Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 121 to 135 of 196

Thread: All hail the shaper gods!!

-

17th May 2012, 11:59 PM #121

Help!

Help!

Hi,

Well, i seem to have hit a small problem.....

I pulled the motor and gearbox out of there frame today. I already new the gearbox was leaking, but couldn't tell where from. It turns out that both the input and output shaft seals are in need of replacing, and there is also a leak from either end of the unused reverse gear shaft. The reverse is no problem, i can just use some RTV as it will never turn. I also got the input shaft out no worries. The seals are above the oil level, and they are just felt wadding. The problem came when i tackled the output side of the box.

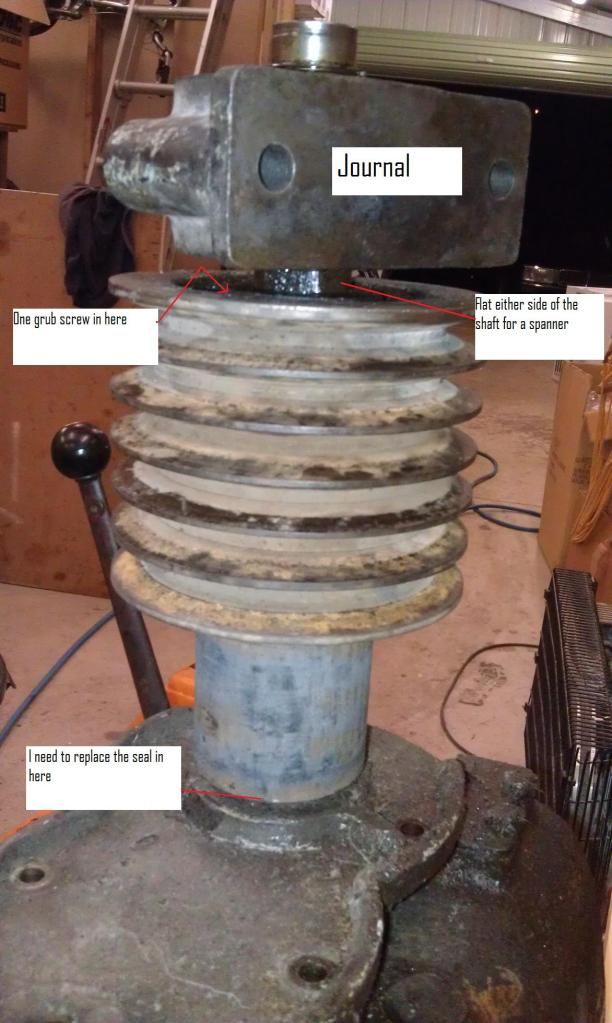

The output pulley is 6 belts wide, so it has a journal at the end for support. However i cannot seem to remove the journal or the pulley.

I think the journal is stuck simply because i can't get the bearing out, and the bush the bearing is on must be grub screwed onto the shaft (the bush is threaded to take a large nut to hold the whole lot together)

I tried a gear puller on the pulley itself, plus some heat, but it won't move either. there is only one grub i can find...its actually a square headed bold so i don't think its another double grub problem. Any suggestions?

A pic may help:

I really need the pulley off so i can get the cover plate off and get to the seal.

The other thing is, what would be a good replacement for the felt? More felt?

The box has a few numbers on it but no manufacturers marks.

Ewan

-

17th May 2012 11:59 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

18th May 2012, 08:18 AM #122

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Hi Ewan,

it sounds to me like the outrigger journal bearing has a tapered bore and the sleeve is tapered to match. The nut pulls the two tapers together. The sleeve should have a split in it along its length. Loosen the nut and knock the sleeve back or the bearing forward towards the end of the shaft (preferred) and that should loosen the sleeve and bearing from the shaft.

Thats what it sounds like. Of course I could be wrong .

.

Phil

-

18th May 2012, 09:19 AM #123

Thanks Phil,

Yes the sleeve is split, i'll have to knock the sleeve back as i can't get to the other side of the bearing. I'll try that and see how i go.

Ewan

-

19th May 2012, 01:17 AM #124

Thanks again Phil,

You where right, the bearing ID is tapered. Next problem is i need a new bearing as the outer race was either already cracked or got cracked in the process of removal. Its a FAG bearing, tandem ball, the races are just slightly concave. It has inner and outer race numbers (like P208 and P507 or similar) but no other numbers. I hope i can find a replacement without going to the cost of replacing the sleeve etc.

Now for the pulley....

Ewan

-

19th May 2012, 08:18 AM #125

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Sep 2011

- Location

- Ballarat

- Age

- 65

- Posts

- 2,659

Well done Ewan,

the fun part is putting the new one back on. They can be a little tricky. With regard to availability, the hard part will be putting up with the looks when you ask for an imperial bearing size (assuming it's imperial). I get them all the time for line shafting at work. I find it better to get a new sleeve as well. The square headed bolt you mention is called a 'Hard Point' and I have seen grubscrews under these as well so "check check and double check". Also make sure there are no other hard points or grub screws at different points on the pulley. It's amazing how much pressure one small grub screw will hold, that is of course until you start running the pulley and for some reason they just come loose, hence the second grubscrew as a lock nut.

Remember, "check check and double check"

Good luck.

Phil

-

22nd May 2012, 08:34 PM #126

The bearing is metric! I don't know when the box was put on the machine, whether it was run off a line shaft for some time then changed over, or it came with the box, and the journal was replaced later. The box has imperial gears and shafts. I did finds this stamping on the box, seems to me like a date, but i would have thought it too early for a box like this, but i don't really know, anyone like to take a guess? If it is a date, it would seem i have a rough build date for the machine.

Ewan

-

22nd May 2012, 08:47 PM #127

Hi,

I pulled everything else apart today, ready for one last dirty session with the angle grinder and wire wheel. I found a few more fixes, some babit bearings poured for the knee rise and fall shafts and a pretty nasty break in the casting that moves the crank end of the feed ratchet arm (does that make sense?) It has been repaired pretty well already.

I also found these strange diagonal scratch marks on some of the bearing surfaces...... i managed to get them to show up in a few pics

i managed to get them to show up in a few pics

I am lucky to not have to and i pray to the shaper gods that i never have to replace the cross feed screw or nut. It is a twin lead square, not ACME 1/2" pitch......

Ewan

-

22nd May 2012, 09:14 PM #128Dave J Guest

They might be the from the milling or scraping of the ways.

Dave

-

22nd May 2012, 09:20 PM #129

Yeah, they are scrape marks......it put a nice smile on my face when i found them

I don't know if they are original. By the looks of how much work she seems to have done i'd say not, but who knows......

The rise and fall screw is also telescopic like the one on your "new" horizontal mill

Ewan

-

22nd May 2012, 09:24 PM #130Dave J Guest

I would say it was rebuilt a time or 2 in it's life.

That mill is not new, I bought it a few years back but only found a few photos of it when I was looking for something else, so thought I would ask here what brand it was. I have another one as well that I have had for around 15 20 years, but it's only a little one.

You have got yourself in deep with this one.

Dave

-

22nd May 2012, 09:47 PM #131

Senior Member

Senior Member

- Join Date

- Dec 2011

- Location

- South East Queensland, Australia

- Posts

- 354

I'm sure the shaper Gods will be smiling

, seeing how it's coming along Ueee

, seeing how it's coming along Ueee

Forward ho, carry on and all that , eh what

, eh what

Cheers.If I'm not right, then I'm wrong, I'll just go bend some more bananas

.

.

-

28th May 2012, 10:53 PM #132

Getting there.....

Getting there.....

I'm getting there......this evening was pretty productive.

I found another 3 taper pins that needed replacing, so they are now done. I left the lathe as it was but gave myself more tool overhang and was able to use the tailstock for most of the cut. Next time i will cut them small end at the chuck though.

I have also painted the knee, inside the table and the table support.

Then i cut some oil grooves in the two bearings i made with the dremel and a cut off wheel.

I also pinched Blondies lead and tested the motor....two thumbs up from me

Hopefully i'll get the rest of the parts stripped tomorrow....without destroying another angle grinder!

a pin that needed replaced...not sure how that happened, its out of the cross feed shaft

mmmmm grey paint.....smell those fumes.....

bearings...

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

29th May 2012, 01:06 AM #133

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Apr 2012

- Location

- Healesville

- Posts

- 602

Ueee I'd like to lock you in my shed for a few weeks, maybe my shaper would see some progress then

-

31st May 2012, 02:26 AM #134

Done deal, now if you could explain to SWMBO......

Just a pic of the knee rise and fall i got together tonight. The gears seem to be cast iron, and the large one even has the machines serial # stamped in it, not the small one though, could be a remake, they both look like i'm not the first one to file them. I'll need to make a guard to stop any chips from getting into them, the gears were completely jammed with chips when i got her.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

1915 17"x50" LeBlond heavy duty Lathe, 24" Queen city shaper, 1970's G Vernier FV.3.TO Universal Mill, 1958 Blohm HFS 6 surface grinder, 1942 Rivett 715 Lathe, 14"x40" Antrac Lathe, Startrite H225 Bandsaw, 1949 Hercus Camelback Drill press, 1947 Holbrook C10 Lathe.

-

31st May 2012, 02:30 AM #135Dave J Guest

It really makes you wonder why they never cover the gears, I think just about every shaper cops chips in the knee gears.

Dave

Similar Threads

-

Gippsland, Gods own country one day, pretentious the next!

By AussieOzBorn in forum WOODWORKERS WITH DISABILITIESReplies: 8Last Post: 12th September 2012, 01:26 AM -

Hail storm

By PenTurner in forum WOODTURNING - PEN TURNINGReplies: 8Last Post: 10th March 2010, 03:49 AM -

just had some hail

By underfoot in forum NOTHING AT ALL TO DO WITH WOODWORKReplies: 5Last Post: 24th October 2008, 02:41 AM -

HAIL TRITONEERS

By DPB in forum TRITON / GMCReplies: 23Last Post: 12th December 2002, 05:41 PM