Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 61 to 75 of 92

-

21st July 2011, 11:58 PM #61

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Ray,

Looks great and a little scary at the same time lol

Do you think the door will make much difference?

Have you kept it at 1250 long enough to see what sort of cycle time you are getting? If your maths is right it should be something just under 50% right?

BT, you've got further in the book than I have. I had a quick flick and then went back to MTR. The tour isnt helping my reading time lol

Stuart

-

21st July 2011 11:58 PM # ADSGoogle Adsense Advertisement

- Join Date

- Always

- Location

- Advertising world

- Posts

- Many

-

22nd July 2011, 12:22 AM #62

Hi Stuart,

+1 For Scary, I kept thinking of all the things that might go wrong...

We kept it at 1250 for about 1/2 an hour, then dropped to 1200 for an hour, I didn't measure the duty cycle, it seemed to vary quite a bit as the PID controller did it's thing.

I think having the door seal properly will make a difference, but probably not a huge amount.

There's a tapered reamer milled from O1 that we will heat treat as a test tomorrow.

I forgot to mention earlier, that I got some Aqua Quench 251 polymer quenchant... good stuff, no flames or fumes and non toxic. 20% concentration is same cooling rate as oil.

Regards

Ray

-

22nd July 2011, 09:04 AM #63

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

looks great..fantastic job Ray

what night is pizza night

-

24th July 2011, 08:18 PM #64

Hi All,

The first burn-out also burnt out the silicon insulated wires and terminals. The wires crumbled and broke off as soon as they were touched

Post Mortem..

Two things that we did wrong, first problem is that we stupidly put a layer of ceramic fibre insulation between the wiring and the outer shell. So there was no way for the heat to dissipate from that area, the second problem was I used silicone insulated wire (rated at 150C) instead of a higher temperature rating, (which is what I should have used in the first place.)

My best guess is that area got up to 300-400C probably several hours after the furnace had been powered down, as the temperature came to equilibrium.

Another thing that failed unexpectedly was the crimp teminals, which were tin plated copper rather than a high temperature nickel plated steel type.

I've rebuilt the wiring temporarily using a mil-spec teflon insulated wire and removed the crimp terminals. This was so we could heat treat an O1 tapered reamer that needed to be done.

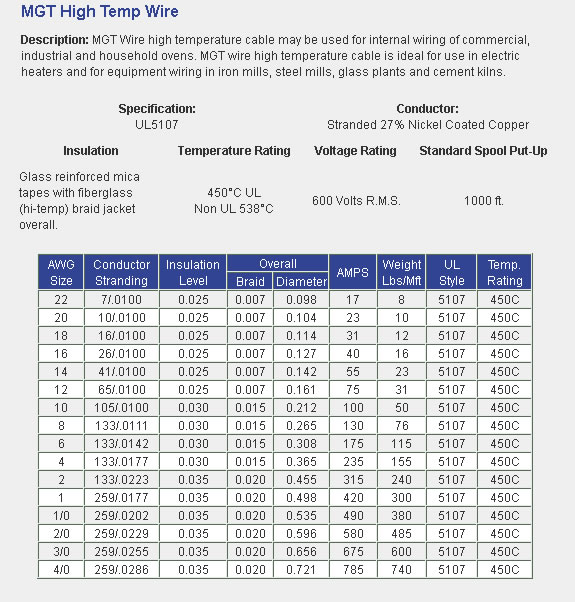

I'm going to rewire it with better MGT (UL5107) rated wire which is good for 538 C, it uses glass reinforced mica tape with fibreglass jacket.

The ceramic insulation layer between the wiring and the outer shell is removed.

Still undecided about using the terminals but I'll get some nickel plated steel crimp terminals (good for 480C) and decide later whether or not I should use them...

One step forward , two steps back...

Regards

Ray

Hi Eskimo, Pizza night is delayed while equipment upgrades are in progress...

-

25th July 2011, 02:00 PM #65

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

Hi Ray,

So I'm not the only one that has those moments then?

moments then?

I'd thought by the early pictures you were leaving them uncovered(with the insulation that is).

Wouldn't most of the heat be coming back down the element? One thing I've seen used in a similar situation is a heatsink on the bolt to dissipate that heat so it doesn't get to the insulated wiring. Just a piece of 3mm Alum say 25mm sq with a hole in it for the bolt, it goes between the element and the lug. Get what I mean?

That may save you the need of special wire.

Stuart

-

25th July 2011, 02:34 PM #66

Hi Stuart,

I think it would have been ok, if we hadn't put that extra layer of insulation between the wiring and the shell...

Here is the specs for MGT class wire

I found some on ebay from this seller.. #12 HIGH TEMPERATURE MGT ELECTRIC WIRE HEATERS PER FOOT | eBay

The price from Digikey for a 100ft roll was just shy of $600.... http://search.digikey.com/scripts/Dk...265%20TN005-ND

http://search.digikey.com/scripts/Dk...265%20TN005-ND

Regards

Ray

-

25th July 2011, 03:41 PM #67

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

-

25th July 2011, 05:28 PM #68

SENIOR MEMBER

SENIOR MEMBER

- Join Date

- Oct 2007

- Location

- Sydney

- Posts

- 2,340

Ray I'm unsure of where these terminals are precisely located, but are you able to make up some form of cover with the terminals on it, then from there simply run bare solid copper wire to your standoffs?

It's not uncommon to see old electric kitchen ovens dumped somewhere, you should be able to locate a suitable donor for some high temp wire.

Pete

-

11th August 2011, 11:14 PM #69

Hi All,

Just an update on wiring. The MGT wire arrived today, so I've rewired the back panel.

The wire construction is interesting, the conductors are nickel plated copper, and the insulation is mica layers wrapped around the core with a braided fibreglass cover. The UL rating is 450 C, and the non-UL rating is 538 C.

Also the high temperature crimp terminals arrived, and are nickel plated steel.

The crimp terminals I used earlier which vaporized were tin plated copper. Well, anyway the tin coating was nowhere to be found...

All being equal we are back to being rated to 1250 C (inside the furnace that is.. )

)

The ramp/soak controller arrived and the modbus comms manual supplied was in Chinese, so I've transated it with the help of google translate. (that was fun! )

)

I now have linux drivers working for programming the controller.

With a bit of luck, I hope to have the full version of the ramp/soak controller up and running next week.

Regards

Ray

-

12th August 2011, 08:32 AM #70

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

[QUOTE=RayG;1348653]

The control system is one of these... Temperature Controller PID Kiln Ramp Soak 64-Setpoints | eBay

The main reason for choosing that particular one is that it has a modbus interface, so I can interface it to an embedded linux box with mysql database and wifi web access.

/QUOTE]

What!?

does that mean your gunna control it with your mac?

-

23rd August 2011, 12:03 AM #71

Hi Eskimo,

Well, I could use the mac, but I am actually setting it up so I can use the iPhone... while it might seem like overkill, having remote monitoring is a good thing for a furnace, typical cycle times might extend out to quite a few hours, so, this lets me keep an eye on things without having to be there all the time babysitting the kiln. I seem to remember reading something about pottery makers, spending all night sessions babysitting kilns.

Anyway, here is the current update. Some more parts arrived, notably the SSR's and the SSR heatsinks, so I got the control panel layout roughed in, the din rail PSU's are not the right ones, but they are the right size, the 12V one hasn't arrived yet.

So this is how it looks at the moment..

The SSR's (Solid State Relays) are 25A from ebay, the main furnace has 2 x 2.4Kw elements, and the third SSR is for a future tempering furnace, that will go into the same frame. Each element has it's own circuit breaker and independant 10A supply.

The SSR's are from $A5.06ea eBay Australia: Buy new & used fashion, electronics & home d

The SSR heatsinks $A5.73ea eBay Australia: Buy new & used fashion, electronics & home d

The CPU is a Kontron (good German brand) JREX-PM, it's nice little embedded PC that runs off compact flash instead of a hard drive. A left over from a previous life..

Regards

Ray

-

23rd August 2011, 01:10 AM #72

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2010

- Location

- Melbourne

- Posts

- 7,775

You just need a one legged stool Ray. I'm told thats how you stay awake watching a kiln.

Looks pretty. (my crimper has turned up so I'll be able to pretty up my vsd soon)

Why three relays?

Stuart

p.s. Did you edit your post Ray or am I just going blind? lol nvm on the 3 relay question

Last edited by Stustoys; 23rd August 2011 at 11:38 AM. Reason: p.s.

-

23rd August 2011, 07:03 AM #73

Pink 10EE owner

Pink 10EE owner

- Join Date

- Aug 2008

- Location

- near Rockhampton

- Posts

- 4,304

Gee Ray I hope you are licensed like me doing all that electrical work...

Light red, the colour of choice for the discerning man.

Light red, the colour of choice for the discerning man.

-

23rd August 2011, 09:15 AM #74

Hey Ray, Glad it's you paying for the Electricty to run it.

-

23rd August 2011, 09:26 AM #75

GOLD MEMBER

GOLD MEMBER

- Join Date

- Jul 2006

- Location

- Adelaide

- Posts

- 2,680

of course..an iphone...why didnt I think of that...what would one do without their iPhone..or should I say..what cant one do with an iPhone

very impressive board & layout Ray.

you must have a lot of knowledge in this area

Similar Threads

-

Small Furnace

By Foccacia in forum THE FOUNDRYReplies: 9Last Post: 31st May 2011, 11:24 PM -

Small furnace

By Woodwould in forum METALWORK FORUMReplies: 5Last Post: 12th July 2010, 02:53 PM -

small heat treatment oven

By .RC. in forum METALWORK FORUMReplies: 22Last Post: 25th March 2010, 07:42 PM -

Oil Burners for Casting Furnace.

By impalabazz in forum THE FOUNDRYReplies: 42Last Post: 2nd June 2007, 11:04 AM -

Furnace Filters.

By Caliban in forum WOODWORK - GENERALReplies: 10Last Post: 16th July 2004, 10:36 PM