make the internal parts for the block? Ie the cam pin, pad and spring? My Dixon only has one operational side and original Dixon parts are horrendously expensive..

Similar Threads

-

quick change tool post help

By Aerohydro in forum METALWORK FORUMReplies: 5Last Post: 23rd April 2012, 12:11 AM -

quick change tool post

By scratchbuilt in forum METALWORK FORUMReplies: 18Last Post: 13th March 2012, 07:46 PM -

Quick Change Tool Post

By tinkera in forum METALWORK FORUMReplies: 3Last Post: 22nd September 2010, 11:17 AM -

Best Way To Modify Quick Change Tool Post

By Retromilling in forum METALWORK FORUMReplies: 32Last Post: 30th April 2009, 06:10 PM -

Lathe owners Quick Change Tool Post Sets

By Penpal in forum METALWORK FORUMReplies: 14Last Post: 17th June 2008, 09:02 PM

Members who have read this thread: 0

Members who have read this thread: 0

There are no members to list at the moment.

Likes:

Likes: