Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 1 to 13 of 13

Thread: HAFCO Cutting/Coolant Fluid

-

24th April 2010, 05:41 PM #1

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

HAFCO Cutting/Coolant Fluid

HAFCO Cutting/Coolant Fluid

Hi Guys ,

has anyone on here used the Hare and Forbes Coolant/ Cutting Fluid ?

https://www.machineryhouse.com.au/Pr...stockCode=S091

How did you find it ? and is the 20:1 ratio with water ok or is it better being 10:1 ?

It says it High resistance to microbial degradation, no rancidity is this correct or does it get a bit whiffy after awhile ?

Thanks ,

Plushy

-

24th April 2010 05:41 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

24th April 2010, 06:38 PM #2Dave J Guest

Hi,

I haven't tried this new stuff. I am still going off the old stuff I have, it goes off if I don't keep it airated.

The mix ratio on the old one states

General purpose 20 to 1

Milling drilling taping 10 to 1

Cast iron 25 to 1

Dave

-

24th April 2010, 06:43 PM #3

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

If you are only a hobbyist, why do you want soluble oil??? Just use neat oil...

-

24th April 2010, 08:56 PM #4

GOLD MEMBER

GOLD MEMBER

- Join Date

- Oct 2002

- Location

- NSW

- Posts

- 1,610

-

24th April 2010, 09:51 PM #5Dave J Guest

Fixed it up.

Just seeing if you were taking notice to the ratio's.

Dave

-

25th April 2010, 11:23 AM #6

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

I got some Caltex Trusol Ep...very similar stuff...may be the same who knows as HF is only packaged for them, from Adelaide Fuel Distrubutors (interstate would have similar distributor outlets - Ring Caltex head office for your local distributor)

20litre drum cost $117.00 inc GST.... yes thats one hundred and seventeen dollars

Trusol also needs to be mixed at similar ratios, and as I understand it, the trick is to mix it so it still feels oily on the hand ...that way you dont suffer corrosion problems.

-

25th April 2010, 11:37 PM #7

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

Thanks for the Replies Guys

I will give it a go using the recommended ratio`s and let you know what i think . I have a few pieces to make out of steel and aluminium so i will let you know how it goes .

R.C if i can afford to buy a better product and it gives a better cut then why not ?

The Ward 3DS lathe that i have has a inbuilt Coolant system so i figured i would use it . If it turns out to be not that much of a difference then i will chalk it up to life experience .

. If it turns out to be not that much of a difference then i will chalk it up to life experience .

-

26th April 2010, 07:09 AM #8

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

I was actually more concerned about corrosion problems by using soluble oil on a machine that may not see constant use..

-

26th April 2010, 10:39 PM #9

Senior Member

Senior Member

- Join Date

- Sep 2007

- Location

- Newcastle NSW

- Age

- 77

- Posts

- 155

I second RC's advice.

Where I worked I had a beaut lathe (Emco Maximat V13) but the saddle ran very close to the tailstock slide way and soluble oil would get trapped under the saddle and would cause corrosion on the way if it was not removed promptly. I used to slide sheets of paper towell under the saddle to soak up the coolant. Even so the slideways became stained from the coolant.

On my home lathe I only use motor oil to assist cutting and have been satisfied with the results but then again I dont work the machine too hard.

I have a soluble oil tank and pump system for the lathe and will use it if I need to but so far the motor oil has done the job. The cheapest oil would be suitable. I tried Mobil 1 which I drained from my motorbike after 5000Kms. but it was a little too dark .

Russell

-

27th April 2010, 02:03 AM #10

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

Thanks for the Heads up R.C , i will keep an eye out on the corrosion . I give the Lathe a good clean up after every use and a light spray with a light weight oil .

I also tend to take heavy cuts so i am hoping that the coolant will help make the cutting tools last longer i tend to be a little impatient

-

27th April 2010, 02:33 AM #11

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jun 2007

- Location

- sydney

- Age

- 64

- Posts

- 3,566

If you are useing your tooling to its limits and the machine is not strugling for power there is no problem.If you are taking cuts that are making the lathe labor or your tooling is wearing or dulling quickly you may have to adjust your technique.

The cutting oil with give you to benefits somewhat with tool wear more so if its HSS and more so for cooling.

-

5th May 2010, 02:53 PM #12

New Member

New Member

- Join Date

- Apr 2010

- Location

- Moormbool West

- Age

- 74

- Posts

- 7

h&f soluble oil

h&f soluble oil

Hi.It works good but it evaporates at an alarming rate

-

7th May 2010, 01:51 PM #13

Member

Member

- Join Date

- May 2007

- Location

- Ballarat,victoria

- Posts

- 82

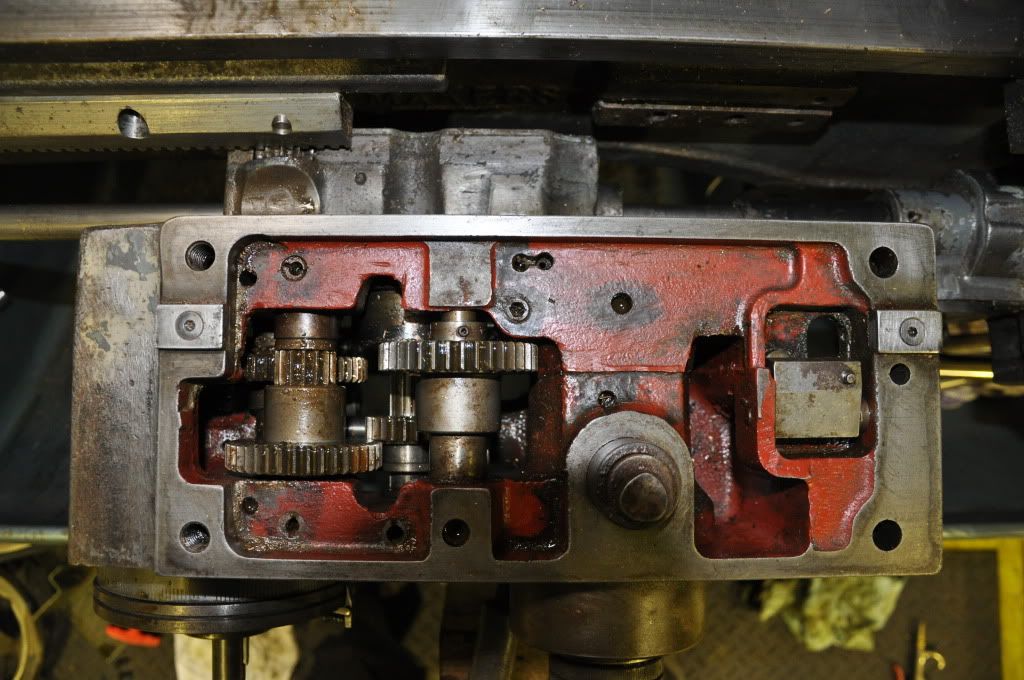

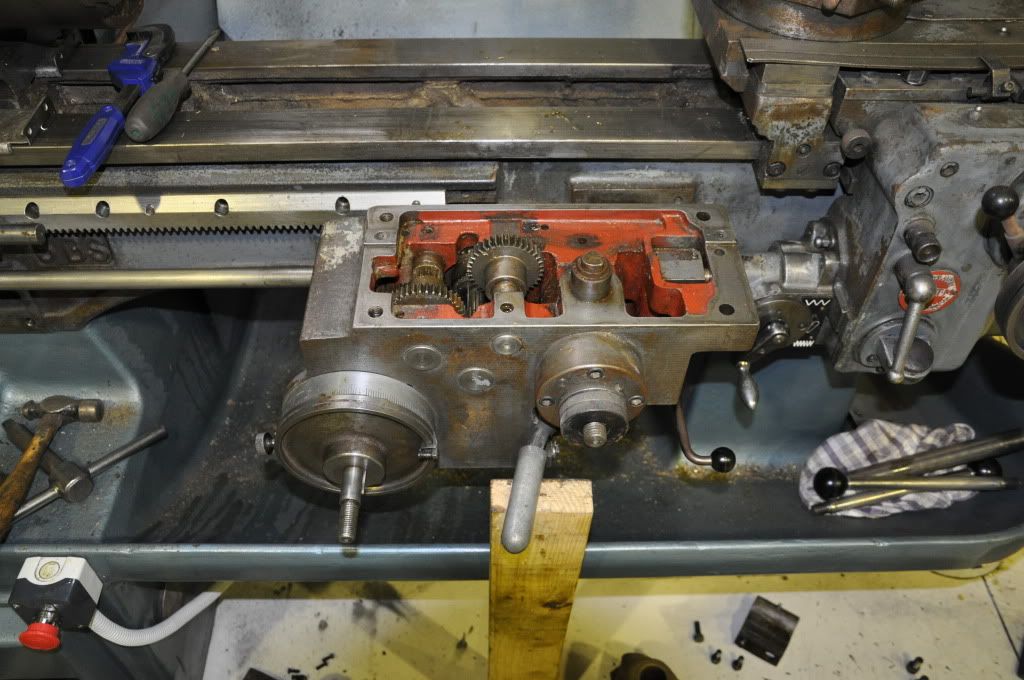

Thanks for all the advice Guys , the coolant setup is on hold at the moment as i am pulling the apron apart to change out the pinion for a new one .

just gotta work out how to take out the feedshaft from the change box

Similar Threads

-

Layout Fluid

By m2c1Iw in forum METALWORK FORUMReplies: 25Last Post: 3rd January 2013, 01:49 AM -

which coolant ?

By Oldhack in forum METALWORK FORUMReplies: 16Last Post: 1st October 2009, 08:06 AM -

Hafco AL-336 Metal Lathe Cutting Imp Threads

By steran50 in forum METALWORK FORUMReplies: 17Last Post: 1st September 2009, 10:18 PM -

Coolant/lubrication

By Tiger in forum METALWORK FORUMReplies: 3Last Post: 7th December 2005, 08:04 PM -

Cleaning Up Auto Trans Fluid on Driveway

By rodm in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 6Last Post: 30th November 2003, 11:51 PM