Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 121 to 135 of 138

Thread: Hardinge 5C Collet Brochure

-

18th January 2012, 03:30 PM #121

Hi BrianLara400*,

You make some good looking gear, well designed and solid. Nice finishing touches.

Just on the web page..

The Lightbox works fine on Firefox 9.01, but as others have noted there is a problem with the gallery navigation buttons. The web site looks good.

Regards

Ray

-

18th January 2012 03:30 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Age

- 2010

- Posts

- Many

-

20th January 2012, 08:45 PM #122

The website isnt entirely finished, hence why one portion appears in spanish - but there will be more content up soon.... So who's placing an order?

Bob, in liew of an actual brand on the light i'd have to conclude it probably is a sunnex or a very good forgery. The shroud etc looks exactly the same, and I couldnt find any markingd inside the base either.

Works well It would start to roast your hand if you left it there for more than about 3 secs.

I like the detachable head on yours, it would be a very handy feature at times..... who would win in a fight between your Crayley & your Sunnex?

-Imageshack has chosen to chage the orientation on these, just to annoy me- (how would I fix this?)

The trolley for your reference. The dividing head when in storage occupies the oposite side to the uni table. The hoist rated to 100kg

Picture of the vertical head lifting bracket for Greg's reference.

Picture of the vertical head lifting bracket for Greg's reference.

Is this an original handle on quill? I cant remember ever seeing what they were supposed to have? - I did see Bobs nice sensitive drilling attachment, I'd imagine I could build something similar for the riken.

This is a friends Southbend Nordic 15 that has lived in our shed for a while, currently in a 18month state of undress - just wondering if anyone knows of a good source of parts etc for these? (short of borrowing Rod Taylors time machine)

Precious little has ever been written about these, apparently southbend bought the design from a belgian/ french company Mondial, released it and then diss-owned it immediatley there after.

So anything related to these are notoriously hard to get? Has anyone ever had anything to do with them?

And a shot of it in use from a few years ago now binding a bat handle

-

20th January 2012, 09:28 PM #123

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

Photo Rotation

Photo Rotation

I was getting a sore neck.

-

20th January 2012, 09:35 PM #124

Brilliant... Thanks Bob

-

20th January 2012, 09:44 PM #125

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

BL.

If you are interested in the sensitive drilling attachment, I have the drawing at work and it is no big deal to run off an A1 print and post it to you. I drew the thing full size. I did draw up the thrust assembly which is missing from my first drawing . Let me know if you want it.

I have not used the the attachment. There is no more trouble involved in fitting the high speed head.

You scored a nice selection of accessories with the Riken. I wonder sometimes what was left behind when the Department of Supply off loaded the 13. I don't dwell on it too often.

BT

-

23rd January 2012, 10:28 PM #126

In addition to those pictured I got a good amount of tooling sundries with it, not riken related but still handy like arbours, taper adaptors, face & shell mills, er40 collets etc.

I suspect there would once have been a full compliment of the punch milling accessories, that accompanied my machine - but like you said it doesnt pay to dwell on these things.

-

7th April 2012, 12:00 AM #127

Hi everyone

I've been alittle busy recently, however Greg Q will be pleased to know I have'nt been raiding euro ebay for proprietary deckel stuff , so there should still be some left in all of europe for him & his fp1.

, so there should still be some left in all of europe for him & his fp1.

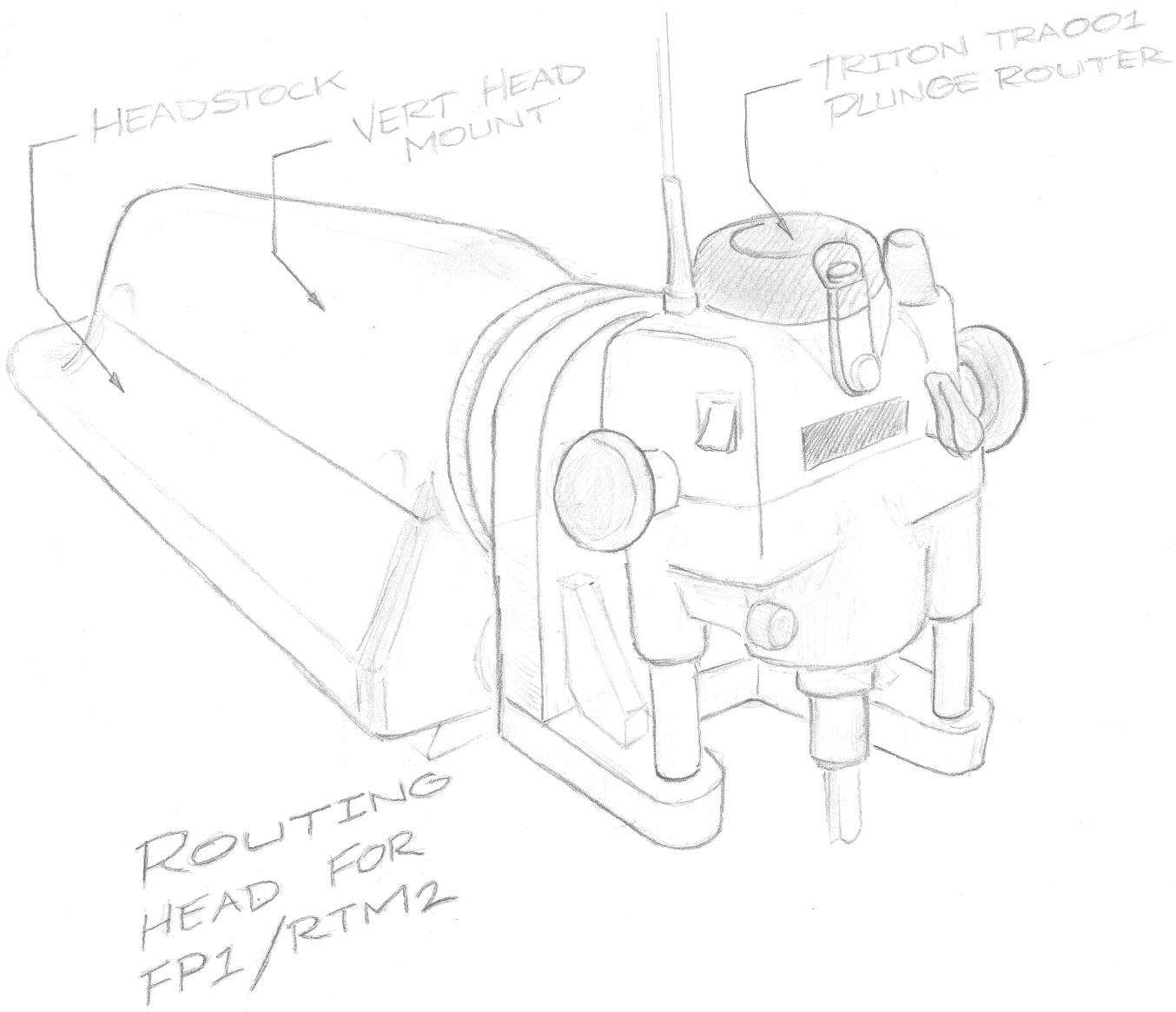

I'm looking to make an atachment for my riken mill, allowing me to mount my Triton plunge router inplace of the vert head.

The Idea of this being that I can then use my mill for some woodworking, cricket bat making, wooden hand plane & spokeshave making, riflestock inletting etc. and obviously that the spindle speeds should be nearer to those required for timber.

The following sketch is something near to what I envisage, and what would make things very simple would be if I could source one of the horizontal overarms for the fp1, or one of the verticle head mount castings that fit the guide ways in the headstock. I'd likely have to permanently modify whatever I find, so cant really use the originals I have.

I've no intention to use this attachment for anything other than timber (no metals).

To ensure this is a versatile addition to the rest of the machine, I'd look to keep the turning geometry roughly similar to the normal vert head, also probably make some kind of spindle extension.

If I use a modified overarm I should realistically have a lot more travel in the y-axis than the usual 150mm, by repositioning in the headstock guides.

I'd be interested in any input people might have, and if they may know of a source for the suitable parts/castings.

-

7th April 2012, 12:56 AM #128

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

Nice drawing Glen.

Is there a chance of burning the wood if the feed rates are too slow? It has been a while since I've used a router. Does the Riken have rapid traverse?

I reckon you would need to make up some sort of shroud to prevent the ingress of dust into the workings of the Riken. Too many oily nooks and crannies.

BT

ps. Just thinking a bit more about what you are trying to do... Karl Holtey, the infill plane maker, uses end mills in his Bridgeport to cut wood - http://www.holteyplanes.com/blog/

-

7th April 2012, 09:09 AM #129

Hi BT

Yeah, the ingress of junk isnt something that had been lost on me, rather I omitted the countermeasures from the pictorial view for clarity.

I figured I'd need:

- Aggresive Vac extraction directed right at the spindle, (our wet & dry workshop vac should do this nicely)

- To reinstate the concertina bellows to cover the bedways on the front of column. (I think this came off many years ago when the dro related stuff went on)

-And probably to make up somekind of fitted fabric cover for any exposed critical surfaces. something like what could be used on a lathe bed for toolpost grinding.

In this application I can see some advantages in having the head independantly powered.

The router (2400w) is infinitely variable between 8,000 & 20,000 RPM

The fastest feed on the mill's worktable is 24 1/8"/per minuter (my machine has imperial graduations) or 613mm/per minute - No rapid traverse, but Des was confident this top speed was comparable and could be used in liew of RT.

From memory this table feed is quicker than an Fp1 @ 475mm/Min.

I had been told that 1900rpm would be too slow for alot of the timber work I want to undertake, and I dont like to run the vert head of the riken at max rpm anyway.

I will have to do some calculations and closer research on what all this means.

Karl Holtey does real nice work, doesn't he. I'll try enquiring to him, about suitable speed @ feeds for timber.

-

7th April 2012, 10:11 AM #130

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

Yes Karl does some nice work, he being the self professed world's greatest planemaker. A bit of humility would not go astray...

( I had written a couple of paragraphs on how you could mount the router bracket to the overarm thinking the Deckel/Riken head attached to the overarm in a fashion similar to that of the 13. That was before I looked at some FP1 catalogue images. )

)

Rather than pursuing the expensive option of procuring another overarm, could you make a fabricated bracket that had either a steel or even an aluminium dovetail to fit the horizontal spindle casting?

I'ts funny how prejudices can be changed as a result of exposure to alternatives. I had found no appeal in the fabrication of components as an alternative to casting until I visited the workshop of Rod M and viewed his wondrous fabricated CNC machines.

I will be keen to hear more about the suitability ( or lack of ) of end mills for machining wood. Maybe others on this forum have tried it. My high speed head will run to 6000 rpm but like you Glen, I wouldn't want to run the machine flat out for an extended period.

BT

-

7th April 2012, 02:46 PM #131

An extra horizontal arm would be a nice thing, especially a longer one for a high speed head. I was thinking of one of those water cooled spindles as a super high speed head mounted to a longer overarm.

I own a high soeed head but it came on a truncated ram. If I was going to build one I think I'd try to sort out the dovetail in cast iron, then mount that part to a larger chunk of thick wall tube for the ram. The business end could simply be a welded on plate to accept your router mounting bracket.

I have used endmills on wood...mostly for mortices. They work fine. For that matter, router bits work on Aluminium too, properly lubricated. 8000 rpm isn't too much for small cutters.

The other suggestion I have is to fashion some kind of skirt below the router base with a brush type of arrangement. The dust extraction could be rigged to it so that all the dust was contained within the skirt for efficient extraction. Commercial CNC routers have something like that made from a brush material that is flexible yet efficient at containing the dust.

I wonder what kind of paste you'll end up with sawdust and 220 way oil?

Greg....who by the way is almost out of the euro parts chase. I have got to the point where the only other thing I'd kind of like is too rare and expensive to ever hope to obtain. But I'm good with that. What I'd really like is to get the damned thing running.It's all part of the service here at The House of Pain™

-

7th April 2012, 03:06 PM #132

.

.

- Join Date

- Nov 2008

- Location

- Perth WA

- Age

- 71

- Posts

- 5,650

-

8th April 2012, 09:10 PM #133

I had considered fabricating a support to mate with the dovetails in the headstock, I do like the idea of a long ram type setup (will certainly investigate it further) just initially I saw an amount of convenience in using an existing overarm - much of the work has been done, so I could have it functioning in a very short timeframe.

The router came fitted with a moulded perspex extraction hood that forms part of the base arrangment. The base will be mothballed, but the hood can likely be adapted for use on the router head bracket and like you say gain a bristled brush skirt around its perimeter.

there isnt much published info on the suitability of endmills for timber, I've seen video of them used on timber & devcon in the inletting stocks & bedding of actions etc. From this I couldn't realy determine speeds & feeds but It will probably largely come down to experimentation.

I'll also need to make a range of collets for endmills in between the 1/4" & 1/2" ones catered for by the router.

-

9th April 2012, 05:55 PM #134

Senior Member

Senior Member

- Join Date

- Oct 2008

- Location

- Cairns, Q

- Posts

- 351

B T,

I have a Blanchard lathe which is somewhat analogous to the situation you are discussing, in that it uses a travelling cutter head whose power unit is a 1/4" capacity 30000 (no load) RPM Makita laminate trimmer. The machine is used for making the roughly elliptical tapered shanks on spokes for twenties car wheels. The workpiece typically starts as a hardwood block, usually tallow wood or Queensland hickory, about 55mm x 35mm, and the finished tapered shank portion is typically about 150 mm long, varying from about 45 mm x 34 mm at the hub end to about 39 mm x 31mm at the outer end.

Since it is only used for this purpose, the machine is set up with a fixed feed speed of 45 mm/min, and a rotational speed of 17 RPM. These figures were arrived at using data from a Model Engineer magazine some years ago, where the author derived the operating speeds and feeds from inspection of a Blanchard fine-turning gun stock lathe, i.e second operation lathe, in the Science Museum, where he arrived at a spindle speed of 16 1/2 RPM and a feed of 2 inches/minute. The speed he quoted for the roughing lathe was quite a bit higher - cannot remember the exact figure now.

Before the spoke blank is transferred to the Blanchard lathe the corners are rounded off and a rough, well oversized taper established manually on a normal wood lathe to make the work easier for the trimmer. The tallow wood particularly seems to be very abrasive, and carbon steel turning tools need honing again after roughing two spoke blanks.

Experience has shown that a 1/2" round nose router bit is the most suitable tool for shaping the spoke shank. A square end router bit leaves a very distinct vertical step between successive revolutions, while the round nose bit leaves a shallow rounded 10 TPI (the leadscrew pitch) groove which is easily sanded out. Cuts can be up to 3/4" on diameter on the large diameter of the taper, which really tests the laminate trimmer!

To cut the square shouldered round tenon on the rim end of the spoke where a plunge cut is required I have had to resort to using an ordinary 1/4" HSS slot drill, because suitable centre cutting 1/4" shank 1/2" router bits are apparently no longer still made, several former manufacturers claiming that solid carbide bits in this size are too fragile, and they had too many complaints. Attempts to use a normal 1/2" router bit, which is not centre cutting, resulted in a barrel shaped tenon with a burnt band in the centre.

For the tenons on the last batch of 6 wheels (72 spokes) I used a 1/4" HSS slot drill which was not blunt, but had previously been used on steel. After three plunge cuts and a light hand-fed lengthwise finishing-to-size cut on each 5/8" diameter tenon, the slot drill was still cutting cleanly and leaving a reasonable finish on the workpiece, so there does not seem to be any reason why at least slot drills and end mills should not be used regularly on timber, and still have an acceptable life.

And yes, the mixture of sawdust and way oil does make a fearsome mess which gets into every nook and cranny on the machine! My el-cheapo dust collector has no hope of coping with the amount of dust produced, which coats everything in the shed, and is sudden death on exposed tools. It also fills the C purlins in the roof so it descends in clouds for days after the Blanchard has been used with every gust of wind. I always use a pressurised helmet when using the machine.

We do seem to have diverged slightly from the original topic!

Frank.

-

14th April 2012, 12:04 AM #135

Hi Franco,

Thanks for sharing your experience re: endmill use on timber - I'll conduct some of my own trials on some timber samples and get an idea of realistic removal rates & realistic finish expectations, in the mills current unmodified configuration (90-1900 RPM - rather low).

Weighing up the quality of the results I'll then decide if building the router head is even warranted.

I know it would be very hard to do a good job of efficient dust extraction on your travelling head setup, but do you feel even if I were to do my utmost to protect the machine via extensive vacuum hoods & slide covers etc that there would still be a percentage that avoids extraction? and ends up accumulating in hard to reach, semi critical areas?

i.e Even if I take every countermeasure in the defence of my machine when the routing head is installed does it have to be a foregone conclusion that it will get blanketed in the dust and inevitably cause damage? because if damage cant be avoided obviously i'd want nothing to do with it.

Similar Threads

-

Cincinnati Monoset T and C Grinder Brochure

By Anorak Bob in forum METALWORK FORUMReplies: 9Last Post: 27th July 2011, 11:24 PM -

Hardinge DSM59 turret lathe?

By DoctorWu in forum METALWORK FORUMReplies: 9Last Post: 18th July 2011, 07:58 PM -

260 Attachments- Scanned Brochure

By Anorak Bob in forum THE HERCUS AREAReplies: 4Last Post: 14th July 2011, 11:50 PM -

Cincinnati Shaper Brochure

By Anorak Bob in forum METALWORK FORUMReplies: 17Last Post: 22nd June 2011, 01:54 PM -

Agathon Tool Grinder Brochure

By Anorak Bob in forum METALWORK FORUMReplies: 8Last Post: 5th April 2011, 05:18 PM